Seat belt height self-adaptive adjustment method and device

A height adjustment device and self-adaptive adjustment technology, applied in the direction of the belt fixing device, etc., can solve the problems of inconvenient operation, unsafety, and increased driver's operation actions, so as to avoid manual adjustment, reduce operation actions, and enhance driving comfort Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

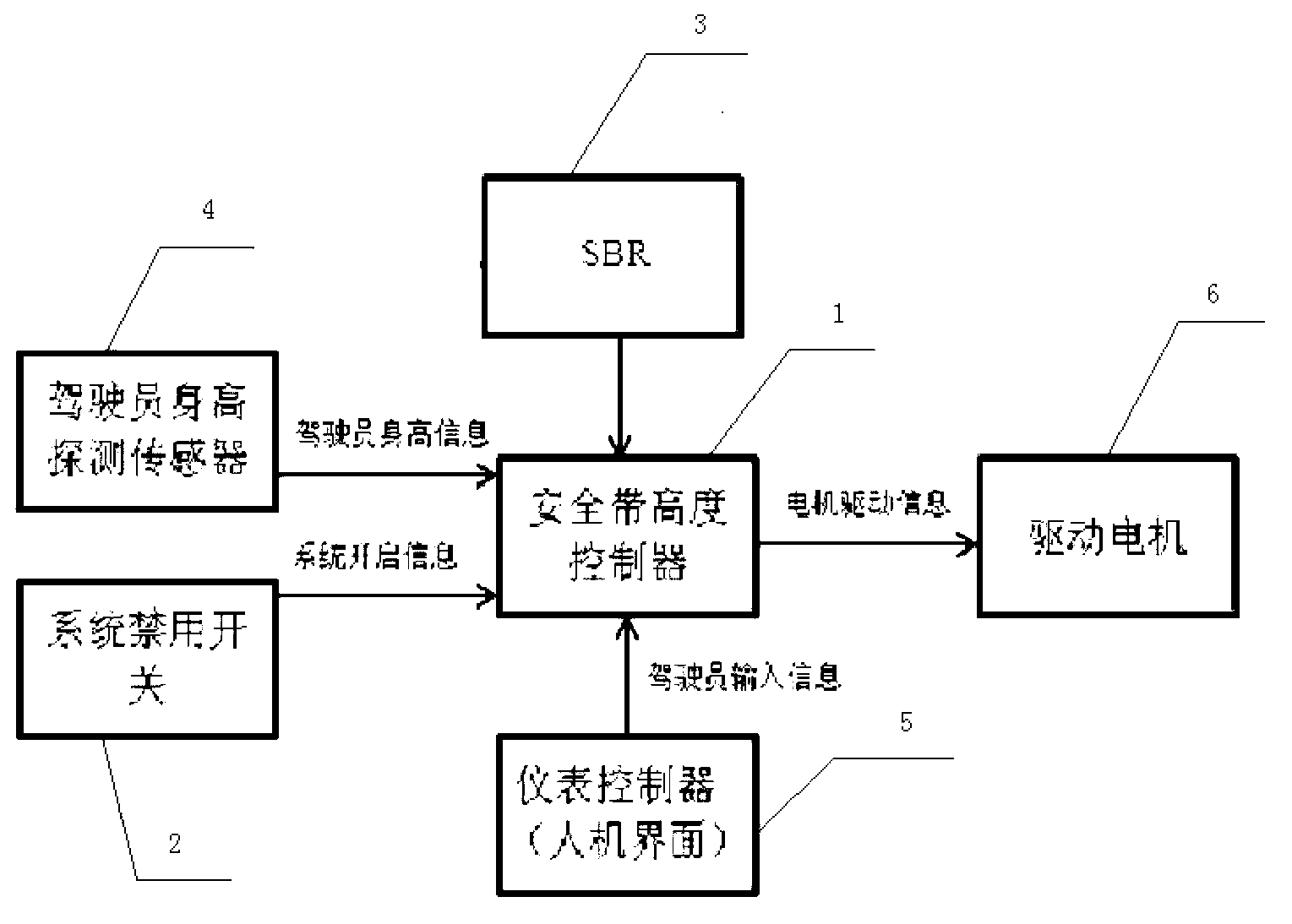

[0024] Such as figure 1 As shown, a safety belt height self-adaptive adjustment method comprises the following steps,

[0025] (1) After the engine is ignited, execute the system self-inspection. If the self-inspection finds a fault, notify the driver; if there is no fault in the self-inspection, go to step (2); way to alert the driver that the system is malfunctioning.

[0026] (2) Monitor whether the signal to start the seat belt height adaptive adjustment system is received, if the signal is not received, continue to step (2) monitoring; if the signal is received, go to step (3); when the engine has been ignited , when the vehicle is ready to start, the driver can either turn off the seat belt height adaptive adjustment system button and choose to manually adjust the seat belt height, or turn on the seat belt height adaptive adjustment system button to automatically adjust the seat belt height. Therefore, the system first Monitor whether the signal to start the seat belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com