Protective automatic filter press plate dragging mechanism

An automatic plate pulling and filter press technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of oily contaminated materials and external environment, track pollution, chain lubrication difficulties, etc., to achieve civilized management, Reduce the number of refills and facilitate cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The structure of the automatic plate pulling mechanism of the protective filter press provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

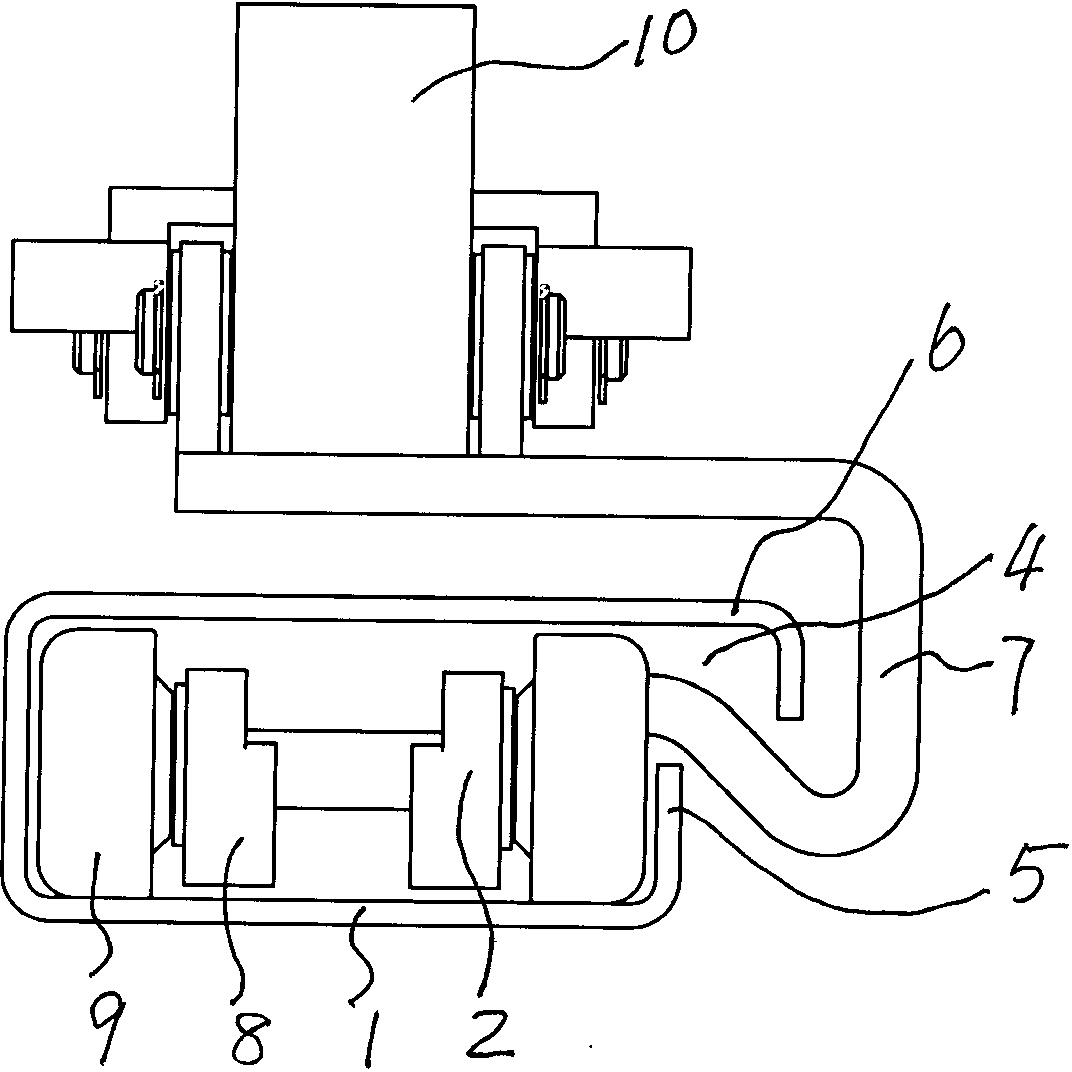

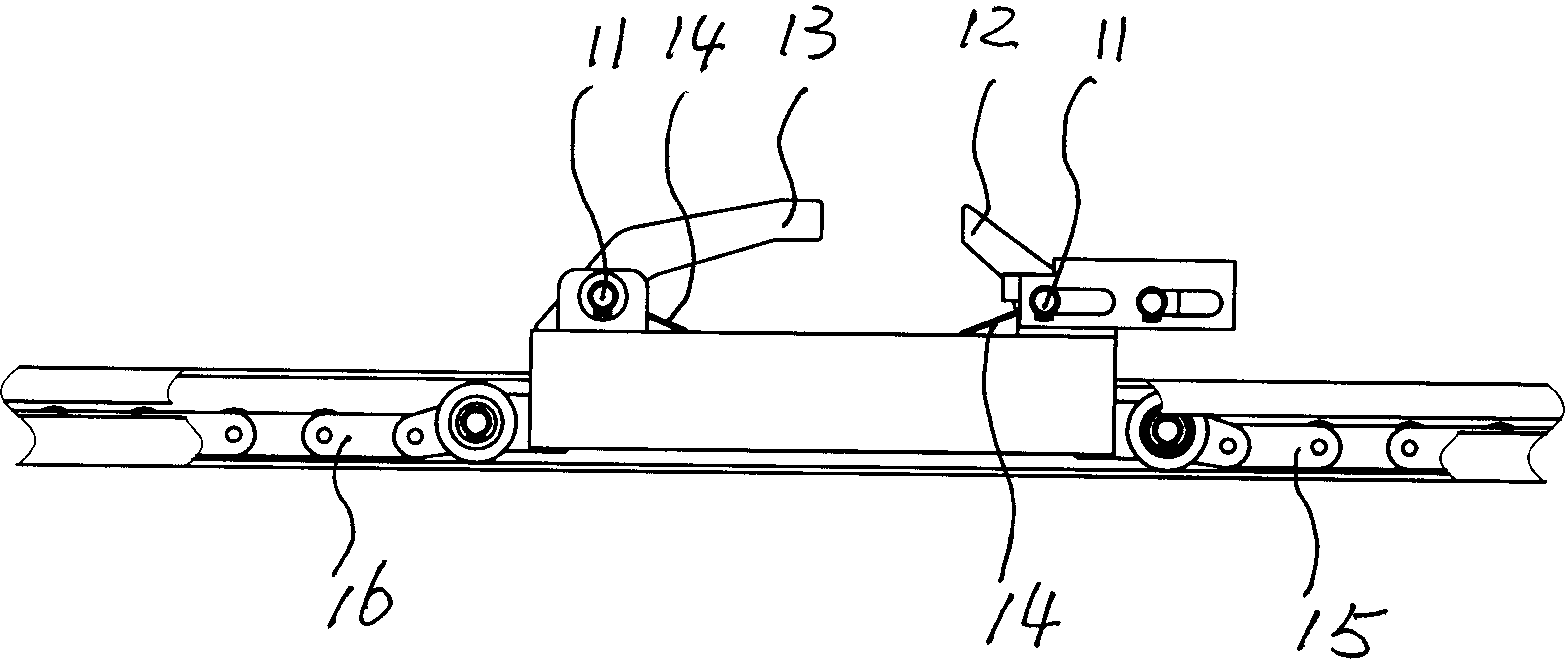

[0016] like figure 1 As shown, it is a structural schematic diagram of the automatic plate pulling mechanism of the protective filter press provided by the present invention. Its structure includes a trolley track 1 with a rectangular structure in cross section and a trolley 2 that can slide in the track; wherein, an opening 4 is provided on the right side wall 3 constituting the track, and the upper edge of the opening 6 protrudes from the lower edge 5 and forms a curved shape downward, and the connecting arm 7 connected with the sliding trolley stretches out from the opening, obliquely downward, then extends upward and then to the left, and is connected with the trolley manipulator 10 installed above the two wheels Connect and fix; Wherein, the structure of ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com