Combustion module of kerosene warmer

A technology for combustion modules and heaters, which is used in household heating, space heating and ventilation details, sustainable buildings, etc., and can solve problems such as inability to release heat according to actual use needs, inability to continuously adjust, and poor adaptability to the use environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

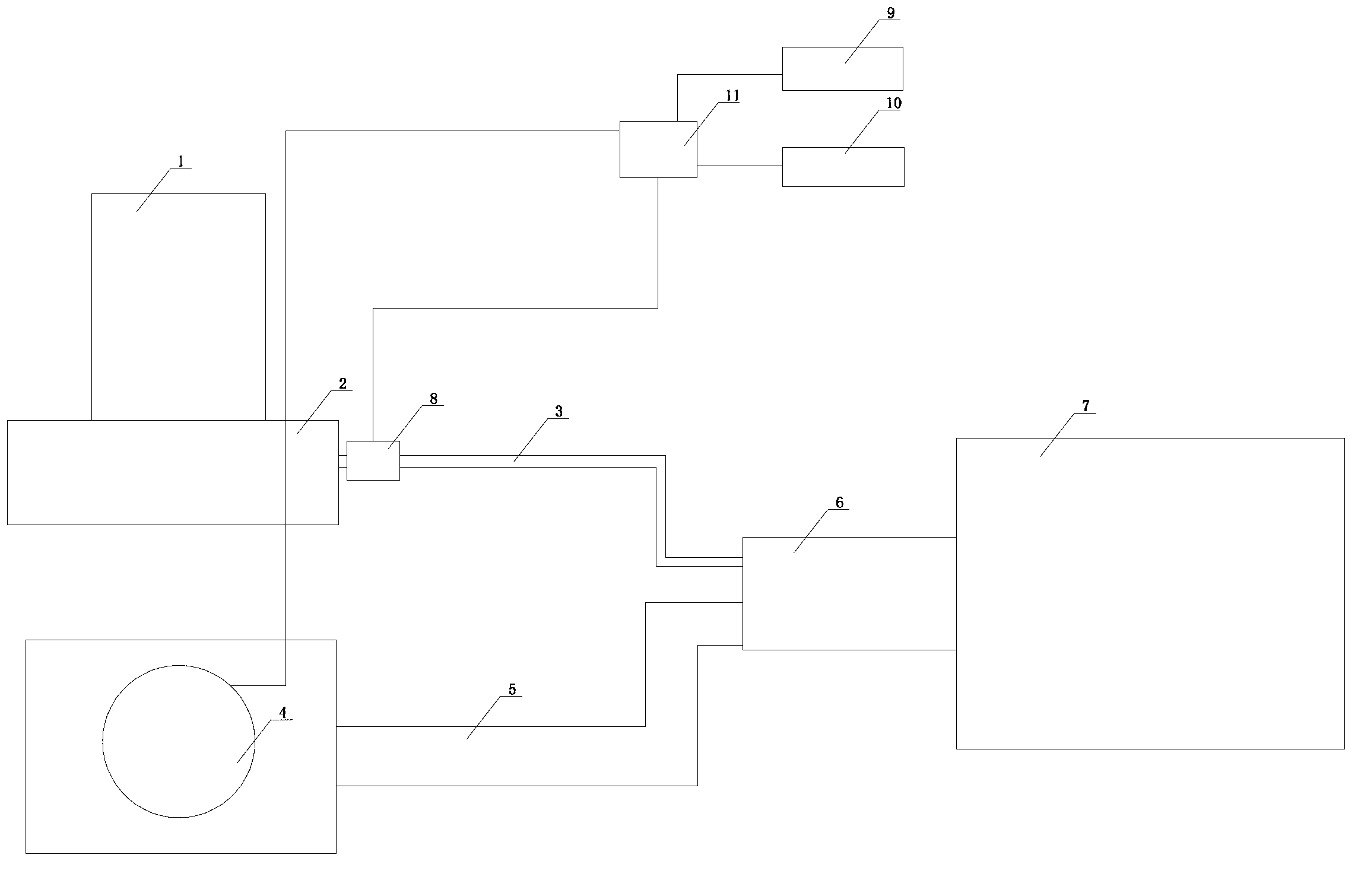

[0010] Combine below figure 1 The present invention is further described.

[0011] The combustion module of the kerosene heater of the present invention comprises a fuel tank 1, a fuel tank mount 2, an oil pipe 3, a fan 4, an air pipe 5, a mixing chamber 6, and a combustion chamber 7. The fuel tank 1 is installed upside down on the fuel tank mount 2, and the fuel pipe 3 One end is connected to the fuel tank mounting base 2, the other end of the oil pipe 3 is connected to the mixing chamber 6, one end of the air pipe 5 is connected to the fan 4, the other end of the air pipe 5 is connected to the mixing chamber 6, and the mixing chamber 6 is connected to the combustion chamber 7. It also includes Electric control unit; the oil pipe 3 is provided with a solenoid valve 8 for controlling the amount of oil output by the oil pipe 3, and the fan 4 adopts a speed-regulating motor; the solenoid valve 8 and the speed-regulating motor are respectively electrically connected to the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com