Melamine plate for drilling PCB (Printed Circuit Board), and preparation method thereof

A technology of melamine board and melamine resin, applied in chemical instruments and methods, paper/cardboard layered products, synthetic resin layered products, etc., can solve problems such as easy moisture absorption and warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Taking urea-formaldehyde resin containing 0.3% curing agent as an example, add emulsifier (0.5% of the weight of urea-formaldehyde resin) and amino organic compound (0.08% of the weight of urea-formaldehyde resin) to analyze the different additives. The time required for the emulsified wax to demulsify in the urea-formaldehyde resin with the addition of curing agent. And take the urea-formaldehyde resin without adding any additives as a comparative example. Wherein, the emulsifier is emulsifier OP-10, and the amino compound is melamine. See Table 1 for specific results.

[0028] Table 1

[0029] Auxiliary do not add Emulsifier amino organic compound Emulsifiers and Amino Organic Compounds Time required for emulsified wax to demulsify / h 1.0 5.0 5.0 8.0

[0030] From the data analysis in Table 1, it can be seen that adding emulsifying wax or amino organic compound can prolong the demulsification time of emulsifying wax, among them, adding ...

Embodiment 2

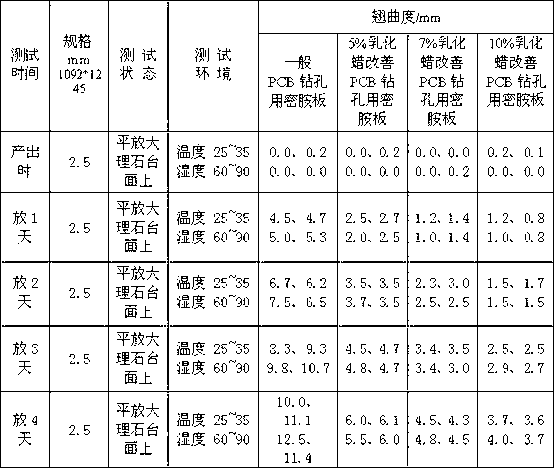

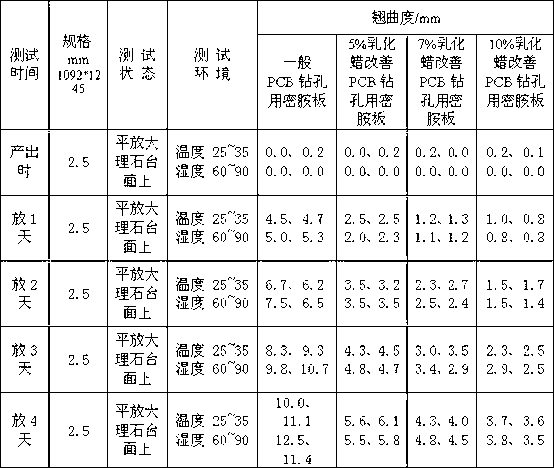

[0032] Add a curing agent to the urea-formaldehyde resin to adjust the curing time of the urea-formaldehyde resin; add amino organic compounds, emulsifiers and emulsifying wax in sequence (the addition method adopts the addition method of adding while stirring) to make a gluing solution for urea-formaldehyde resin; The paper base is immersed in the urea-formaldehyde resin sizing solution, and processed into a melamine board paper through the dipping process; the melamine board paper is attached to the melamine resin board, and processed through a high-temperature pressing process into a Melamine board for PCB drilling with moisture absorption effect. Wherein, the component ratio of the urea-formaldehyde resin sizing solution in the sample is shown in Table 2.

[0033] Table 2 Sizing resin composition ratio

[0034] test group Urea-formaldehyde resin / g Curing agent / g Emulsifying wax / g Amino organic compound / g Emulsifier / g 1 100 0.3 5 0.08g melamine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com