Dislocation-free expansion joint node for box type profiled steel sheets

A technology of profiled steel plates and expansion joints, applied to roofs, building components, buildings, etc., can solve the problems of vertical misalignment of box-shaped profiled steel plates, pull-off roof panels, roof panel leakage, etc., to eliminate vertical misalignment, The effect of prolonging the service life and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

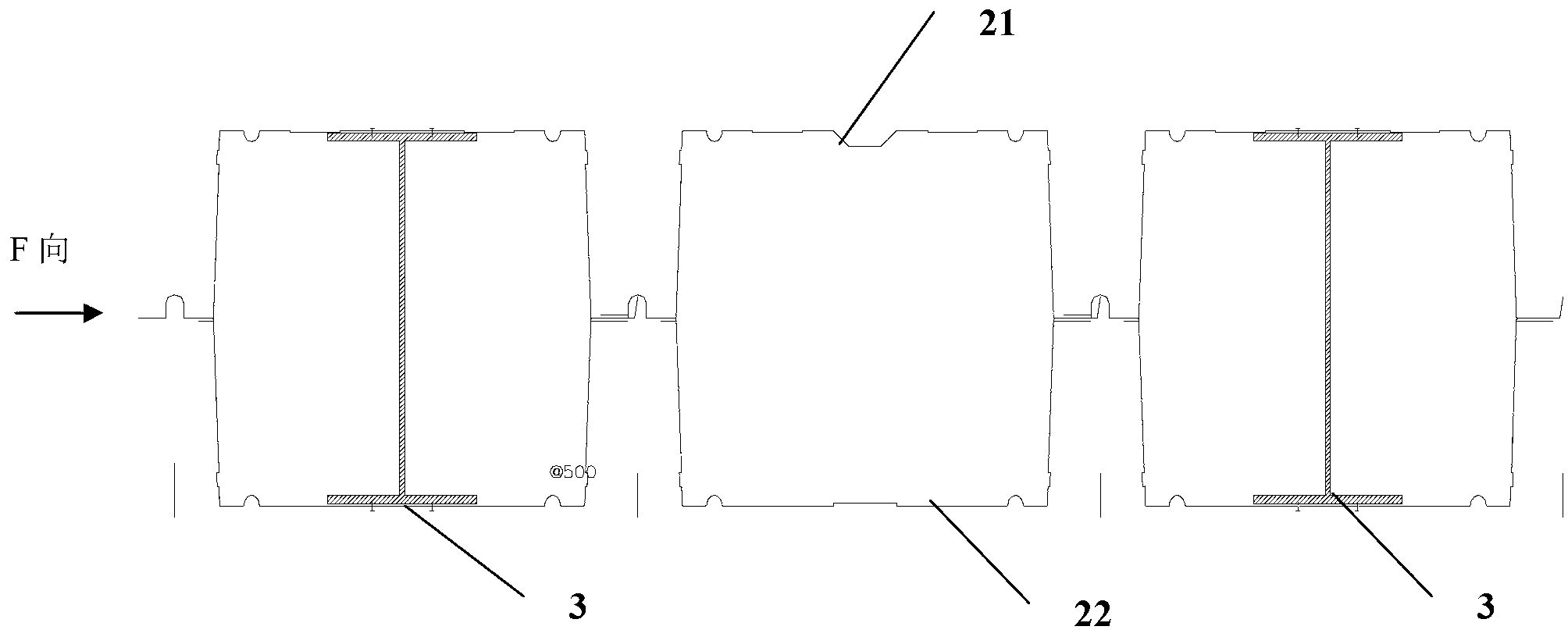

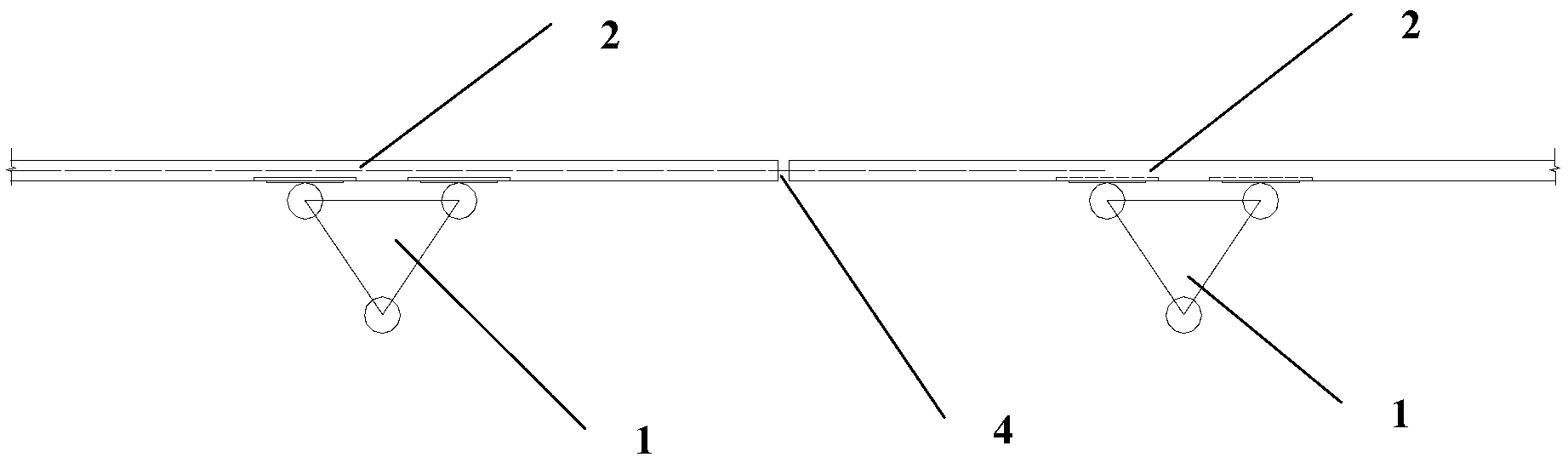

Embodiment 1

[0030] like Figures 5 to 10 As shown, it is a box-shaped profiled steel plate without dislocation expansion joints of the present invention, including rigid connecting strips and two transition connecting pieces, the rigid connecting strips are steel strips 5, and the transition connecting pieces are used to be respectively arranged on the two expansion joints 4. On the end faces of the side box-shaped profiled steel plates 6 and 7, one end of the steel bar 5 is fixed on one of the transition pieces, and this end is used as the fixed end, and the other end extends into the other side along the longitudinal direction of the box-shaped profiled steel plate as a free end. In the longitudinal chute on a transition piece, the free end of the steel bar 5 can move along the longitudinal chute to meet the longitudinal expansion and contraction of the box-shaped profiled steel plate, see Figure 7 , which can eliminate the vertical direction of the two box-shaped profiled steel plates...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that the H-shaped steel in the I-shaped state is not provided in the box-shaped profiled steel plates on both sides of the expansion joint, and the end faces of the box-shaped profiled steel plates on both sides of the expansion joint are provided with Sealing plate, the connecting side of the lug plate is connected to the sealing plate to realize the connection between the lug plate and the box-shaped profiled steel plate. At this time, the ear plate is perpendicular to both the sealing plate and the web of the H-beam as the transition piece.

Embodiment 3

[0037] The difference between this embodiment and Embodiment 1 is that H-shaped steel is provided on one of the box-shaped profiled steel plates on both sides of the expansion joint, and H-shaped steel is not provided on the other side of the box-shaped profiled steel plate. The end face of the box-shaped profiled steel plate is provided with a sealing plate, and the other side of the box-shaped profiled steel plate is provided with an H-shaped steel in an I-shaped state. The connection side of one ear plate is fixed on the sealing plate, and the connection of the other ear plate The side is butt-fixed with the web of the H-beam in the box-shaped profiled steel plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com