Intermediate drive dense ball shafting mechanism

An intermediate drive and dense bead technology, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems that cannot meet the special requirements of intermediate drive mechanical equipment, etc., and achieve the advantages of bearing life, high rotation accuracy, and force resistance. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

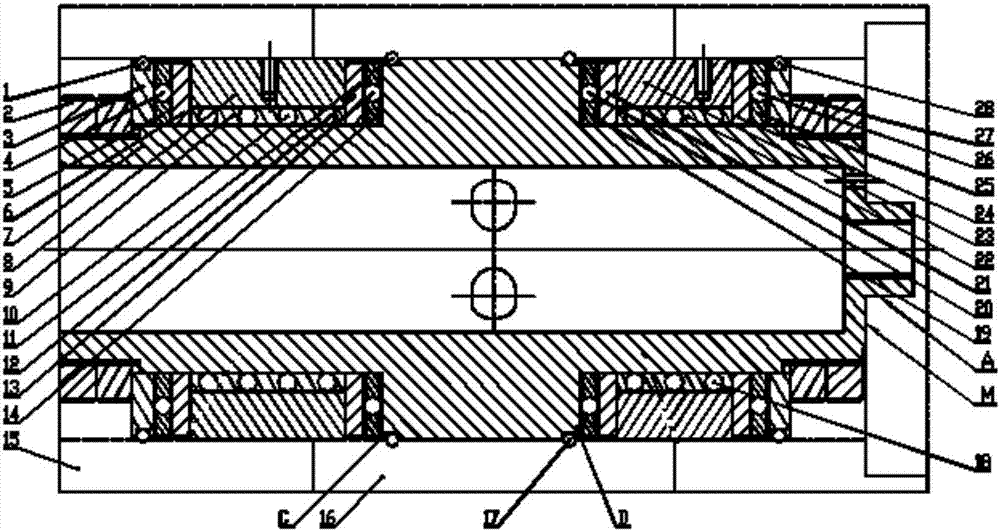

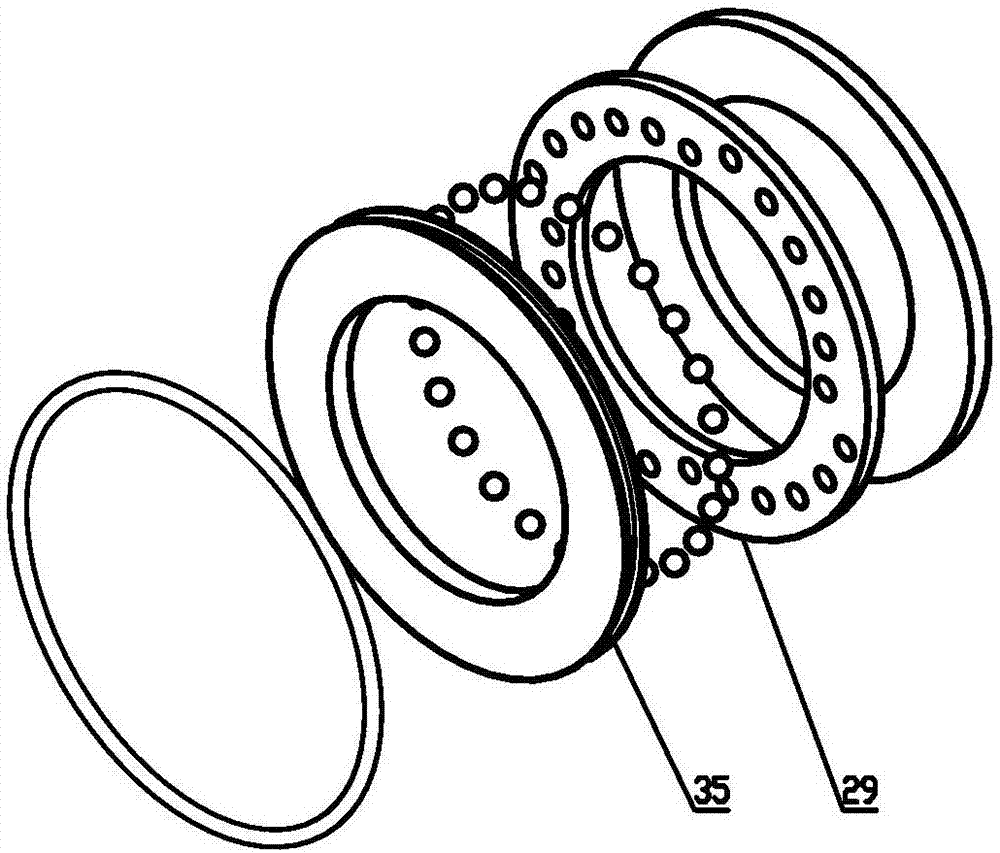

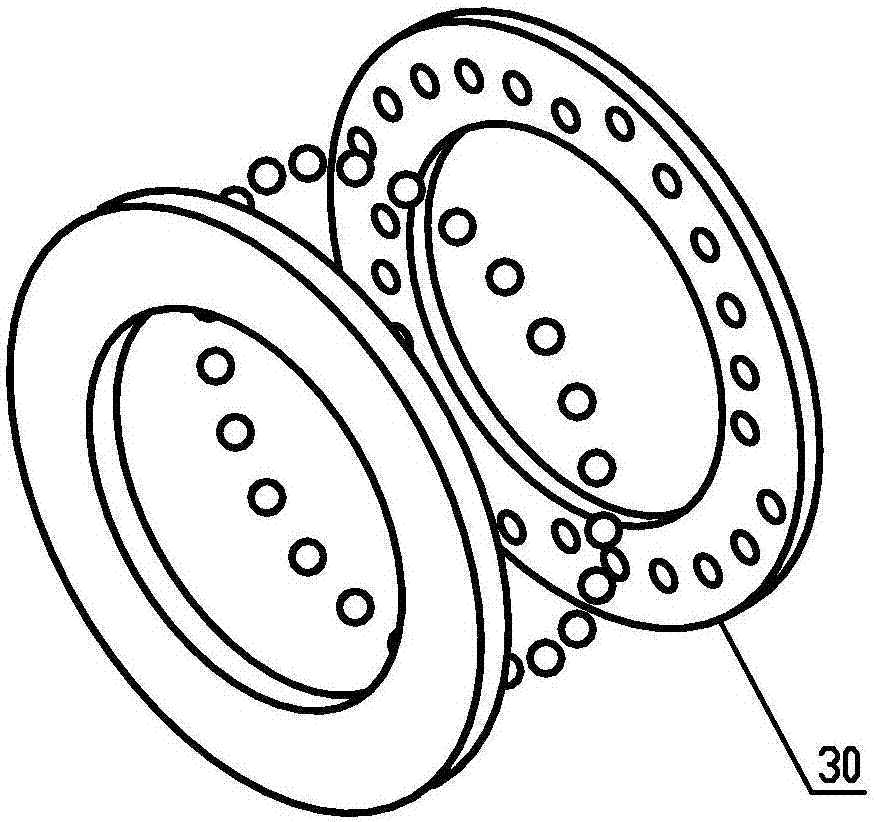

[0044] see figure 1 , which is a structural schematic diagram of the first embodiment of the intermediate drive type dense ball shafting mechanism of the present invention. The intermediate drive type dense ball shafting mechanism includes the axial thrust dense ball shafting I29 (see figure 2 ), axial thrust dense ball shafting II30 (see image 3 ), axial thrust dense ball shafting III31 (see Figure 4 ), axial thrust dense ball shafting IV32 (see Figure 5 ) and radial dense ball shafting I33 (see Figure 6 ), radial dense ball shafting II34 (see Figure 7 ), transmission shaft 7 and round nut 2,

[0045] see figure 1 and figure 2 ,and figure 2It is a three-dimensional structure schematic diagram of the axial thrust dense ball shafting I of the intermediate drive type dense ball shafting mechanism of the present invention. The axial thrust den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com