Synthesis method of ionone-type spice intermediate products

A technology for the synthesis of ionones and synthetic methods, which is applied in the synthesis of ionone-based fragrance intermediates and the field of compound synthesis, which can solve the problems of low space-time yields and high catalyst costs, and achieve fewer reaction steps, high yields, and less pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

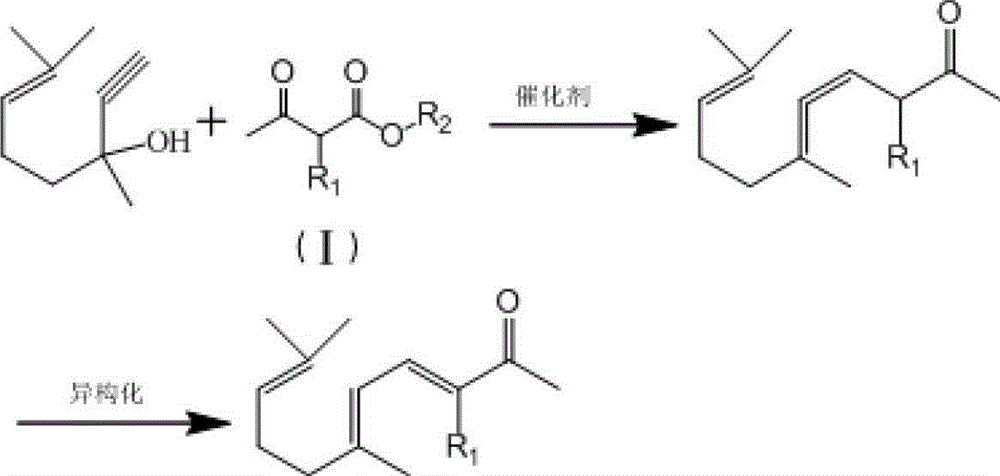

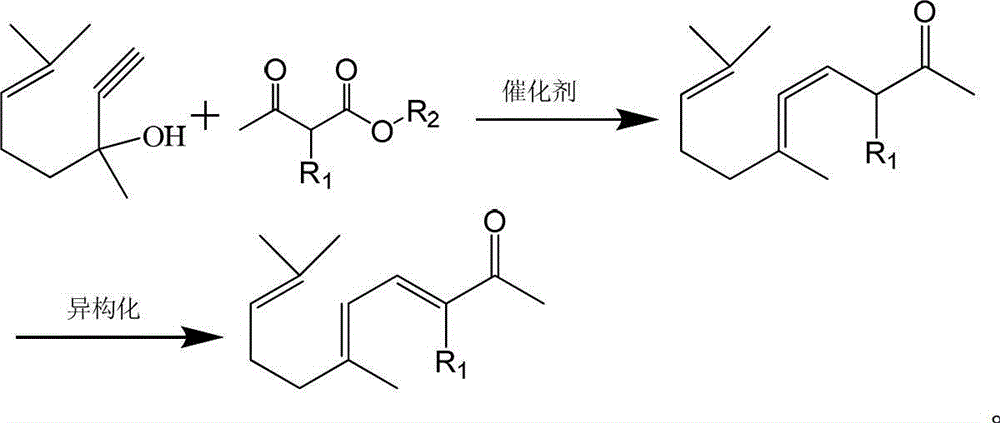

Method used

Image

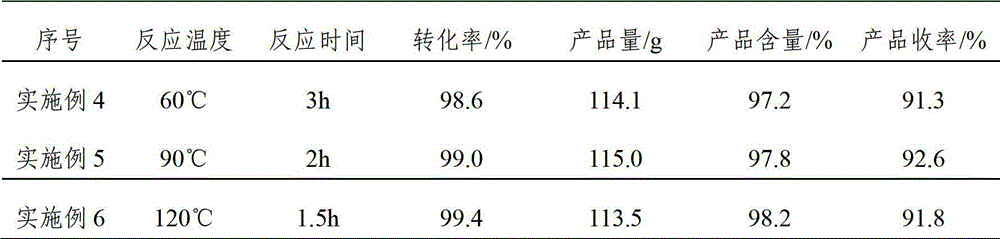

Examples

Embodiment 1

[0033] Put 100g (98.5% content) dehydrolinalool, 91.0g methyl acetoacetate and 4.0g aluminum isopropoxide into a 500ml pressure-resistant reaction flask, magnetically stir and heat to an internal temperature of 85°C with an oil bath to keep the reaction The pressure was 1.2 MPa to react for 2 hours, and the conversion rate of dehydrolinalool was 98.8% analyzed by gas chromatography. After the reaction is completed, fill with nitrogen to normal pressure, cool down to 15°C, add 50 ml of 0.5% sodium hydroxide methanol solution dropwise, and keep the temperature for 1.5 hours after dropping. After the isomerization is completed, add acetic acid to adjust the pH value between 6 and 7. The reaction solution was filtered on a column equipped with diatomaceous earth filter aid using methanol as a solvent, and the filtrate was rectified to obtain 97.5% (sum of cis-trans) pseudoionone product 117.3g. The yield of pseudoionone is about 93.1%

Embodiment 2

[0035] According to the method of Example 1, the only difference is that in this example, 91.0 g of methyl acetoacetate was changed to 83.5 g of methyl acetoacetate, and other conditions remained unchanged. The conversion rate of dehydrolinalool was 97.6%, and 114.5 g of pseudoionone product with a content of 98.1% was obtained. The yield of pseudoionone is about 92.5%

Embodiment 3

[0037] According to the method of Example 1, the only difference is that in this example, 91.0 g of methyl acetoacetate was changed to 98.5 g of methyl acetoacetate, and other conditions remained unchanged. The conversion rate of dehydrolinalool was 99.2%, and 114.3 g of pseudoionone product with a content of 97.8% was obtained. The yield of pseudoionone is about 92.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com