End effector of clamp-shear integrated pick robot

A technology of picking robots and end effectors, which is applied in the field of agricultural robots, can solve problems such as fruit failure, failure to guarantee, and damage to fruits on the ground, and achieve the effects of simple and compact structure, reduced control difficulty, and enhanced practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

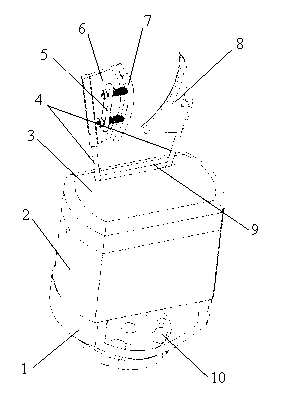

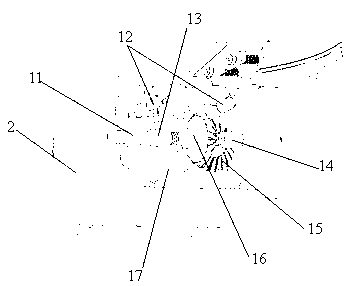

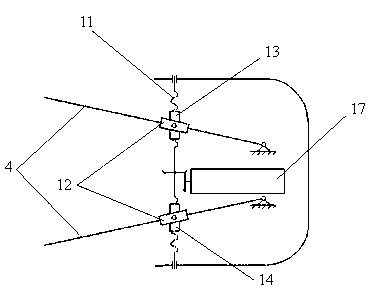

[0015] Such as Figure 1 ~ Figure 4 As shown, the greenhouse fruit and vegetable pick-up robot consists of a single-motor transmission system and an integrated finger-tip structure with clips and shears.

[0016] The single-motor transmission system includes a mounting seat 1, a housing 2, a front cover 3, a swing rod 4, a two-way screw 11, a sliding sleeve 12, a left-handed nut 13, a right-handed nut 14, a bevel gear at the motor shaft end 15, and a bevel between screw shafts. Gear 16 and motor 17; the motor 17 is fixed on the housing 2, the bevel gear 15 at the motor shaft end is fixed on the output shaft of the motor 17, the two-way screw rod 11 has two sections of symmetrical left-handed and right-handed threads, and the two ends of the two-way screw rod 11 Supported on the housing 2 by rolling bearings, the bevel gear 16 between the screw shafts is fixed between the left-handed thread and the right-handed screw thread of the two-way screw 11, one end of the two swing rods...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com