Gas-phase iodine crystallization method

A crystallization, gas phase technology, applied in the direction of iodine, iodine/hydrogen iodide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

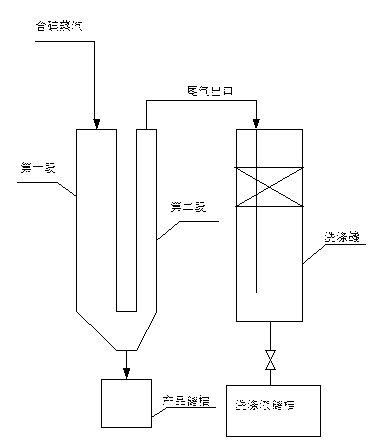

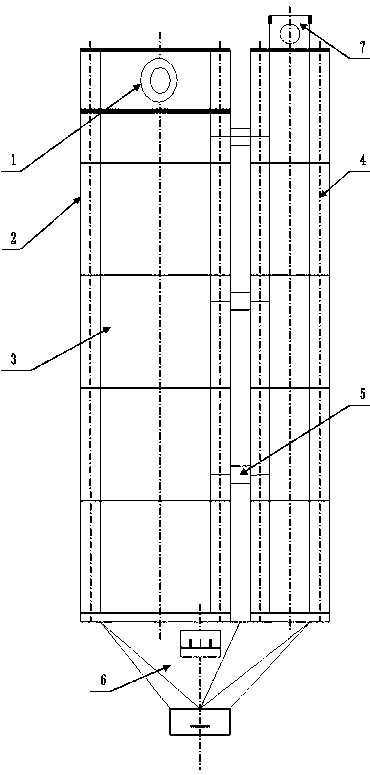

[0021] A method for gas-phase iodine crystallization. The crystallizer used in this method is composed of two sections, which are made into two cubes. The first section is 500mm×500mm×3800mm, and the second section is 250mm×250mm×3800mm. Thin film is used as heat exchange medium. Iodine vapor inlet 1 is arranged on the first section crystallizer 3, is the main crystallization area of iodine, and noncondensable gas outlet 7 is arranged on the second section crystallizer 4, is the secondary crystallization area of iodine; Two sections of crystallizers are fixed on one On the common cone bottom 6, the cone bottom 6 connects the two sections of crystallizers, the cone bottom 6 is a collector of iodine, and a container is arranged under the cone bottom 6; for strengthening stability, the two sections of crystallizers are connected by connecting brackets 6, The outside is connected with the shell bracket 2; the iodine vapor enters the first crystallizer 3 from the iodine vapor i...

Embodiment 2

[0025] A method for gas-phase iodine crystallization. The crystallizer used in this method is composed of two sections, which are made into two cubes. The first section is 500mm×500mm×3800mm, and the second section is 250mm×250mm×3800mm. Thin film is used as heat exchange medium. Iodine vapor inlet 1 is arranged on the first section crystallizer 3, is the main crystallization area of iodine, and noncondensable gas outlet 7 is arranged on the second section crystallizer 4, is the secondary crystallization area of iodine; Two sections of crystallizers are fixed on one On the common cone bottom 6, the cone bottom 6 connects the two sections of crystallizers, the cone bottom 6 is a collector of iodine, and a container is arranged under the cone bottom 6; for strengthening stability, the two sections of crystallizers are connected by connecting brackets 6, The outside is connected with the shell bracket 2; the iodine vapor enters the first crystallizer 3 from the iodine vapor i...

Embodiment 3

[0029] A method for gas-phase iodine crystallization. The crystallizer used in this method is composed of two sections, which are made into two triangles. The first section is an equilateral triangle with a base of 300 mm and a height of 3000 mm. The second section is a base with a base of 200 mm. The sides are triangular, the height is 3000mm, and the heat exchange medium is made of PTFE film. Iodine vapor inlet 1 is arranged on the first section crystallizer 3, is the main crystallization area of iodine, and noncondensable gas outlet 7 is arranged on the second section crystallizer 4, is the secondary crystallization area of iodine; Two sections of crystallizers are fixed on one On the common cone bottom 6, the cone bottom 6 connects the two sections of crystallizers, the cone bottom 6 is a collector of iodine, and a container is arranged under the cone bottom 6; for strengthening stability, the two sections of crystallizers are connected by connecting brackets 6, Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com