Multi-functional material conveying, distributing and hoisting equipment

A technology for multi-functional materials and lifting equipment, applied in cranes, building structures, processing of building materials, etc., can solve the problems of lifting equipment without material transportation, low function conversion efficiency, complex equipment structure, etc., and achieve simplification The structure of the lifting and luffing system and the overall structure of the equipment, the simple shape and structure, and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further explained below in conjunction with the drawings.

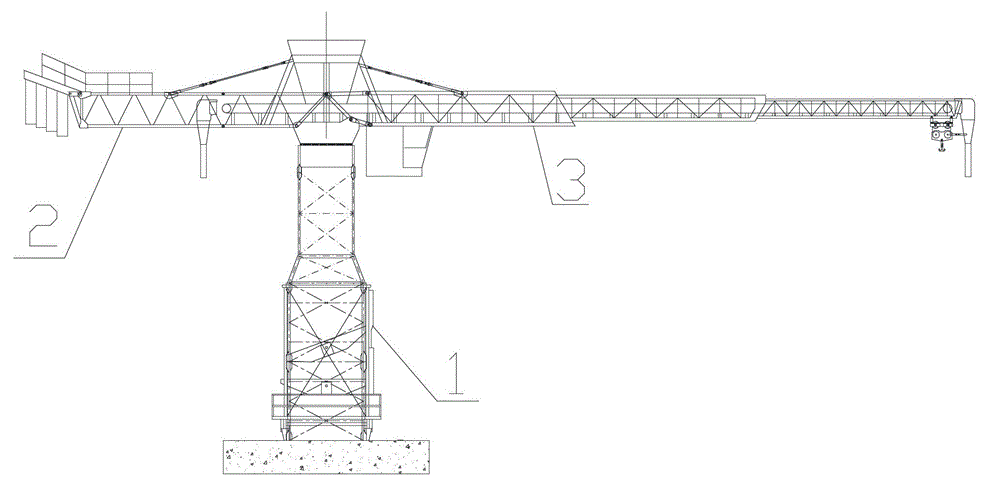

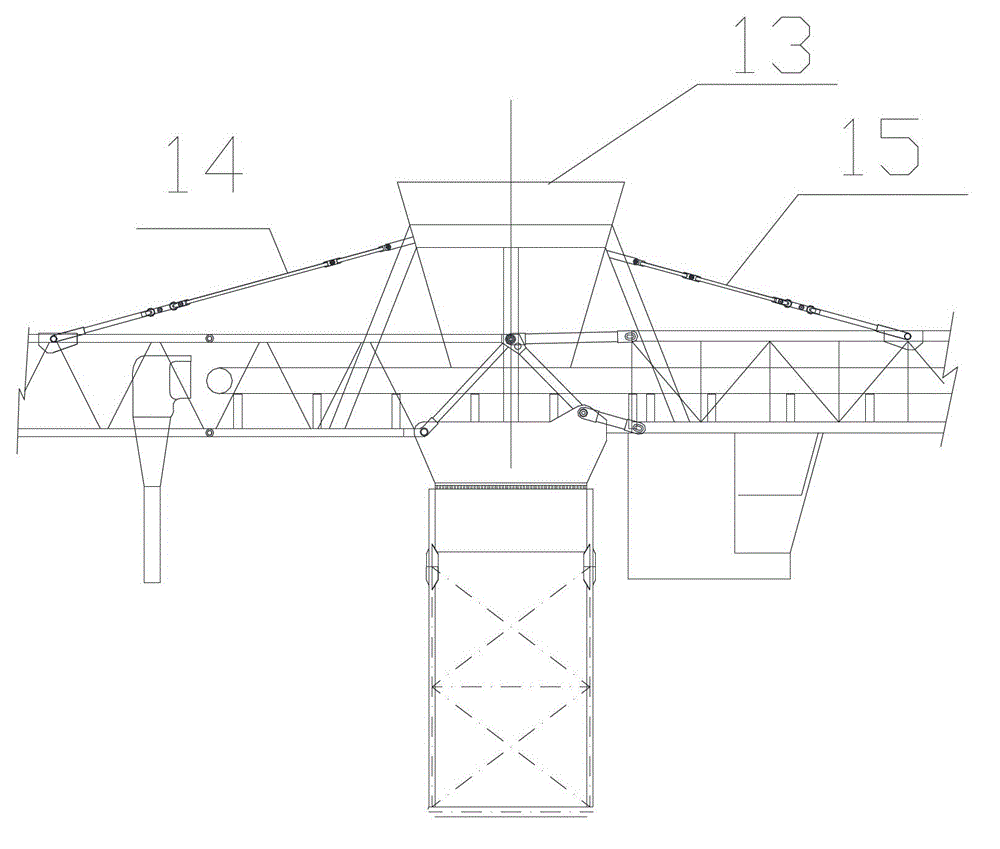

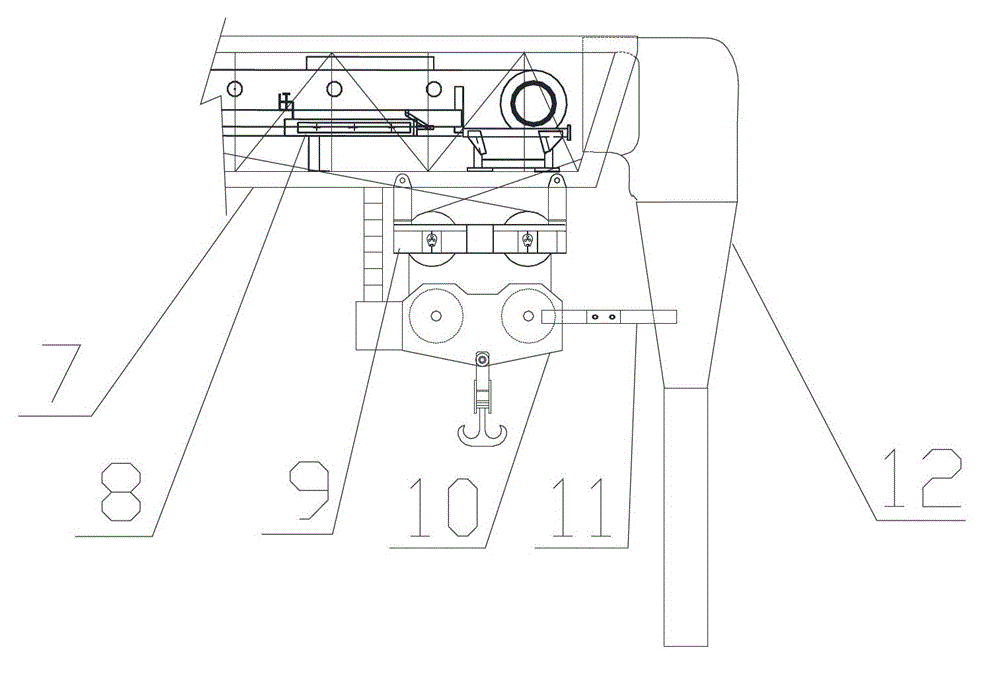

[0033] Such as figure 1 As shown, figure 1 It shows a structural schematic diagram of a non-pitch luffing type multifunctional material conveying, cloth and lifting equipment with a boom in an embodiment of the present invention. The multifunctional material conveying, cloth and lifting equipment in this embodiment is figure 1 The main parts marked in the middle are: tower body 1, balance arm 2, lifting arm 3. The tower body 1 is equipped with a rotating platform. The position of the rotating platform can be set at any position of the tower body under the condition of the boom non-pitch and luffing type. The rotating platform can be used to support multifunctional material conveying, cloth and lifting equipment. The rotation of the boom 3 and the balance arm 2. As a preferred embodiment, in this embodiment, the structure of the tower body 1 can be a truss type or a tower tube type, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com