Device for measuring wind speed and direction

A technology of wind speed, wind direction and mounting seat, which is applied in the direction of measuring device, fluid speed measurement, speed/acceleration/impact measurement, etc. It can solve the problems of regular maintenance and calibration, limited application, high price, etc., and achieve accurate and reliable measurement accuracy. The effect of overcoming technical difficulties and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

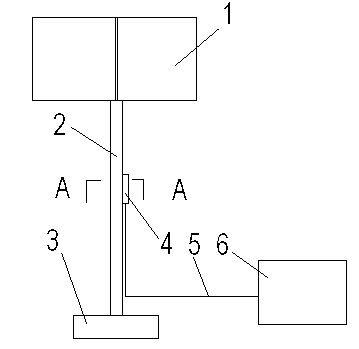

[0027] The windward force receiving body, the deformation rod 2 and the mounting seat 3 are assembled together sequentially from top to bottom; the sensor 4 is installed on the deformation rod 2, and the output end of the sensor 4 is electrically connected to the host computer 6 through a data line 5; the windward The force-receiving body is composed of two mutually perpendicular vertical plates 1 to form a rigid structure, and the two vertical plates 1 are three-dimensionally vertical and / or vertical to each other. The cross-section of the position where the sensor 4 is installed on the deformation rod 2 is rectangular. The sensors 4 installed on the four surfaces of the deformation rod 2 are tensile strain gauges 7, and the tensile strain gauges 7 are arranged on the same cross section.

Embodiment 2

[0029] On the basis of Embodiment 1, the sensor 4 installed on the deformation rod 2 is a pressure strain gauge 8 . Tensile strain gauges 7 and compressive strain gauges 8 on each face are arranged on the same cross section.

Embodiment 3-4

[0031] It is basically the same as the corresponding embodiment 1-2, except that the outer contour of the riser 1 is a rectangle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com