Inspection device of isolator

A technology of inspection devices and isolators, which is applied to measuring devices, instruments, and measuring electronics, can solve problems such as low efficiency, easy misoperation, troublesome wiring, etc., and achieve the effects of convenient use, improved safety, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

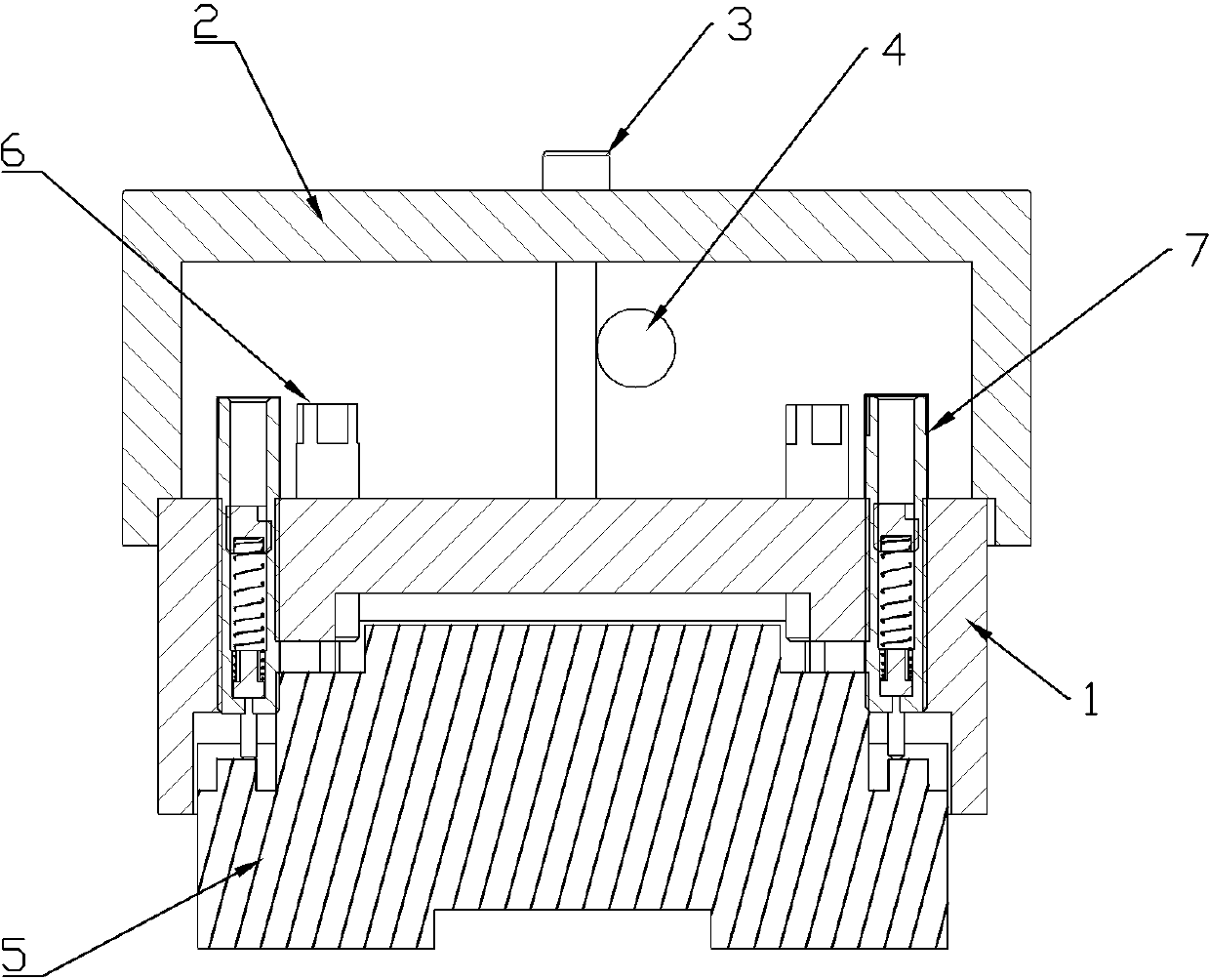

[0016] Embodiment one: see Figure 1 ~ Figure 3 , the isolator inspection device of the present invention includes an insulating seat 1 and an insulating cap 2, the lower end of the insulating seat 1 is matched with the insulating cap 2, and the upper end of the insulating seat 1 is designed as a stepped groove matching the end face of the isolator terminal block. The step groove on the seat 1 and the corresponding position of the terminal of the isolator 5 are provided with a corresponding number of positioning wire holes through the insulating seat 1, and a set of elastic probe systems are respectively installed in the positioning wire holes. The probe 10 of the elastic probe system protrudes from the stepped surface of the upper end of the insulating base 1, and connects with the conductor sleeve 7 to lead out the wires connected to the power supply and the inspection instrument respectively.

Embodiment 2

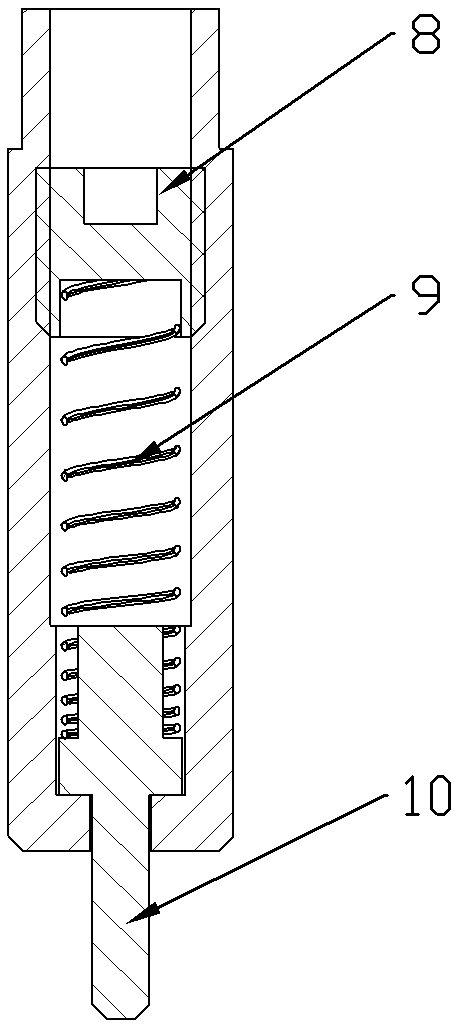

[0017] Embodiment two: see Figure 1 ~ Figure 3 The difference between the isolator testing device of this embodiment and the first embodiment is that a structure of the elastic probe system is further disclosed. The elastic probe system includes a conductor sleeve 7, a probe 10, a pressure cap 8 and a spring 9, the probe 10, spring 9 and pressure cap 8 are sequentially installed in the conductor sleeve, and the conductor sleeve 7 is matched and mounted on the insulating base 1 The elastic probe system is installed on the insulating base through the conductor sleeve in the positioning wire hole on the upper part.

Embodiment 3

[0018] Embodiment three: see Figure 1 ~ Figure 3 , the isolator inspection device of this embodiment, its structure is suitable for the inspection of isolators for eight terminal blocks. There are two steps and eight positioning wire holes on the insulating base 1. The two steps are opened inside the insulating base, which is symmetrical to the left and right. There are eight positioning screw holes and a fixed screw hole connected by bolt 3 on the upper end surface of the insulating base. The eight positioning wire holes have four at one end, symmetrical left and right, and eight copper sleeves are installed with threads in the wire holes, of which four long copper sleeves 7, four short pain sleeves 6, and four long copper sleeves 7 are symmetrically distributed on the outside. Four short copper sleeves 6 are symmetrically distributed on the inner side, and a set of elastic probe systems are installed in each of the copper sleeves. The probe system consists of probes 10, pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com