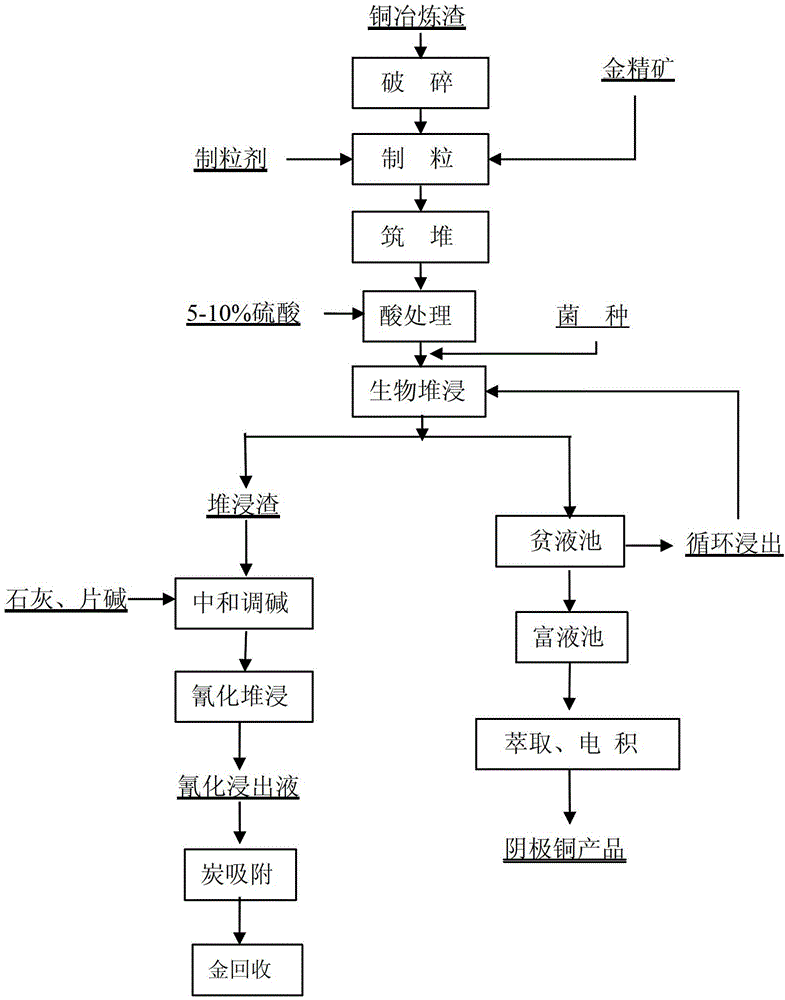

Process for comprehensively recovering gold and copper through combined biological dump leaching of refractory gold concentrate and copper melting slag

A technology of copper smelting slag and refractory gold, which is applied in the technical field of refractory gold concentrate and copper smelting slag combined bioheap leaching to comprehensively recover gold and copper, can solve the problems of low cost and poor permeability, and achieve low cost, Realize the effect of recycling and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

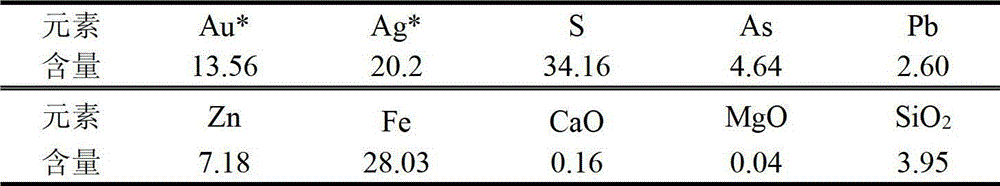

[0037] It comes from a low-grade refractory gold concentrate in Yunnan. With conventional cyanide leaching, the gold leaching rate is only about 10%, and the sodium cyanide consumption is more than 10kg / t ore. Gold in the gold concentrate is wrapped in pyrite in fine particles, and the chemical composition of the gold concentrate is shown in Table 1.

[0038] Table 1 Chemical composition of a low-grade refractory gold concentrate in Yunnan (%)

[0039]

[0040] *The unit is g.

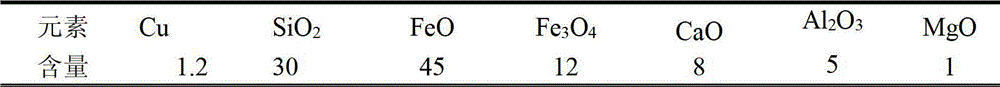

[0041] Table 2 Chemical composition of a flash slag (%)

[0042]

[0043] Take the copper flash slag described in Table 2, crush it to -40mm, mix it with the low-grade refractory gold concentrate in the above-mentioned Table 1 at a weight ratio of 6:1, and add cement accounting for 3% of the gold concentrate at the same time. Pellets with a particle size of 5-60 mm were made in a drum granulator. Send it to the stockyard with a dump truck to build a 3m-high ore heap, rinse the ore heap with sulf...

Embodiment 2

[0045] It comes from a low-grade refractory gold concentrate in Guizhou. With conventional cyanide leaching, the gold leaching rate is only about 15%, and the sodium cyanide consumption is more than 13kg / t ore. Gold in the gold concentrate is wrapped in pyrite in fine particles, and the chemical composition of the gold concentrate is shown in Table 3.

[0046] Table 3 Chemical composition of a low-grade refractory gold concentrate in Yunnan (%)

[0047]

[0048] *The unit is g / t.

[0049] Table 4 Chemical composition of a certain converter slag (%)

[0050]

[0051] Take the copper converter slag described in Table 4, crush it to -40mm, and mix it with the low-grade refractory gold concentrate in the above Table 3 at a weight ratio of 2:1, and add cement accounting for 8% of the gold concentrate at the same time. Pellets with a particle size of 5-60 mm are made in the granulator. Send it to the stockyard with a belt conveyor to build a 6m-high ore heap, rinse the ore ...

Embodiment 3

[0053] It comes from a low-grade refractory gold concentrate in Gansu. With conventional cyanide leaching, the gold leaching rate is only about 25%, and the sodium cyanide consumption is more than 12kg / t ore. Gold in the gold concentrate is wrapped in pyrite with fine particles, and the chemical composition of the gold concentrate is shown in Table 5.

[0054] Table 5 Chemical composition of a low-grade refractory gold concentrate in Yunnan (%)

[0055]

[0056] *The unit is g / t.

[0057] Table 6 Chemical composition of a Noranda process slag (%)

[0058]

[0059] Take the copper converter slag described in Table 6, crush it to -40mm, and mix it with the low-grade refractory gold concentrate in the above-mentioned Table 5 in a weight ratio of 4:1, and add cement accounting for 5% of the gold concentrate at the same time. Pellets with a particle size of 5-60 mm are made in the granulator. Send it to the stockyard with a belt conveyor to build a 5m-high ore heap, rinse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com