Zerofriction inertia step scanister, control method, idem spot scanning double probe microscope

A step-scanning, frictionless technology, applied in the field of scanning dual-probe microscopes at the same point, can solve the problems of low positioning accuracy, interference of positioning accuracy, complicated control, etc., and achieve the effects of low cost, high positioning accuracy and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

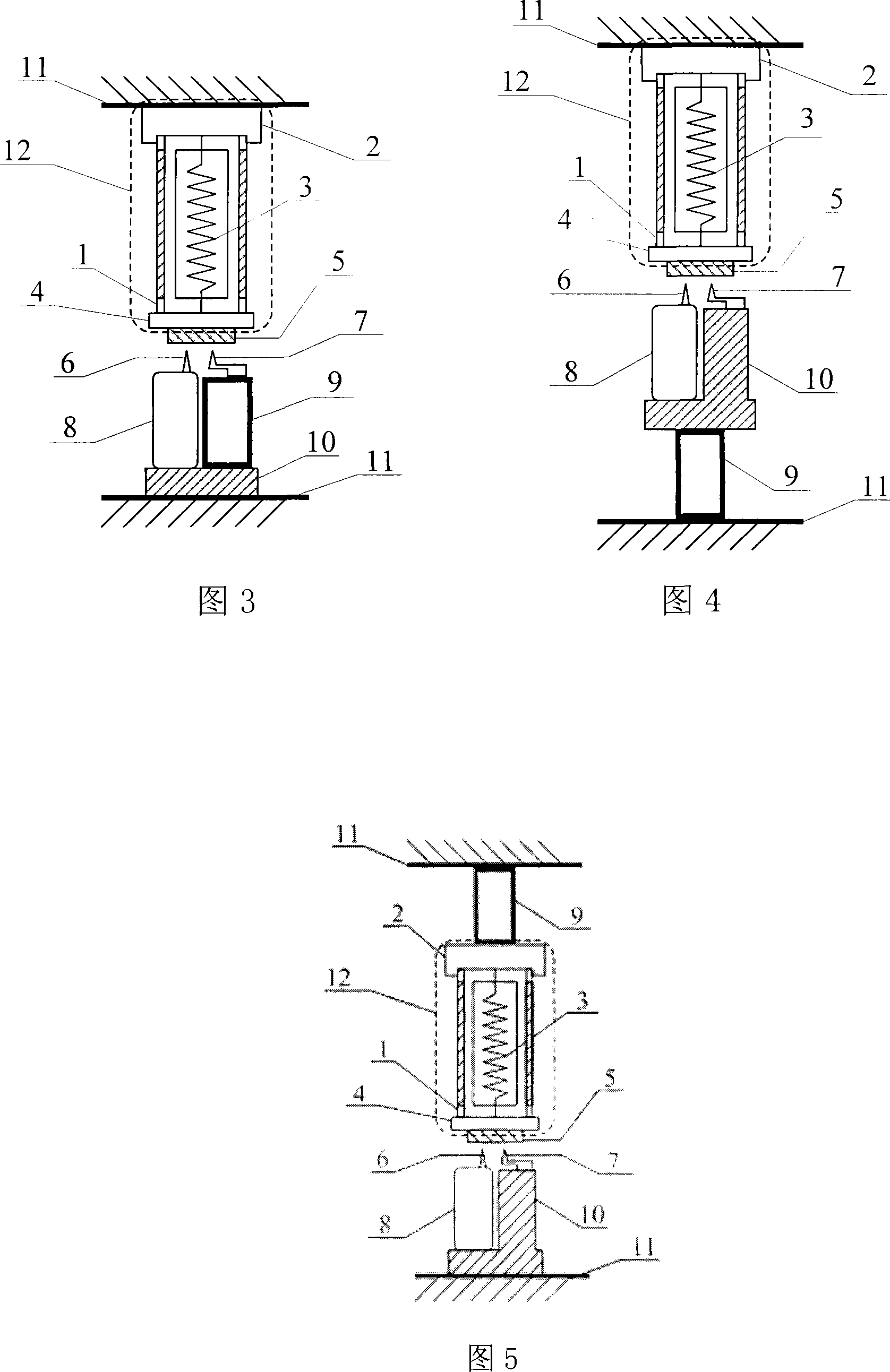

[0046] Embodiment 1: Frictionless inertial step scanner with built-in tensioner

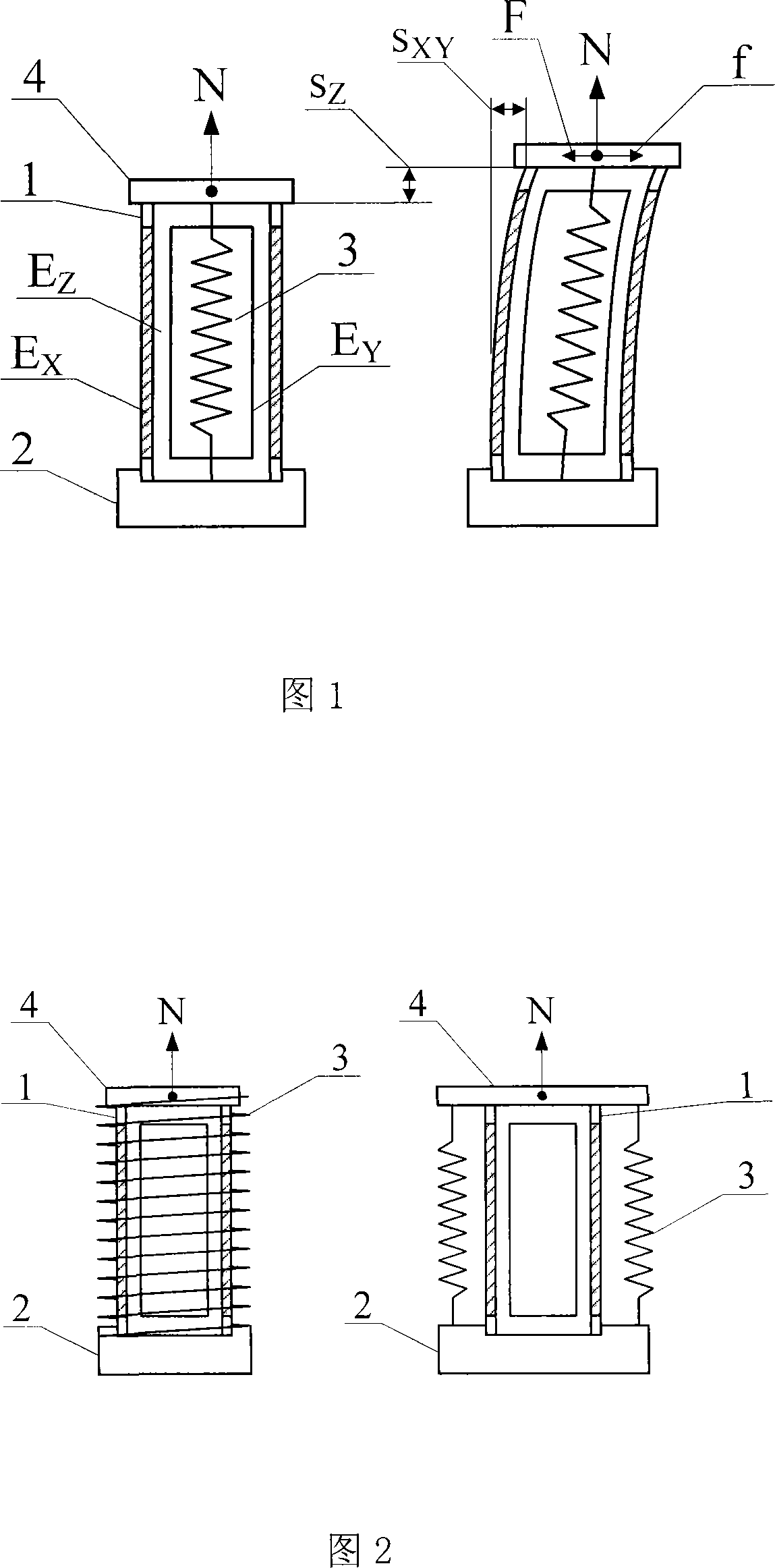

[0047] Referring to Fig. 1, one end of the XYZ piezoelectric scanning tube 1 is fixed on the base 2, the tensioner 3 pulls the pressing piece 4 to the base 2, and the scanning end of the XYZ piezoelectric scanning tube 1 supports the pressing piece 4 so that it will not be pulled Base 2. In this way, the effect of pressure N is generated between the pressing piece 4 and the scanning end of the XYZ piezoelectric scanning tube. The tensioner 3 can be a spring, a magnet, a hanging hammer, an elastic cord or a pressing piece itself. The tensioner 3 is placed inside the XYZ piezoelectric scanning tube 1 .

[0048] The frictionless inertial step scanner of this embodiment can work in the microscopic scanning and positioning mode, and can also work in the macroscopic large-scale stepping mode.

[0049] For microscopic scanning and positioning mode, the X electrode E of the XYZ piezoelectric scanning ...

Embodiment 2

[0051] Embodiment 2: Frictionless inertial step scanner with external tensioner

[0052] FIG. 1 shows the situation that the tensioner 3 is placed inside the XYZ piezoelectric scanning tube 1 . The position of the tensioner 3 can also be outside the XYZ piezoelectric scanning tube 1, as shown in FIG. 2 .

Embodiment 3

[0053] Example 3: Non-spring tensioner frictionless inertial step scanner

[0054] The setting of the tensioner is to pull the pressure piece to the base and interact with the scanning end of the XYZ piezoelectric scanning tube with pressure. Therefore, the tensioner can be located inside or outside the XYZ piezoelectric scanning tube, and its type can also be It is non-spring type, such as: elastic cord, magnet that attracts the pressing piece, a hanging hammer hanging under the pressing piece or the pressing piece itself (the pulling force that generates the pressure comes from the gravity of the pressing piece itself) and other devices that can generate the pressure .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com