Insulation and voltage resistance experiment method of electrolytic direct-current system

An experimental method and DC system technology, applied in the field of electrolytic DC system insulation withstand voltage, can solve the problems that the electrolytic DC system insulation withstand voltage test method has not been reported, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

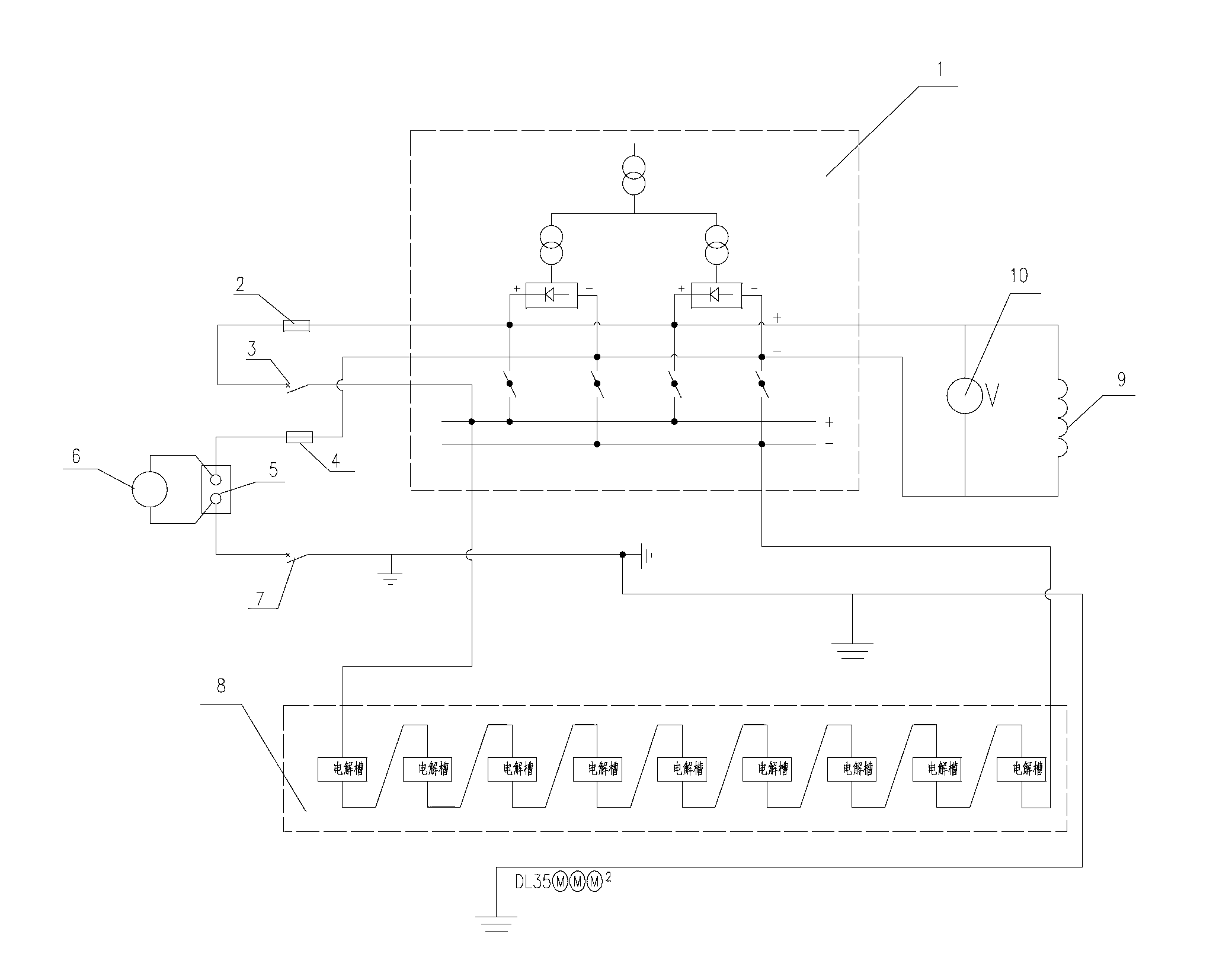

[0017] Such as figure 1 As shown, an electrolytic DC system insulation withstand voltage test method, in which the rectifier unit 1 is composed of a rectifier cabinet A and a rectifier cabinet B; the positive busbars of the rectifier cabinets A and B are connected in parallel, and the rectifier cabinets A and B are output The negative busbars are connected in parallel; the positive busbar output ends of the parallel rectifier cabinet A and B are connected to the positive end of the electrolysis chamber 8 through a cable; the paralleled rectifier cabinet A, B positive busbar output ends are also connected to the first fuse 2 through a cable The other end of the first fuse 2 is connected to the first air switch 3, and the other end of the first air switch 3 is connected to the positive terminal of the electrolysis chamber 8; the output ends of the negative busbars of the rectifier cabinets A and B in parallel are connected to the One end of the second fuse 4 is connected, the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com