A kind of preparation method of organosilicon oligomer for high-power LED encapsulation

A LED packaging and silicone technology, applied in the chemical field, can solve the problems of reducing polycondensation and cyclization reactions of phenyl monomers, cumbersome operations, and many steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

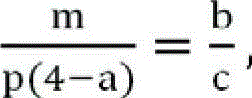

Method used

Image

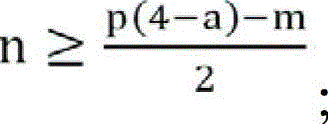

Examples

Embodiment 1

[0050] Into a 500mL three-necked flask equipped with a constant pressure funnel, a thermometer, a magnetic stirring and a distillation device, sequentially add 118.21g of hydrogen dimethylacetoxysilane, 200mL of toluene and 0.1g of trifluoromethanesulfonic acid, and raise the temperature to 50°C under stirring After 30 minutes, add 91.15 g of methylphenyldimethoxysilane dropwise to the reaction flask with a constant pressure funnel. After the dropwise addition, continue to stir and react for 1 hour, then raise the temperature to 80° C. and distill off the low boiling point liquid. After cooling to room temperature, wash with deionized water to neutrality, and rotary evaporate to obtain 130.07 g of a colorless transparent liquid with the structure shown in the following formula, with a yield of 96.2%.

[0051]

Embodiment 2

[0053]To a 500mL three-necked flask equipped with a constant pressure funnel, a thermometer, a magnetic stirring and a distillation device, sequentially add 144.25g of vinyldimethylacetoxysilane, 200mL of toluene and 0.1g of trifluoromethanesulfonic acid, and heat up to 50 °C, add 91.15g of methylphenyldimethoxysilane dropwise to the reaction flask with a constant pressure funnel over 30 minutes, after the dropwise addition, continue to stir for 1 hour, then raise the temperature to 80°C to distill off the low boiling point liquid. After cooling to room temperature, wash with deionized water until neutral, and rotary evaporate to obtain 153.89 g of a colorless transparent liquid with the structure shown in the following formula, with a yield of 95.4%.

[0054]

Embodiment 3

[0056] Into a 500mL three-neck flask equipped with a constant pressure funnel, thermometer, magnetic stirring and distillation device, add 141.85g of hydrogen dimethylacetoxysilane, 200mL of toluene and 0.1g of trifluoromethanesulfonic acid in sequence, and raise the temperature to 50°C under stirring After 30 minutes, 79.32 g of phenyltrimethoxysilane was added dropwise to the reaction flask with a constant pressure funnel. After the dropwise addition, the stirring reaction was continued for 1 hour, and the temperature was raised to 80° C. to distill off the low boiling point liquid. After cooling to room temperature, it was washed with deionized water to neutrality, and 128.45 g of a colorless liquid with the structure shown in the following formula was obtained by rotary evaporation, with a yield of 97.1%.

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com