Walking type backfill soil mixing device

A backfilling and walking technology, applied in clay preparation devices, cement mixing devices, mixed operation control devices, etc., can solve the problems of reduced construction efficiency, waste of manpower, low efficiency, etc., to improve construction efficiency, reduce construction time, The effect of reducing labor waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the process of building construction, the entire large-scale construction site is wide and scattered, and the earthwork is often transported off-site, backfilled on the site, transporting a single material to the mixing place and transporting the mixed material to the construction site not only wastes time, but also mixes the earthwork on site. The quality is difficult to guarantee, the efficiency is low, and there is a lot of dust on site, which does not meet the requirements of civilized construction on site, and wastes manpower, lengthens the overall construction time, and reduces construction efficiency.

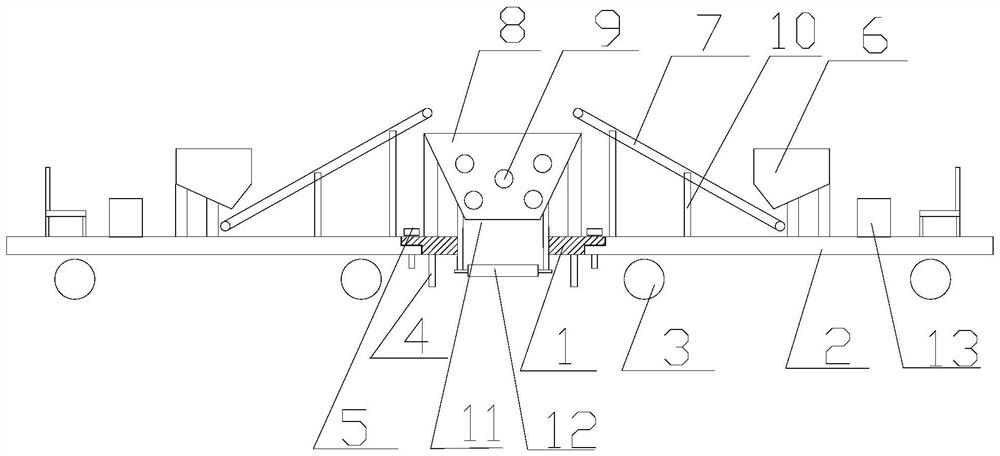

[0030] In view of the above problems, the present invention provides a walking backfill soil mixing device, and specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0031] The following description of the exemplary embodiments is merely illustrative in nature and in no way is taken as any ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com