Drying device and method of lithium-ion power battery pole piece

A power battery and drying device technology, applied in battery electrodes, progressive dryers, drying solid materials, etc., can solve problems such as battery consumption, difference in moisture content of rolled pole pieces, night leakage, etc., to improve safety and avoid consumption. Effects of differences in electrolytes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

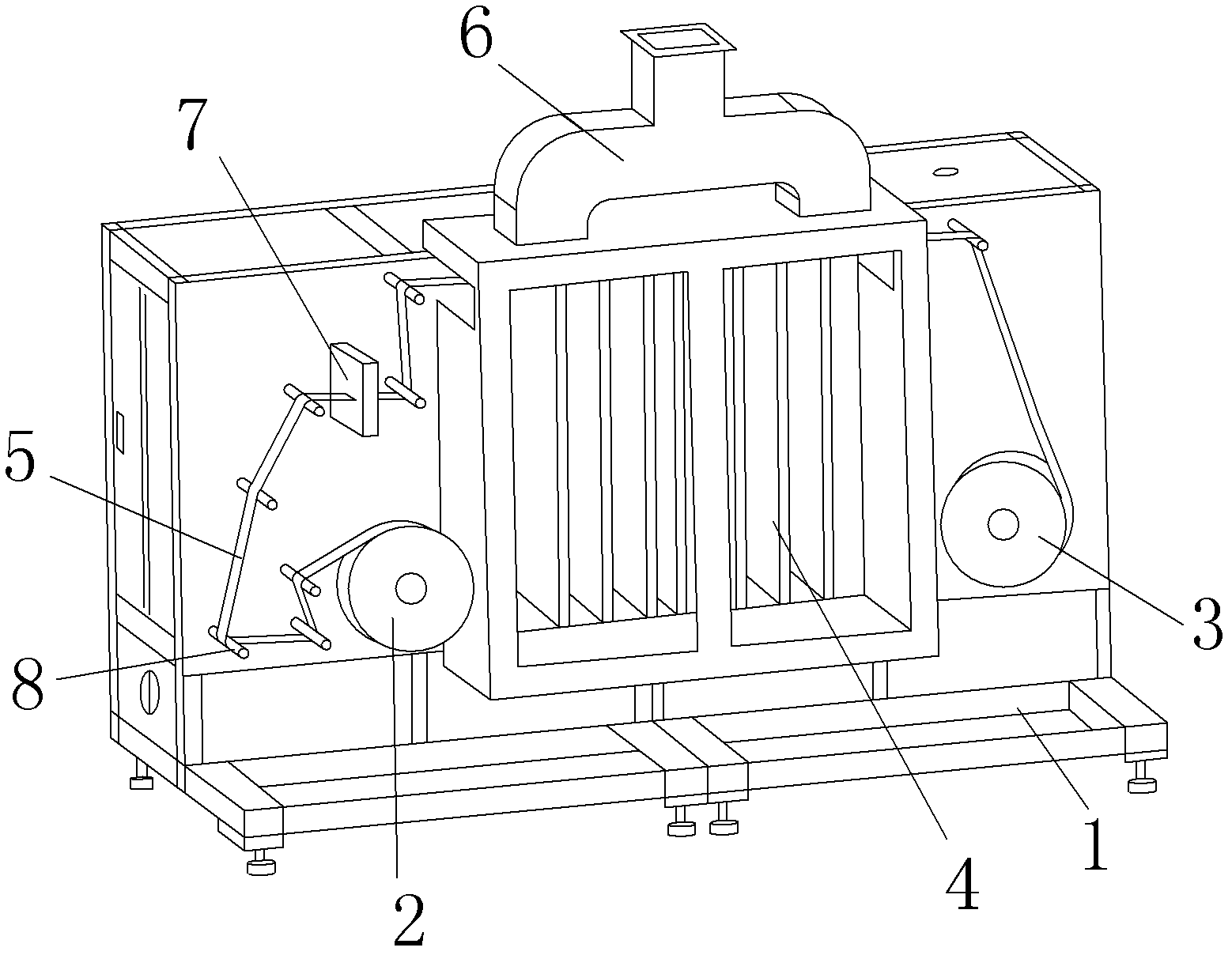

[0033] see figure 1 , figure 1 It is a schematic structural diagram of a drying device according to an embodiment of the present invention. The drying device for pole pieces of lithium-ion power batteries of the present invention is suitable for drying all pole pieces of lithium-ion power batteries. Including a support 1 and an unwinding mechanism 2 installed on the support 1, a winding mechanism 3 and an infrared heater 4, the lithium ion power battery pole piece 5 is wound on the unwinding mechanism 2 and the lithium One end of the ion power battery pole piece 5 is fixed on the unwinding mechanism 2, and the other end of the lithium ion power battery pole piece 5 is fixed on the described winding mechanism 3, and the lithium ion power battery pole piece 5 is on the Driven by the winding mechanism 3, it passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com