A self-aligning fixture for clamping precision forgings

A precision forging and clamping technology, applied in the field of self-aligning fixtures for clamping precision forgings, can solve the problems of low cost of use, poor clamping of forgings, poor precision, etc. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention can be explained in more detail by the following examples, and the present invention is not limited to the following examples;

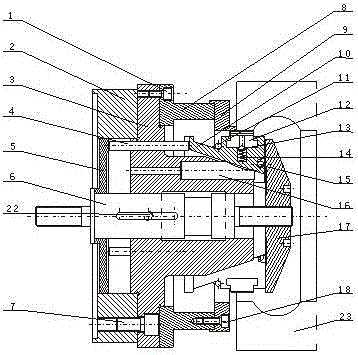

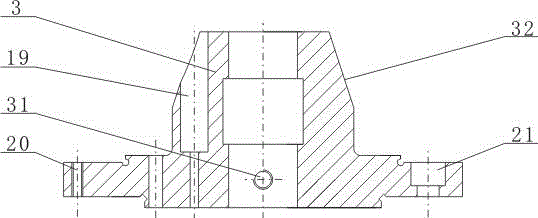

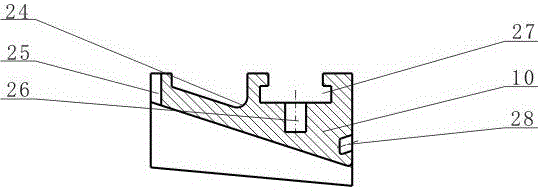

[0032] combined with Figure 1~4 The self-aligning fixture for clamping precision forgings includes a transition plate 2, a frame body 3, a transmission mechanism and a clamping mechanism. A plurality of through thread holes 20 and stepped holes 21 are arranged. The thread holes 20 and the stepped holes 21 are arranged alternately. A plurality of through pin holes are arranged at the end surface near the annular boss. On the outside of the seat frame body 3 There is an anti-rotation pin installation hole 31 penetrating to the middle inner hole on the edge surface, wherein one end of the frame body 3 is connected to the transition plate 2 by at least two fastening screws B7, and the other end of the frame body 3 is connected by the fastening screw A1 Connect the positioning ring base 8, the end of the positioning ring bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com