Head baffle of plate-fin heat exchanger

A technology of plate-fin heat exchanger and head, which is applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., which can solve the problem of less application, complicated and over-dense arrangement of openings, and reduced baffle strength and other issues, to achieve the effect of expanding the scope of application, improving logistics distribution, and improving operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the structure and working principle of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

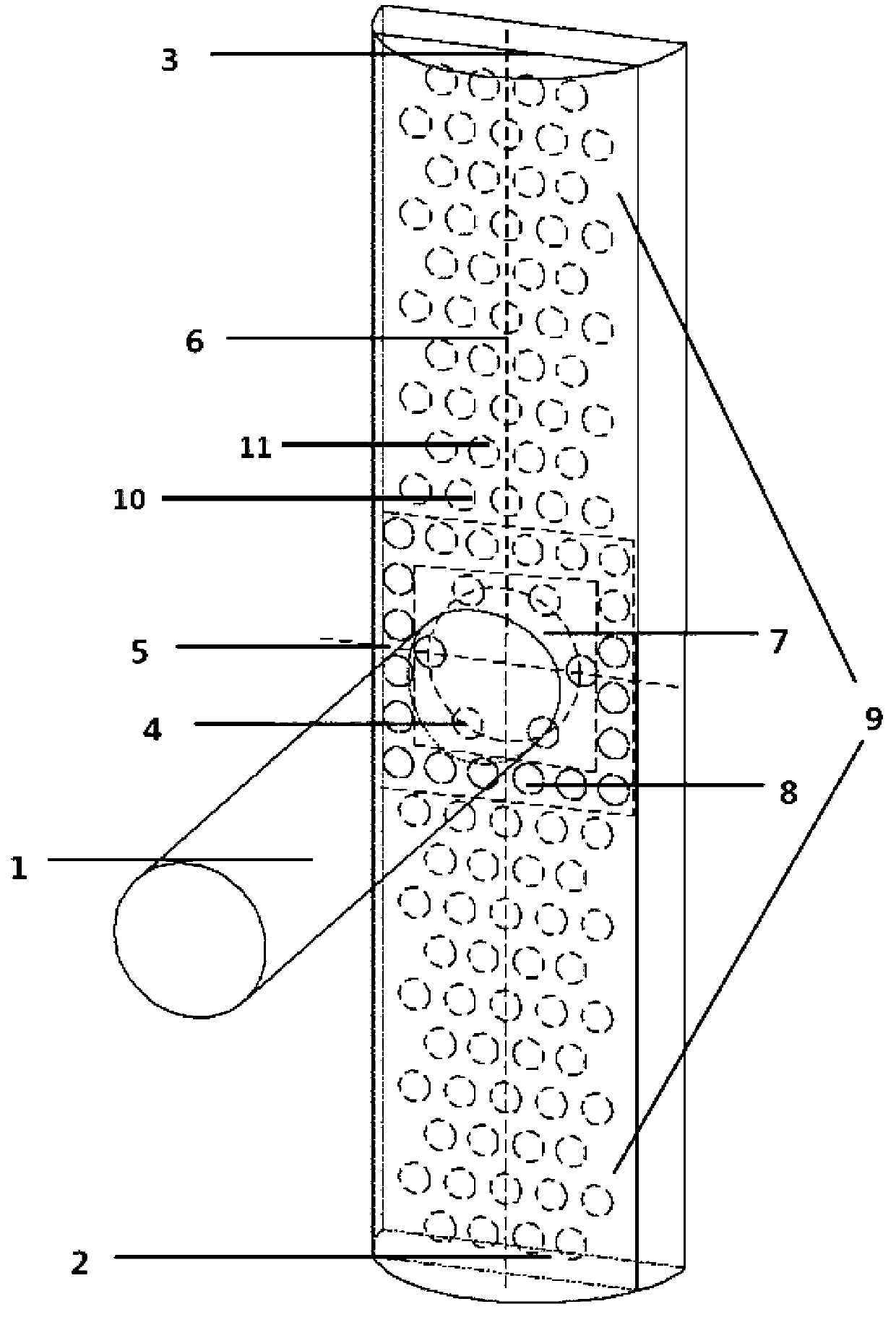

[0018] see figure 1 , according to the technical solution of the present invention, a baffle structure suitable for the head of a plate-fin heat exchanger, the rectangular baffle 3 is installed at 1 / 2 of the arc-shaped structure 2 of the head, and the recommended thickness of the baffle is 1 ~3mm, in actual application, it can be appropriately increased or decreased according to the fluid properties, Reynolds number and gas-liquid ratio and other parameters.

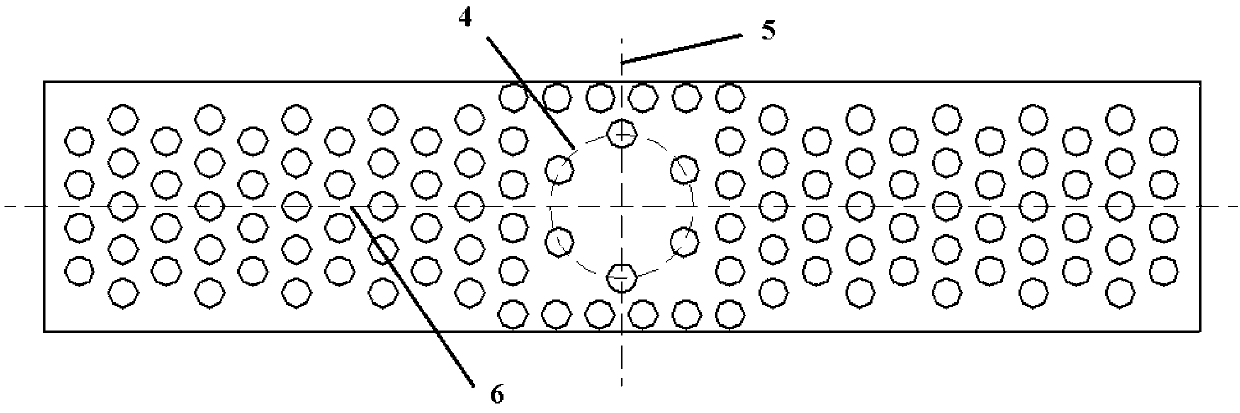

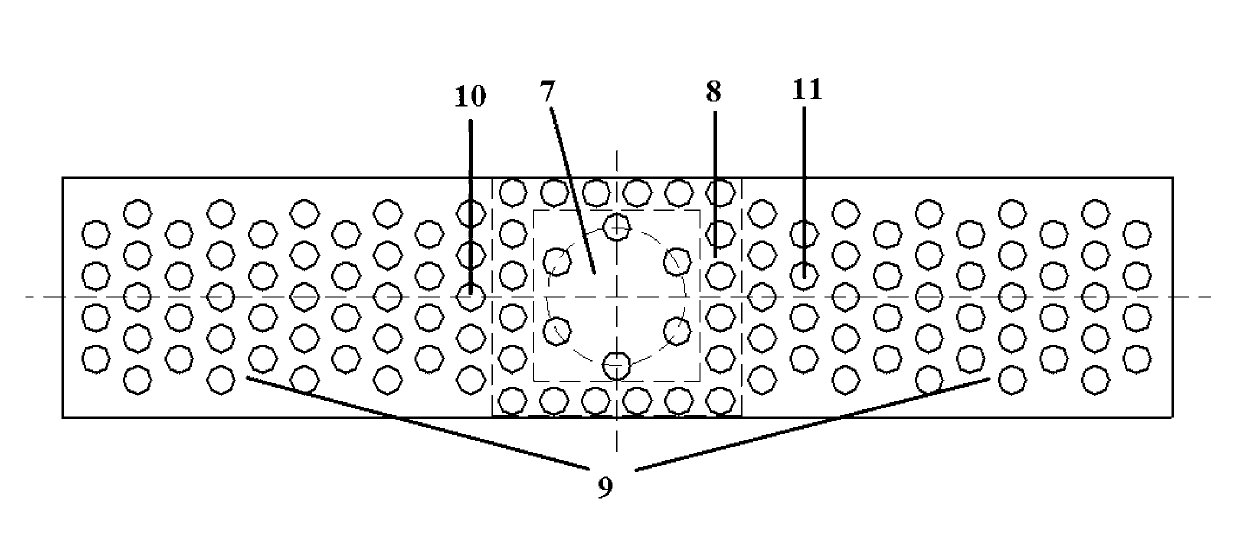

[0019] Such as figure 2 and image 3 As shown, a plurality of through holes are distributed on the baffle plate 3, the diameter of the through holes is 1 / 5 of the diameter of the inlet pipe 1, and the distance between the horizontal and vertical holes is 1 / 2 of the diameter of the through holes. The arrangem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com