Slender axle multi-station different drilling fixture

A drilling jig and slender shaft technology, which is applied in the field of slender shaft multi-station anisotropic drilling jigs, can solve the problems of increasing the labor intensity of operators, increasing the cost of tooling, time-consuming and laborious, and reducing labor intensity. ,Easy to operate and reduce the number of replacements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

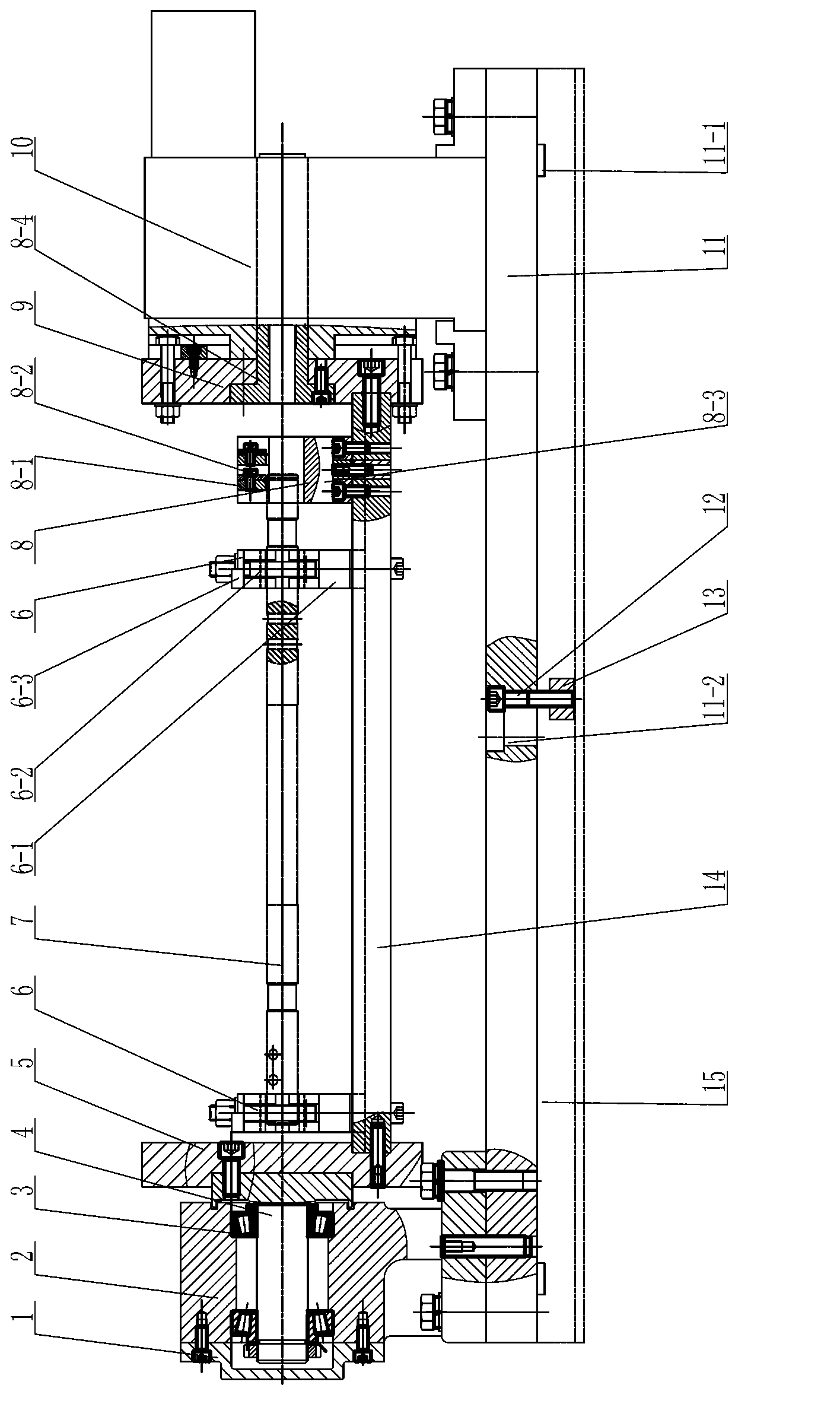

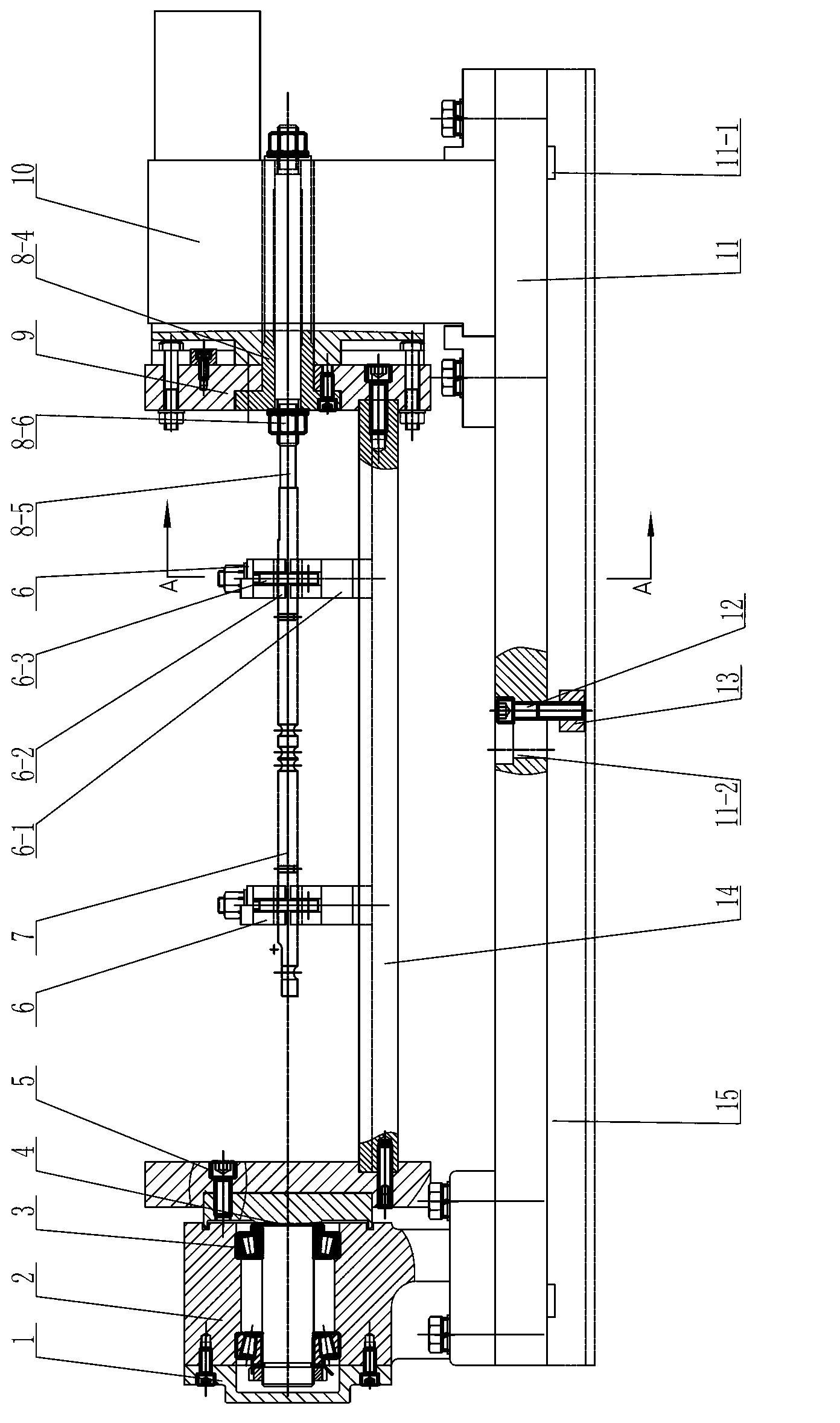

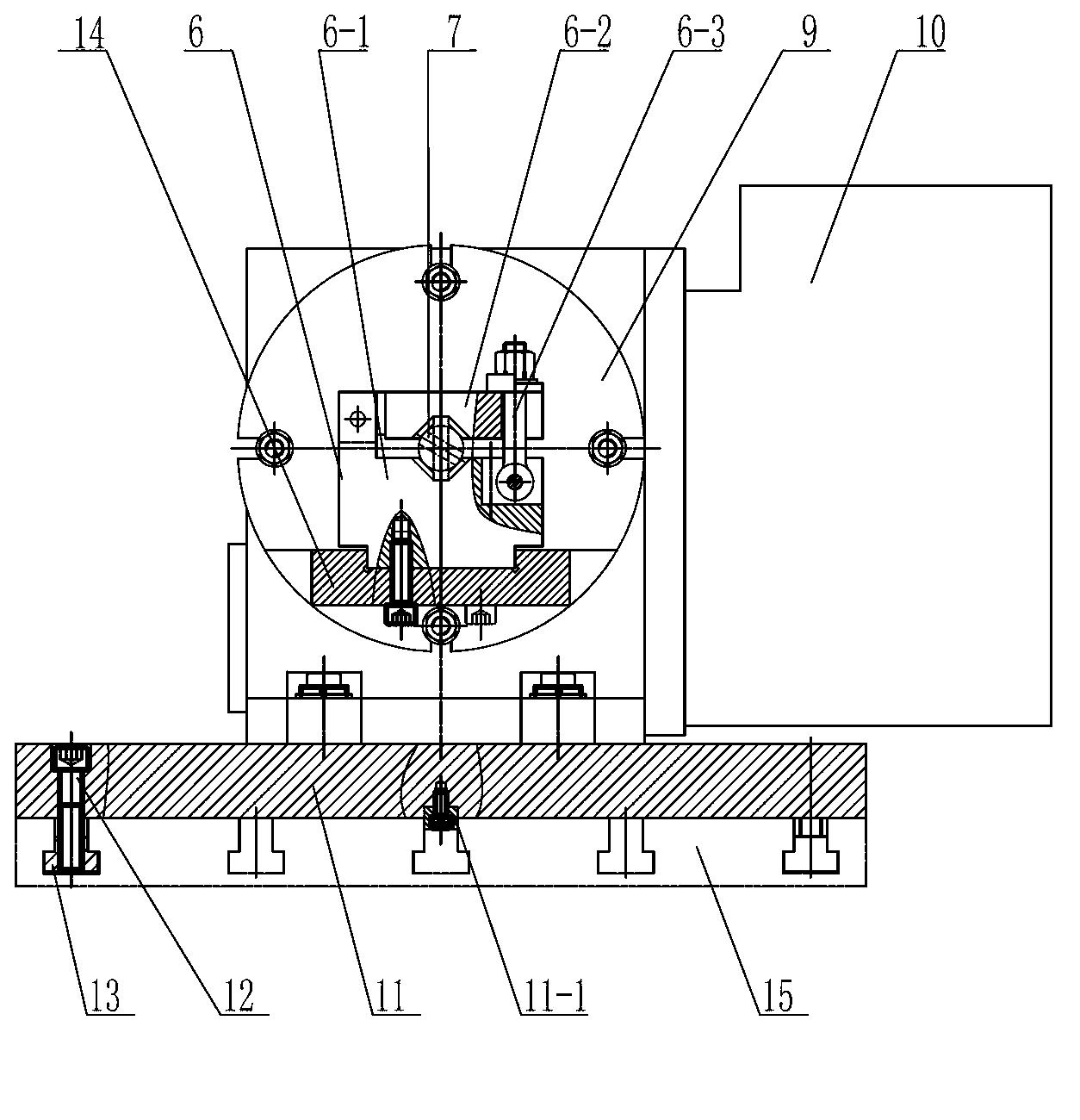

[0011] See Figure 1-3 As shown, the slender shaft type multi-station different-direction drilling jig of the present invention includes a base plate 11 and a rotary support 2 and a numerically controlled indexing plate 10 respectively installed on both sides of the base plate 11 with the same central axis, and the base plate 11 is provided with There is a positioning column 11-1 positioned with the workbench 15 and a connecting piece connected with the workbench 15, and the bottom plate 11 is installed on the workbench 15 of the machining center. See Figure 1-3 As shown, the positioning column 11-1 of the present invention is installed on the base plate 11 by screws, and the positioning column 11-1 matches the T-shaped groove on the workbench 15, and the base plate 11 is positioned on the workbench 15 by the positioning column 11-1 , and the connecting piece includes a bolt 12 and a T-shaped nut 13 connected to the lower part of the bolt 12, the T-shaped nut 13 is matched w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com