Moving load analog loading method and device for rail transit wheel axle

A technology for moving loads and rail transit, applied in tracks, track maintenance, roads, etc., can solve the problems of inability to achieve uniform movement of wheel and axle loads, size limitations, and difficulty in control, achieve reliable and convenient loading platforms, reduce size, and avoid long distances. The effect of the acceleration section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

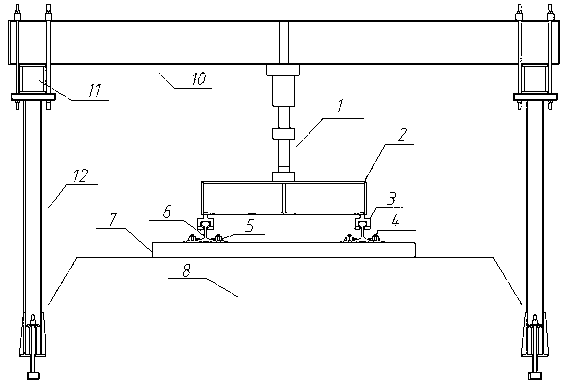

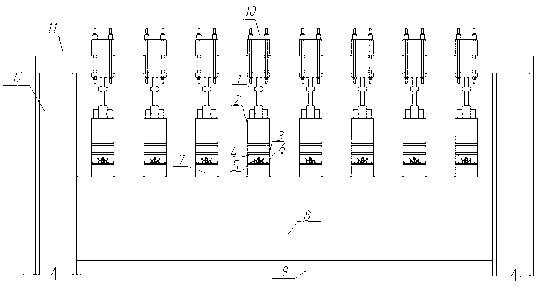

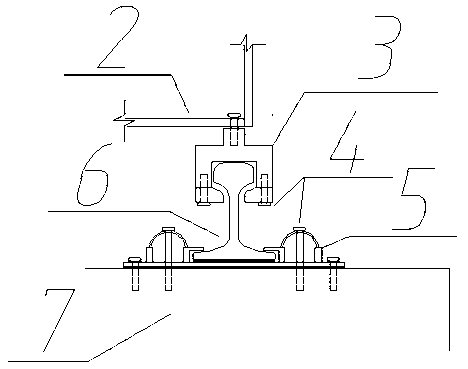

[0026] This example is in figure 1 with figure 2 The moving load simulation loading device of the rail transit axle shown in the figure is carried out on the ballasted track structure, the fastener system 5 is WJ-7 type, the rail 6 type is CHN60, the sleeper 7 is III type reinforced concrete sleeper, and the ballast bed 8 is divided into the surface layer of the ballast bed and the bottom layer of the ballast bed, the surface layer of the ballast bed is made of graded gravel, the bottom layer of the ballast bed is made of A / B filler, and the distance between each sleeper 7 along the track direction is , a total of 8 sleepers 7 are arranged, and 8 actuators 1 are arranged above the position of each sleeper 7. The bottom of each actuator 1 is connected at the mid-span of the distribution beam 2 with a high-strength bolt 4, and the bottom of the distribution beam 2 two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com