Anti-reflecting layer with progressive refractivity and manufacture method of anti-reflecting layer

An anti-reflection layer and refractive index technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of inability to achieve all-round, loss of anti-reflection function, and reduction of anti-reflection function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

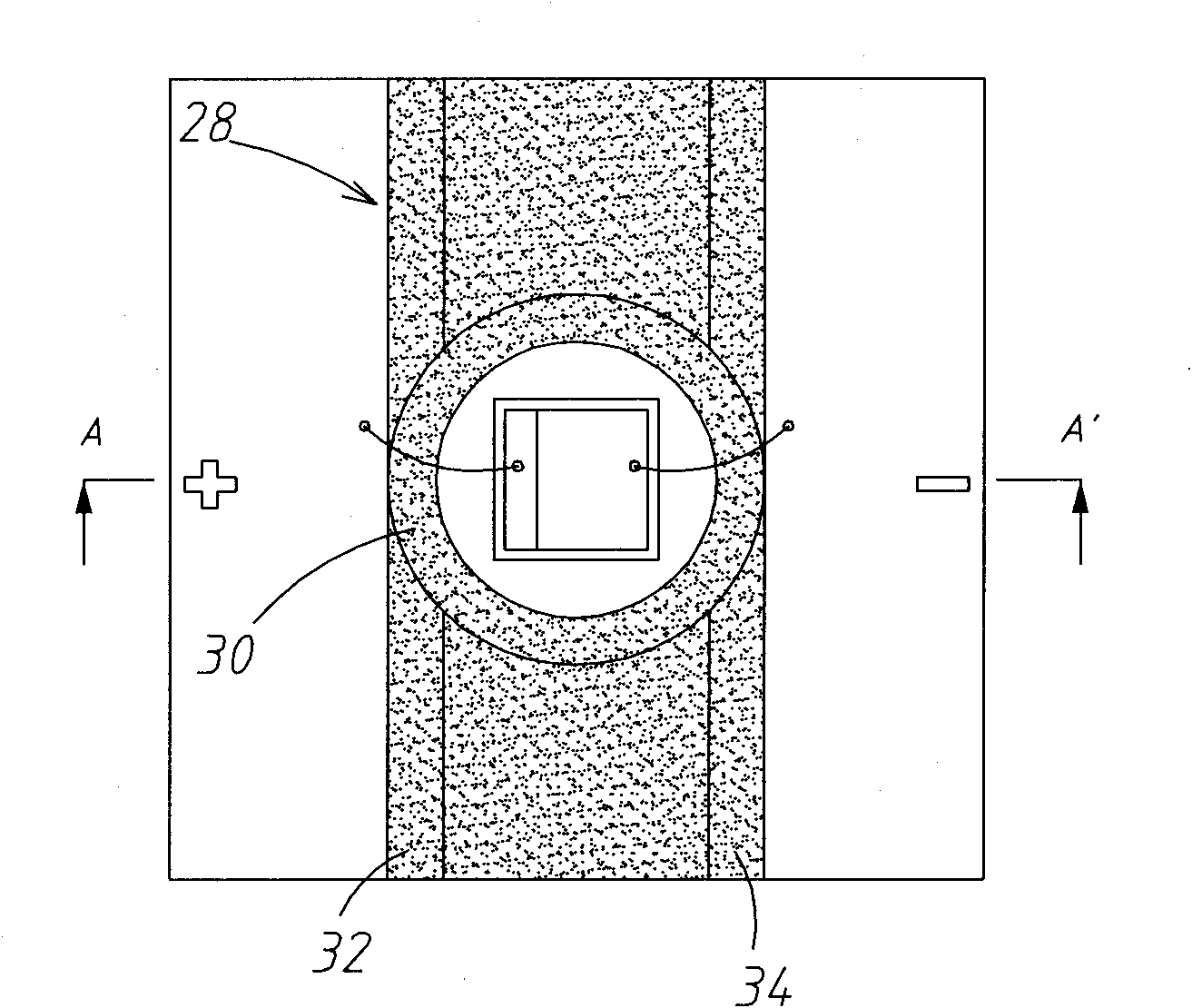

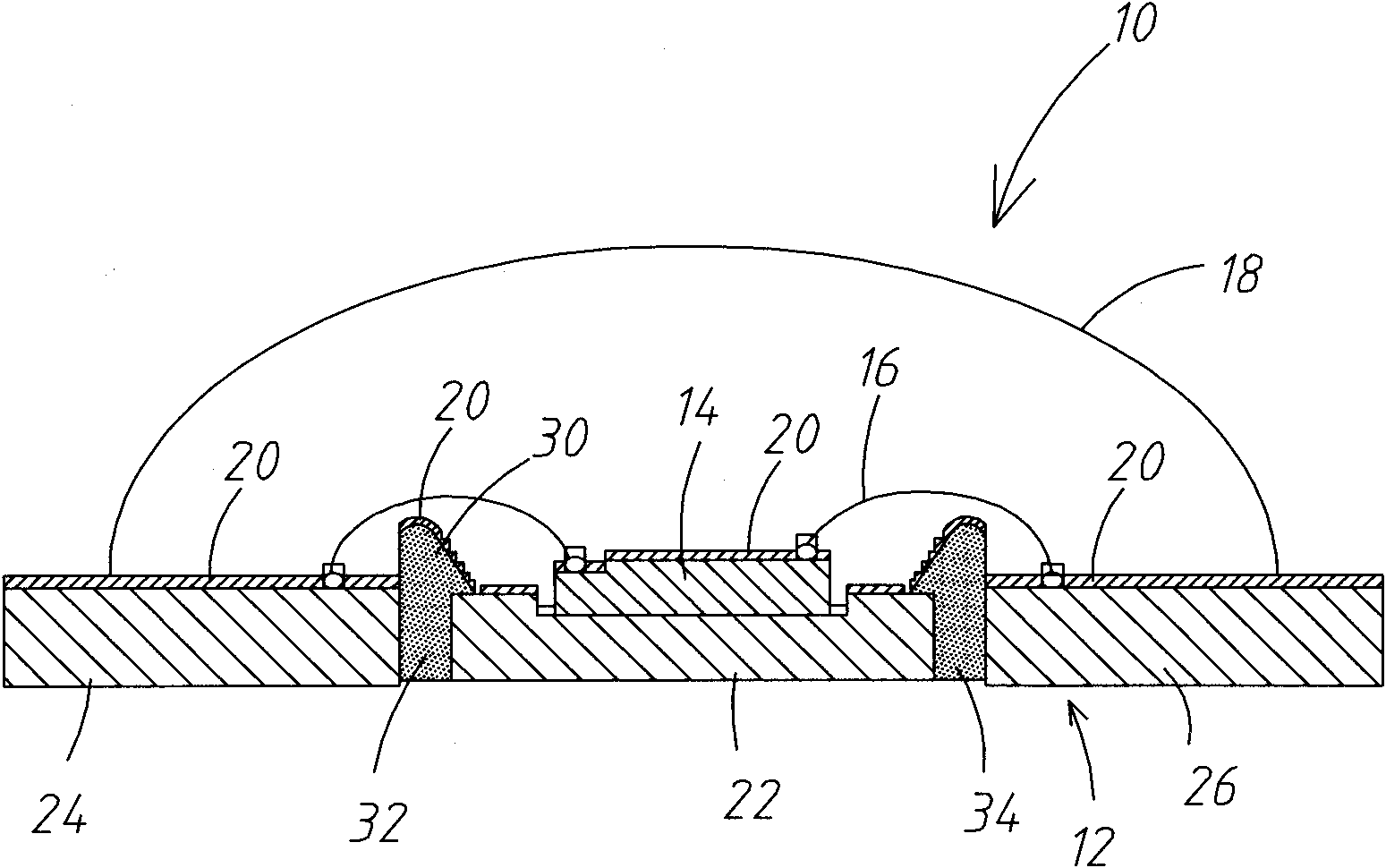

[0021] The present invention proposes an anti-reflection layer with progressive refractive index and its manufacturing method to eliminate the reflection of light at the interface. Furthermore, when applied to LEDs, the light extraction efficiency can be enhanced, and it can be applied to solar panels (Solar Cells) Surface, in order to reduce the ability to reflect sunlight, increase the incident rate of light and enhance the photoelectric effect.

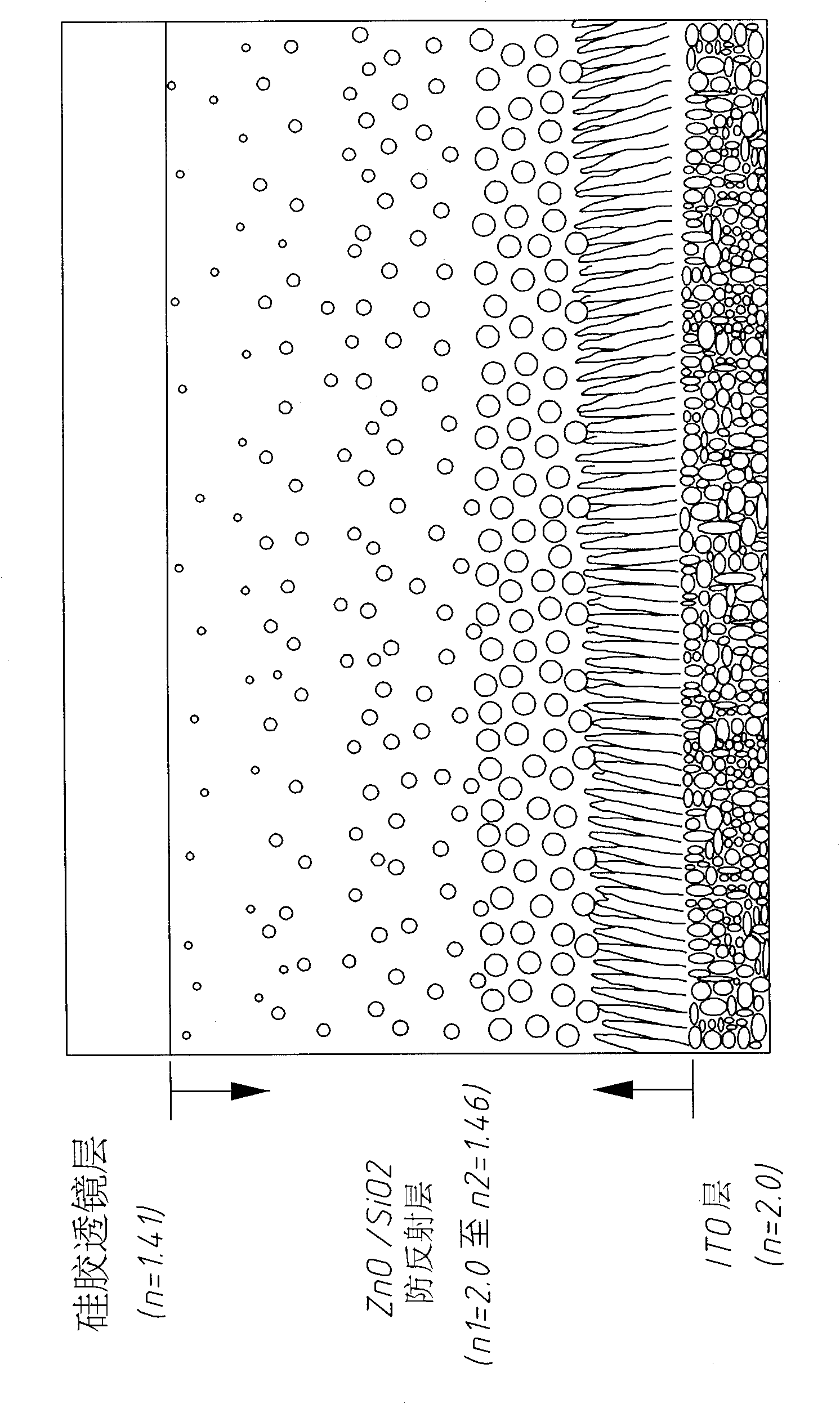

[0022] The present invention proposes an anti-reflection layer with progressive refractive index, which is characterized in that the anti-reflection layer is deposited from a first material and a second material, and the refractive index of the anti-reflection layer (n eff ) is the refractive index of the first material (n 1 ) and the refractive index of the second material (n 2 ) showed a gradual change. Wherein the refractive index of each thickness of the reflective layer conforms to an effective medium law (Effective Medium T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com