Preparation method of organic rheology modifying agent for full-oil-based drilling fluid

A rheology modifier and drilling fluid technology, which is applied in the preparation of organic compounds, organic chemistry, and drilling compositions, etc., can solve the problems of low dynamic shear force, low viscosity, low shear rate, etc., and achieve improved Suspension and thixotropy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

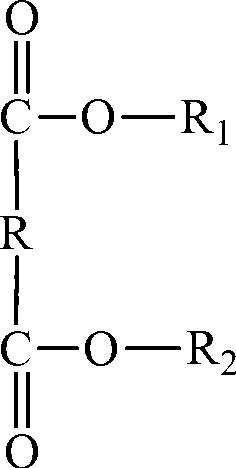

Method used

Image

Examples

Embodiment 1

[0029] Add 4 mol of dibasic fatty acid methyl ester with 36 carbon atoms, 4 mol of dihydroxypropyl Amine, heat up to 150°C with heat conduction oil, when the methanol collected in the receiver is about 2mol, lower the temperature to 120°C to reduce the volatilization of triethylenetetramine, then add 1mol of triethylenetetramine, then raise the temperature to 170°C, when The reaction was terminated when about 4 mol of methanol was collected in the receiver. After cooling down, add a mixed solvent of kerosene and propylene carbonate prepared at a mass ratio of 9:1, the mass ratio of the mixed solvent to the reaction product is 1:1, and stir evenly to obtain the product ORM-1.

Embodiment 2

[0031] Add 4 mol of dibasic fatty acid with 36 carbon atoms and 4 mol of propyl hydroxypropylamine in a four-port reactor with stirrer, thermometer, nitrogen device and Dean-Stark receiver, heat conduction oil to 150 ° C, When the water collected in the receiver is about 2 mol, the temperature is lowered to 120° C., 1 mol of triethylenetetramine is added, and then the temperature is raised to 170° C., and the reaction is terminated when the water collected in the receiver is about 4 mol. After cooling down, add a mixed solvent of 5# white oil and propylene carbonate prepared at a mass ratio of 9:1, the mass ratio of the mixed solvent to the reaction product is 1:1, stir evenly, and the product ORM-2 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com