Material recovery device of mochi machine

The technology of mochi machine and residual material is applied in the field of mochi machine recycling residual material device, which can solve the problems of material pollution, affecting the normal operation of equipment, affecting the braking efficiency of equipment, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

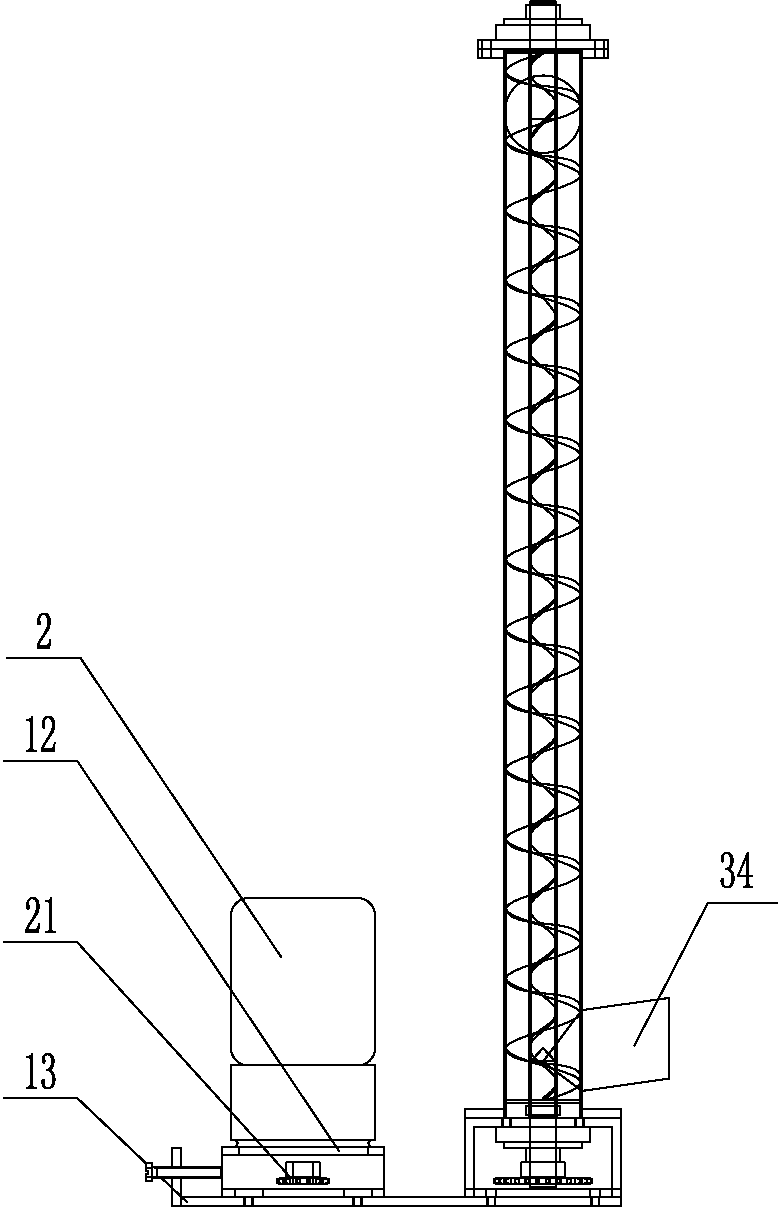

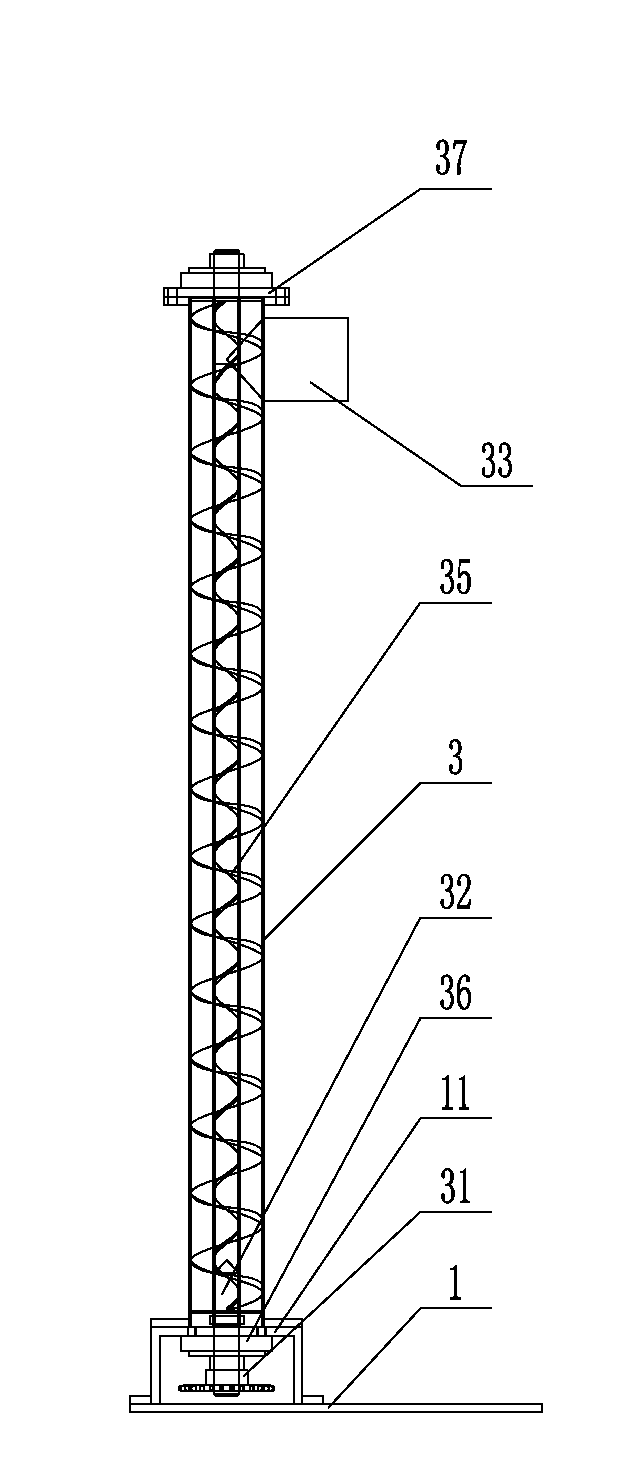

[0012] In order to make the purpose of the present invention, technical solutions and advantages clearer, in conjunction with the following drawings, it will be further described in detail, refer to figure 1 and figure 2 .

[0013] Mochi machine reclaims surplus material device, comprises base plate 1, is characterized in that, base plate 1 is provided with drum support 11 and motor support 12, and motor support 12 is provided with motor 2, and one side of motor 2 is provided with first sprocket wheel 21; Rotary cylinder support 11 is provided with rotary cylinder 3, and the bottom of rotary cylinder 3 is provided with the second sprocket wheel 31 that cooperates with first sprocket wheel 21, and rotary cylinder 3 interior is provided with central shaft 32, and central shaft 32 and second sprocket wheel 31 Connect, the central axis 32 is provided with the helical bar 35 that rotates around the central axis 32, the top of the drum 3 is provided with the product output port 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com