Electric lifting wire pole

A utility pole and electric technology, which is applied in the field of power transmission and transformation, can solve the problems of insufficient mechanical strength, bulky utility poles, and insufficient impact strength, etc., and achieve excellent impact resistance and insulation performance, high resource recovery rate, and simple and light structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

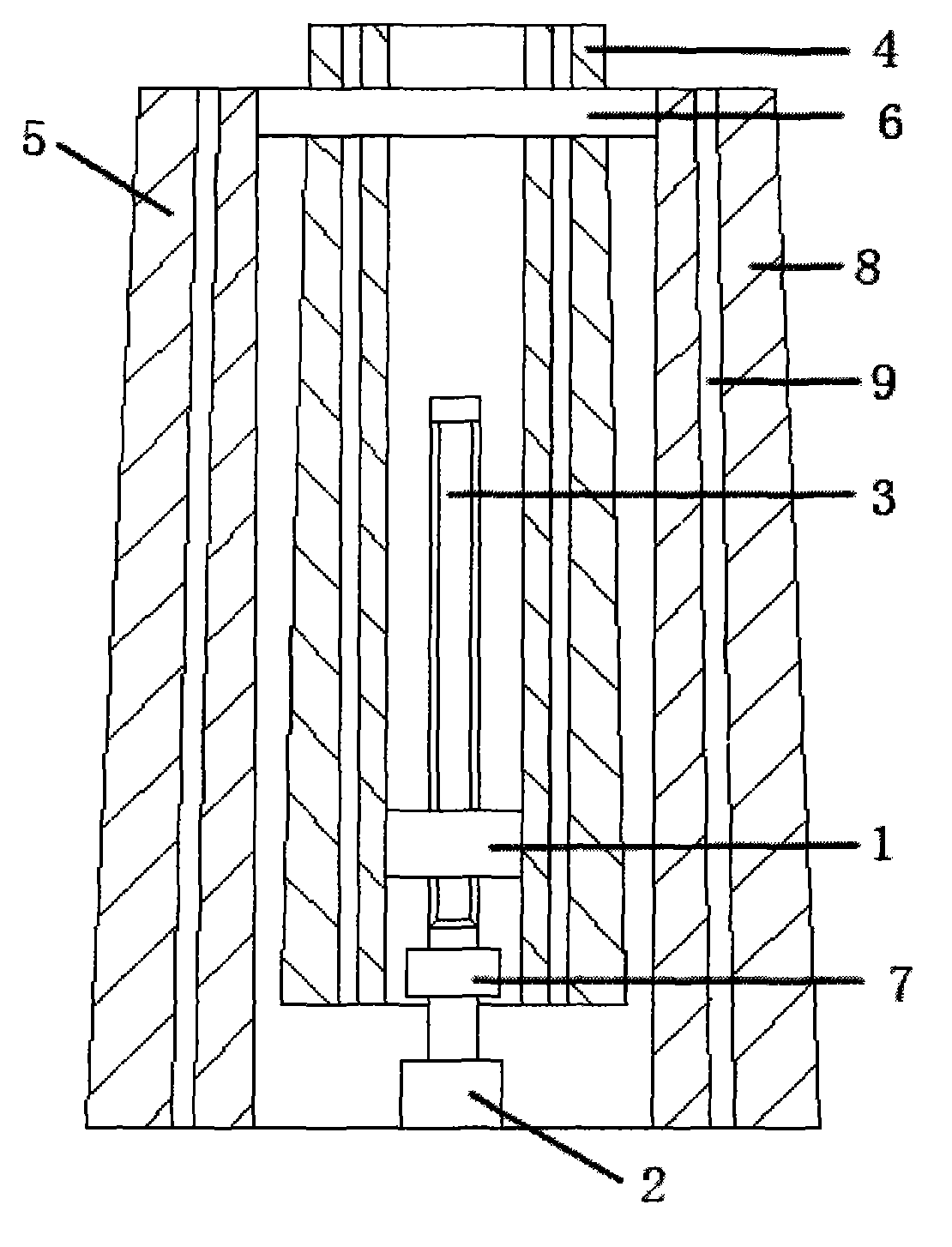

[0014] Such as figure 1 As shown, an electric lifting utility pole includes a utility pole body. The utility pole body is composed of at least two utility pole bodies, a threaded transmission sleeve 1, a driving motor 2 and a lead screw 3. One of the utility pole body A utility pole body is nested inside another utility pole body, a positioning block 6 is set between the inner utility pole body 4 and the outer utility pole body 5, and the inner wall of the threaded transmission sleeve 1 is provided with a smooth threaded outer wall and is aligned with the inner wall of the utility pole. Reliable connection, the drive motor 3 is reliably connected to the foundation of the utility pole body and connected to the lead screw 3 through the coupling 7, the lead screw 3 is reliably connected to the threaded transmission sleeve 1 and threaded, and the utility pole body is composed of the base material 8 and the The steel reinforcement rib 9 is formed, and the steel reinforcement rib 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com