Follow-up clamping device

A technology of clamping device and clamping mechanism, which is applied in the direction of positioning device, clamping, supporting, etc., can solve the problems of deviation of the center of gravity of pipe fittings, clamping pipe fittings, and looseness of the clamping head, etc., and achieves simple and reliable adjustment, reasonable structure, and guarantee The effect of process precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

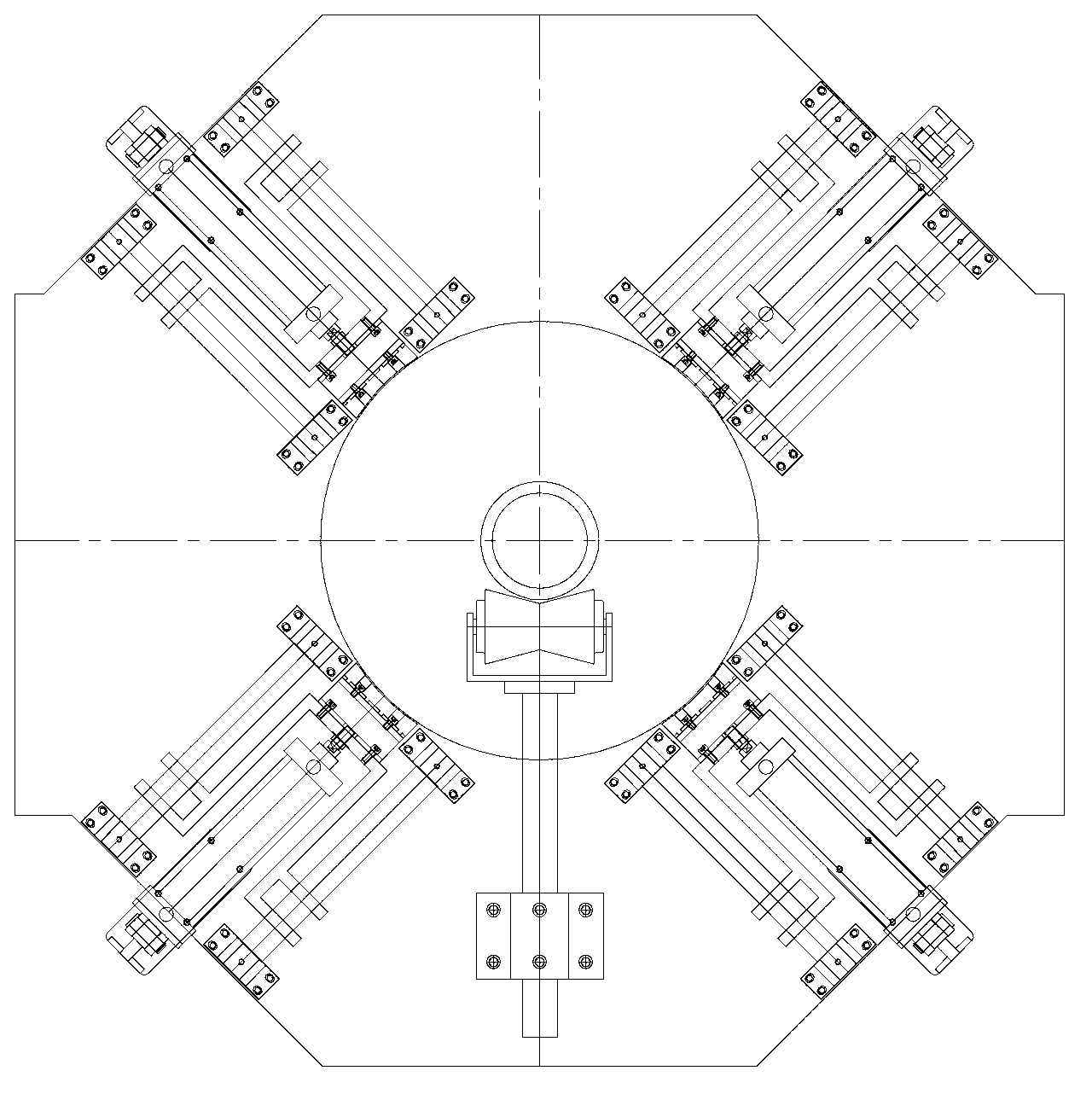

Image

Examples

Embodiment Construction

[0022] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

[0023] The "left and right" direction in this manual refers to the attached image 3 and attached Figure 4 The left and right direction, "vertical" direction in the image 3 and attached Figure 4 The up and down direction and "horizontal" direction in the image 3 and attached Figure 4 in the left-right direction.

[0024] as attached image 3 , attached Figure 4 and attached Figure 5 As shown, the follow-up clamping device of the present invention is used to clamp and fix the pipe fitting 19 so as to perform other operations on the pipe fitting 19. The device includes a first supporting body 1, which is slidably arranged on the first supporting body 1 The second supporting body 2, the clamping mechanism fixedly arranged on the first supporting body 1 and the supporting mechanism which can be lifted and lowered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com