Automatic determinator for fluffy performance and water absorbency of fluff pulp

A water absorption performance and measuring instrument technology, which is applied to the automatic tester for fluffy pulp fluffy performance and water absorption performance, and the field of fluffy pulp fluffy performance and water absorption performance measurement. problem, to achieve the effect of extensive practical and promotional value, simple structure, and accurate test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

[0024] This instrument is mainly used to measure the fluffy height, bulkiness, water absorption speed and water absorption of fluff samples.

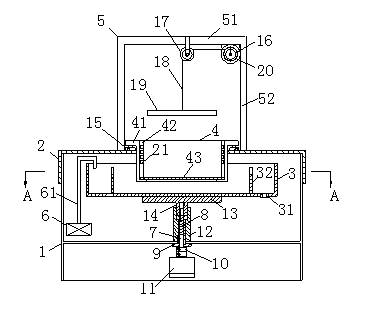

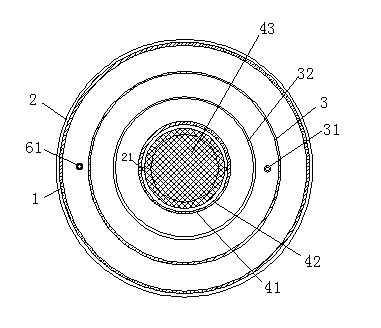

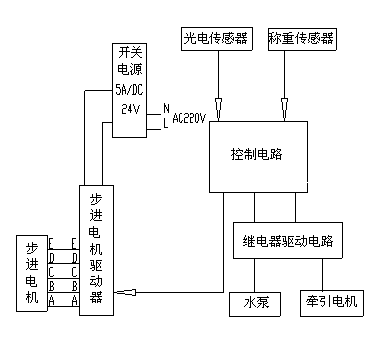

[0025] like figure 1 , figure 2 As shown, the main body of the measuring instrument is composed of a water storage tank, a top cover of the water tank, a water suction tank, a lifting adjustment part of the water suction tank, a sample plate, a scale bracket and a water pump; the water storage tank 1 is a circular tank structure, and the water storage tank 1 is a water suction tank 3 , the water suction tank 3 is a circular tank with a diameter smaller than that of the water storage tank 1, the water suction tank 3 is provided with an overflow partition 32, the upper mouth of the water suction tank 3 has a water pump outlet pipe 61, and a port of the water pump outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com