Neutralized crystallization system and method of preparing caprolactam through caprolactam rearrangement solution

A caprolactam, crystallization system technology, applied in the separation/purification of lactam, chemical instruments and methods, ammonia compounds, etc., can solve the problems of unreasonable energy utilization, consumption of cooling and heat, heating, etc., to shorten the process flow and Equipment investment, heat and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

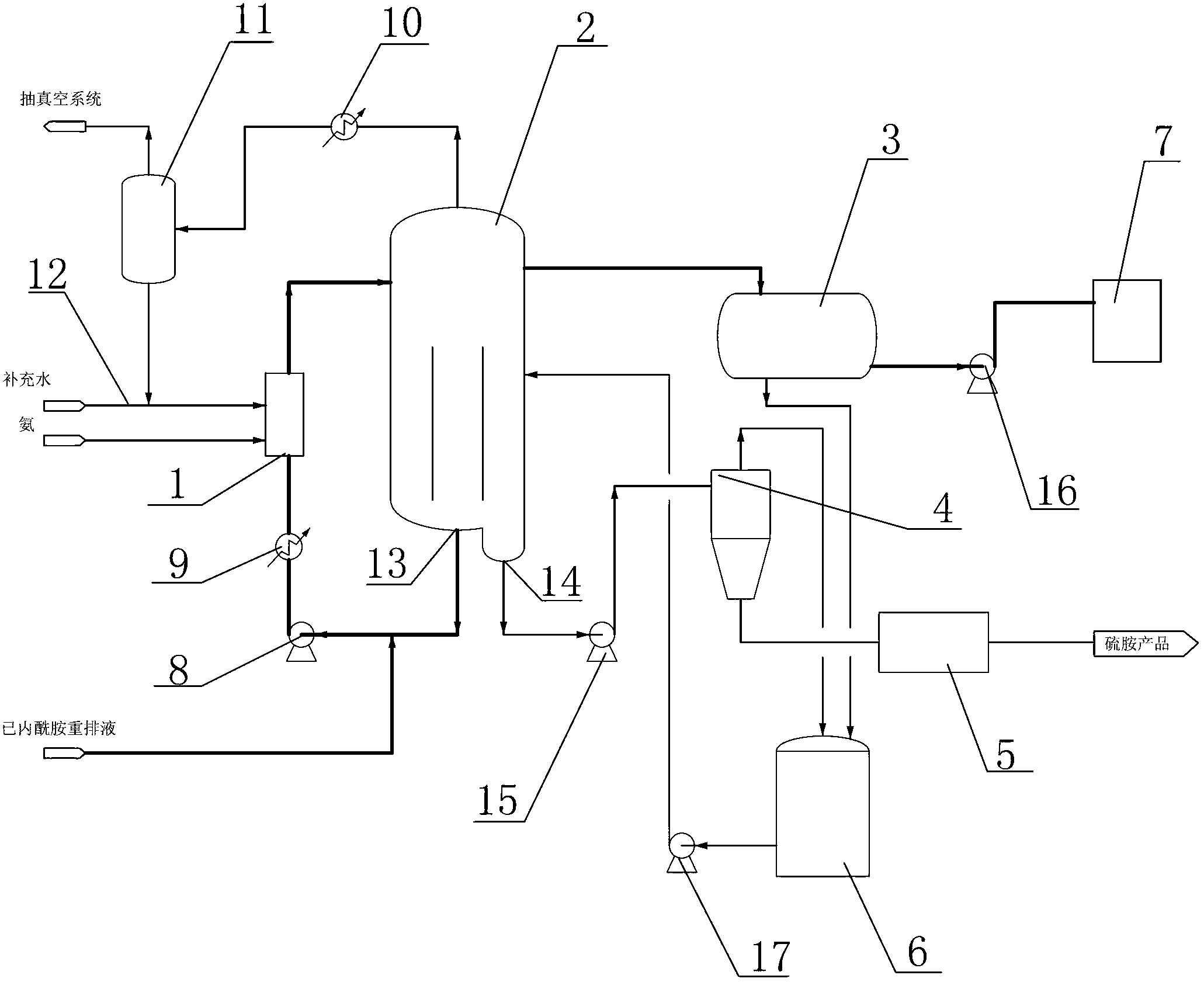

[0025] A kind of caprolactam rearrangement liquid of the present invention prepares the neutralization crystallization system of caprolactam, such as figure 1 Shown, comprise feed mixer 1, neutralization crystallization reactor 2, caprolactam oil stratifier 3, ammonium sulfate centrifuge 4, ammonium sulfate washing drier 5, ammonium sulfate mother liquor collection tank 6 and caprolactam collection tank 7, carry out The material mixer 1 is connected with the upper inlet of the neutralization crystallization reactor 2, the upper layer light organic phase outlet of the neutralization crystallization reactor 2 is connected with the inlet of the caprolactam oil stratifier 3, and the lower layer heavy organic phase of the neutralization crystallization reactor 2 Outlet 14 is connected with the inlet of ammonium sulfate centrifuge 4, and one end outlet of caprolactam oil stratifier 3 is connected with caprolactam collection tank 7, and the other end outlet is connected with ammonium ...

Embodiment 2

[0029] A kind of caprolactam rearrangement liquid of the present invention prepares the method for caprolactam, such as figure 1 As shown, it specifically includes the following steps:

[0030] (1) Send the caprolactam rearrangement liquid, ammonia and water into the feed mixer 1 with a mass ratio of 1:3:2.5 and mix them evenly, then send them to the neutralization crystallization reactor 2 for neutralization reaction, and the heat generated by the reaction makes the water Evaporate, reduced reaction temperature simultaneously, after neutralization reaction 5 minutes, the liquid in the neutralization crystallization reactor 2 is divided into the first light organic phase of the upper floor and the first heavy organic phase of the lower floor, wherein the operating pressure of the neutralization crystallization reactor 2 -0.095MPaG, operating temperature is 50°C;

[0031] (2) Extract the first light organic phase from the upper part of the neutralization crystallization reacto...

Embodiment 3

[0037] The same as Example 2, the difference is that in step (1), the caprolactam rearrangement liquid, ammonia and water are sent to the feed mixer 1 at a mass ratio of 1:3.5:2.75 and mixed evenly, and then sent to the neutralization crystallization reactor 2 The neutralization reaction occurred, and after 10 minutes of the neutralization reaction, the operating pressure of the neutralization crystallization reactor 2 was -0.07MPaG, and the operating temperature was 70°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com