Preparation method for solid powder dog-food flavoring agent

A technology of solid powder and flavoring agent, applied in the application, animal feed, animal feed and other directions, can solve the problems of affecting the selectivity and feed intake of dog food, rare solid products, poor product flavor, etc., to improve the utilization rate and Added value, good market prospects, and the effect of improving palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Grind the fat-free fresh chicken breast into minced meat;

[0028] (2) Add water to the minced meat obtained in step (1) at a weight ratio of 1:3, and stir thoroughly;

[0029] (3) Heat up the meat slurry obtained in step (2) to 45°C, adjust the pH to 6.0-7.0, and add 2% papain;

[0030] (4) Mechanically stir the meat slurry obtained in step (3) at 45°C for 6 hours, control the degree of hydrolysis to 28%-32%; then rapidly raise the temperature to 85°C-90°C, and continue stirring for 20 minutes;

[0031] (5) Add 1.0% chicken oil, 4.0% D-xylose, 1.0% L-cysteine hydrochloride, 0.5% vitamin B to the enzymatic hydrolysis product obtained in step (4) 1 , 1.0% food-grade phosphoric acid with a mass concentration of 85%, stir evenly;

[0032] (6) Continue heating the product obtained in step (5) at 115°C for 50 min;

[0033] (7) After adding 5% tara gum and 25% modified starch to the product obtained in step (6), stir evenly;

[0034] (8) Homogenize the product obtai...

Embodiment 2

[0036] (1) Grind the fat-free fresh chicken breast into minced meat;

[0037] (2) Add water to the minced meat obtained in step (1) at a weight ratio of 1:4, and stir thoroughly;

[0038] (3) Heat the meat slurry obtained in step (2) to 50°C, adjust the pH to 6.0-7.0, and add 1% flavor protease;

[0039] (4) Mechanically stir the meat slurry obtained in step (3) at 50°C for 4 hours, measure the degree of hydrolysis to 28%-32%; then rapidly raise the temperature to 85°C-90°C, and continue stirring for 20 minutes;

[0040] (5) Add 1.0% chicken oil, 4.0% D-xylose, 1.0% L-cysteine hydrochloride, 0.5% vitamin B to the enzymatic hydrolysis product obtained in step (4) 1 , 1.0% food-grade phosphoric acid with a mass concentration of 85% and then stir evenly;

[0041] (6) Continue heating the product obtained in step (5) at 115°C for 50 min;

[0042] (7) After adding 2% tara gum and 10% modified starch to the product obtained in step (6), stir evenly;

[0043] (8) Homogenize the...

Embodiment 3

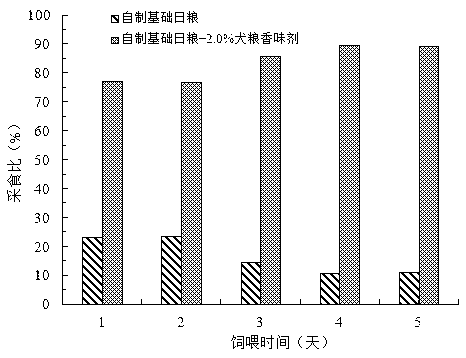

[0045] Five healthy adult Beagle dogs of similar size and weight that meet the requirements of animal experiment standards were used as experimental dogs; feeding place: standard kennel of Animal Experiment Center, School of Medicine, Nantong University; Humidity (55±5)%, light time: 7:00~19:00, one cage per cage. Carry out the palatability test of experimental dog food to determine the optimal addition amount and actual application effect of flavoring agent of the present invention.

[0046] 1. Experimental method

[0047] (1) Feed ratio test

[0048] Provide two food bowls for the experimental dogs at the same time period (9:00-15:00), put the same amount of but different dog food in each bowl, and record the food intake of the two kinds of dog food by the experimental dogs during this time period Ratio (the ratio of feed intake to the total amount of food, unit %), the dog food in the food bowl was reversed the next day, and the test was continued.

[0049] (2) First bit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com