Preparation method and preparation device for enhanced hollow fiber composite film

A fiber composite and reinforced technology, which is applied in the field of preparation of reinforced hollow fiber composite membranes, can solve the problems of high manufacturing cost, complex process and high density of supporting tubes, etc. Strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

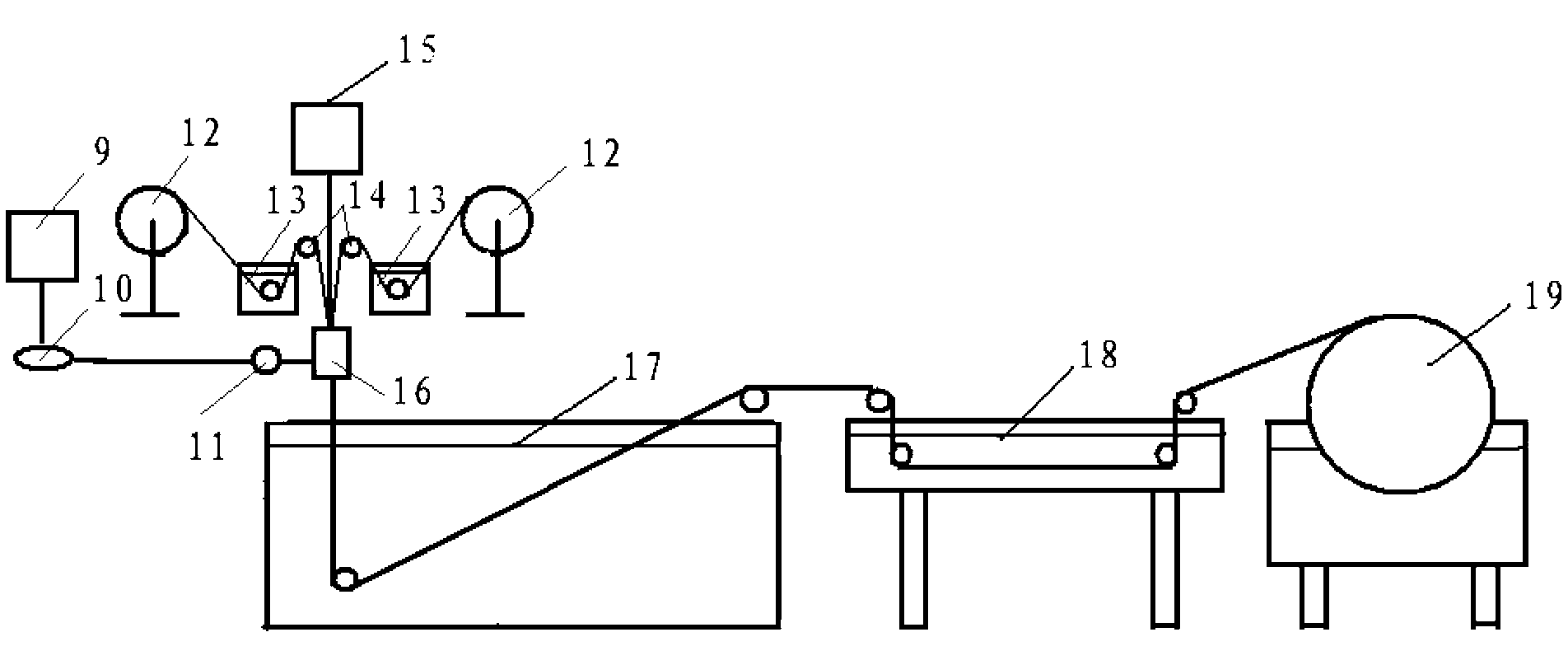

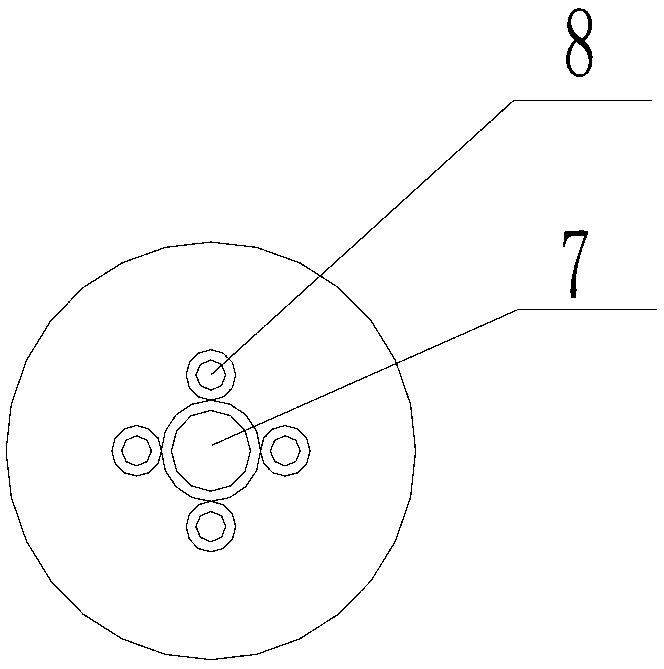

[0036] A fiber composite reinforced hollow fiber composite membrane, which is mixed according to the weight ratio of polyvinylidene fluoride resin, polyvinyl chloride resin, dimethylformamide, polyvinylpyrrolidone and polyethylene glycol in a weight ratio of 6:14:70:1:9 The ingredients are stirred at about 65°C to form a homogeneous solution, and then degassed for 6 hours with a negative pressure of 0.1MPa. The casting solution made after degassing is placed in the spinning kettle 9, and then, the fibers are prepared according to the following method Composite reinforced hollow fiber composite membrane:

[0037] (1) Lead out two polyester fibers from the wire reel 12, and then carry out pretreatment through the solvent tank 13, so that the oil in the polyester fibers can be washed, so that the fine fibers can be dispersed;

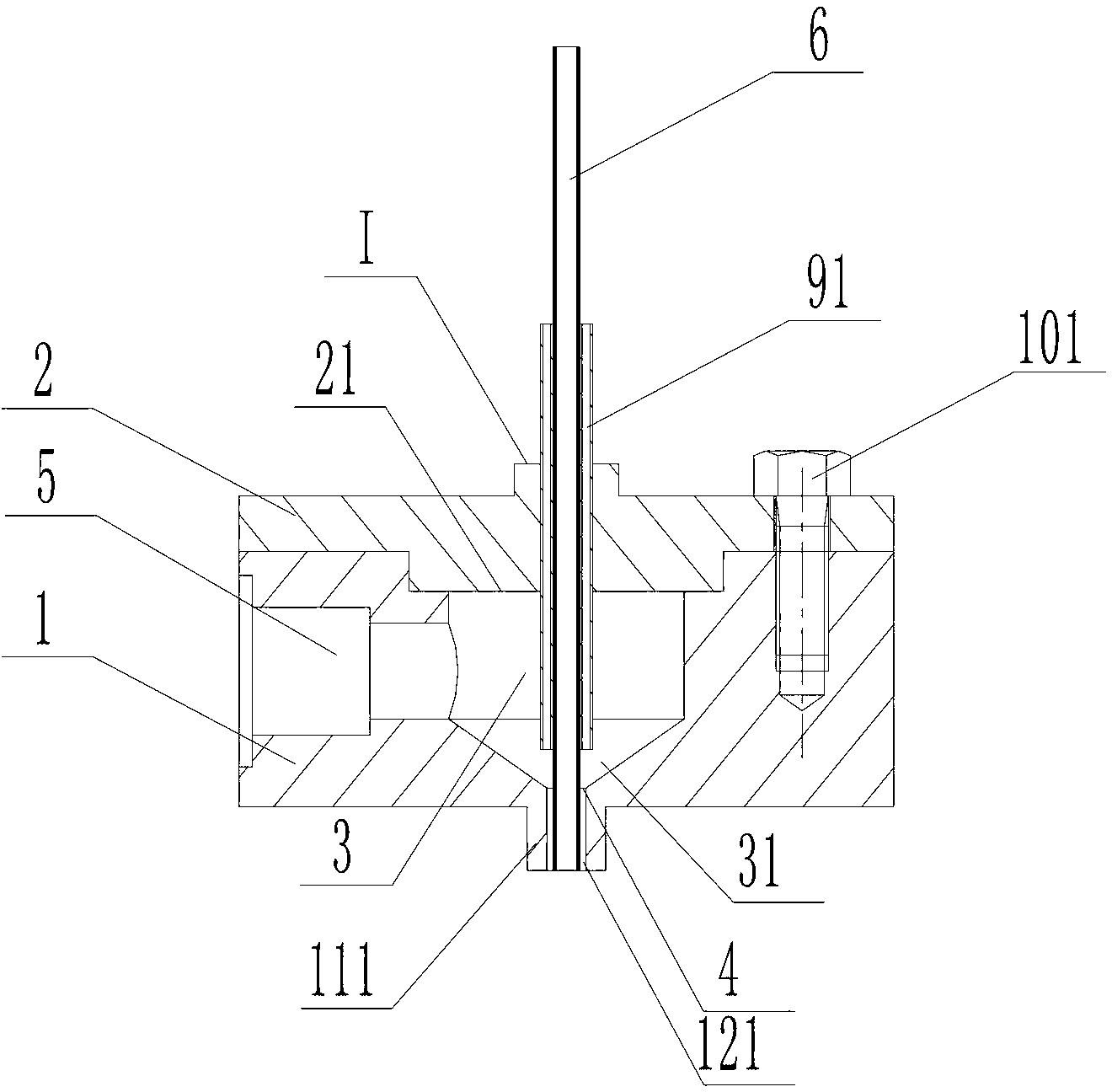

[0038] (2) Pass the polyester fiber through the tension control device 14, and then pass the polyester fiber through the corresponding needle tube on the ...

Embodiment 2

[0056] A fiber composite reinforced hollow fiber composite membrane, which is mixed according to the weight ratio of polyvinylidene fluoride resin, polyvinyl chloride resin, dimethylformamide, polyvinylpyrrolidone and polyethylene glycol at a weight ratio of 1:16:70:12:1 The ingredients were stirred at 65°C to form a homogeneous solution, and then degassed for 6 hours with a negative pressure of 0.1MPa. The casting solution made after degassing was placed in the spinning kettle 9, and then, the fiber composite reinforcement was prepared according to the following method Type hollow fiber composite membrane:

[0057] (1) Lead out 4 aramid fibers from the coil 12, and then pre-treat them through the solvent tank 13 to clean the oil in the aramid fibers;

[0058] (2) passing the aramid fiber through the tension control device 14, and then passing the aramid fiber through the corresponding needle tube on the spinneret 16;

[0059] (3) Then the aramid fiber enters the 1# gel tank ...

Embodiment 3

[0069] A fiber composite reinforced hollow fiber composite membrane, according to the weight ratio of polyvinylidene fluoride resin, polyethersulfone, dimethylformamide, polyvinylpyrrolidone, polyethylene glycol and lithium chloride 16:3:70:2: Mix ingredients at 8:1, stir at 70°C to form a homogeneous solution, then use a negative pressure of 0.1MPa to defoam for 12 hours, and place the casting solution after defoaming in the spinning kettle 9, and then follow the following method Preparation of fiber composite reinforced hollow fiber composite membrane:

[0070] (1) Lead out 3 polyester fibers from the wire reel 12, and then pre-treat them through the solvent tank 13 to make the oil in the polyester fibers fine and clear, so that the fine fibers can be dispersed;

[0071] (2) Pass the polyester fiber through the tension control device 14, and then pass the aramid fiber through the corresponding needle tube on the spinneret 16;

[0072] (3) Then, the polyester fiber enters th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Pure water flux | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com