High-proportion pyrite cinder pellet sintering technique

A technology of pellet sintering and sulfuric acid slag, applied in the field of sintering process, can solve the problems such as the inability to meet the strict requirements of blast furnaces, the inability to apply high proportion of sulfuric acid slag, and the inability to achieve high proportion of sulfuric acid slag, etc. The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

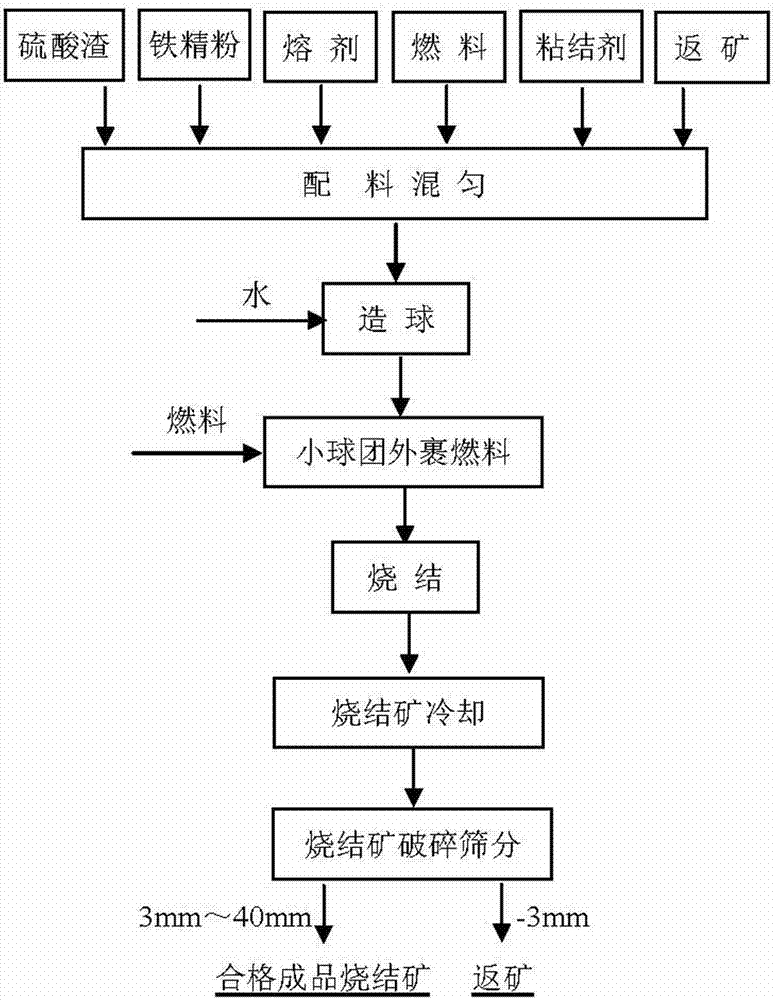

[0024] In this example, sulfuric acid slag from a place in Hunan is selected, with a sulfur content of 1.33%, and coke powder is used as fuel, of which 60% of the coke powder is used in step (1), and 40% of the coke powder is used in step (2), such as figure 1 Shown technological process specifically comprises the following steps:

[0025] (1) Preparation of pellets: Mix sulfuric acid slag and iron concentrate powder at a mass ratio of 3:7 to form the main ore, in which the particle size of sulfuric acid slag is less than 0.074mm, which is 85.3%; then the main ore, bentonite (binder) , coke powder, quicklime (flux) and returned ore plus water are mixed to form a mixed ore, wherein the quality of bentonite is 1.2% of the main ore quality, the quality of coke powder is 3.36% of the main ore quality, and the quality of quicklime is 5.5% of the main ore quality %, the quality of the returned ore is 15% of the main ore quality, and the amount of water added is 9.5% of the main ore ...

Embodiment 2

[0028] This embodiment selects sulfuric acid slag from a place in Anhui, and the sulfur content is 1.65%, such as figure 1 Shown technological process specifically comprises the following steps:

[0029] (1) Preparation of pellets: Mix sulfuric acid slag and iron concentrate powder according to the mass ratio of 3.5:6.5 to form the main ore, in which the particle size of sulfuric acid slag is less than 0.074mm, which is 89.5%; the main ore, bentonite (binder), Coke powder (fuel), quicklime (flux) and returned ore are mixed with water to form a mixed ore, in which the mass of bentonite is 1.5% of the mass of the main ore, the mass of coke powder is 4.4% of the mass of the main ore, and the mass of quicklime is the main mass of the ore 4.5%, the quality of the returned ore is 20% of the main ore quality, and the amount of water added is 8.7% of the main ore quality. The mixed ore was pelletized on a pelletizer, the pelletizing time was 13 minutes, the green ball drop strength w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com