Water-electricity hybrid power cooling tower

A hybrid power and cooling tower technology, which is applied in the field of cooling towers, can solve the problems of rising cooling water temperature in cooling towers, insufficient power of water turbines, and inability to increase power of water turbines, etc., achieving obvious effects of ensuring safe production and energy-saving transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

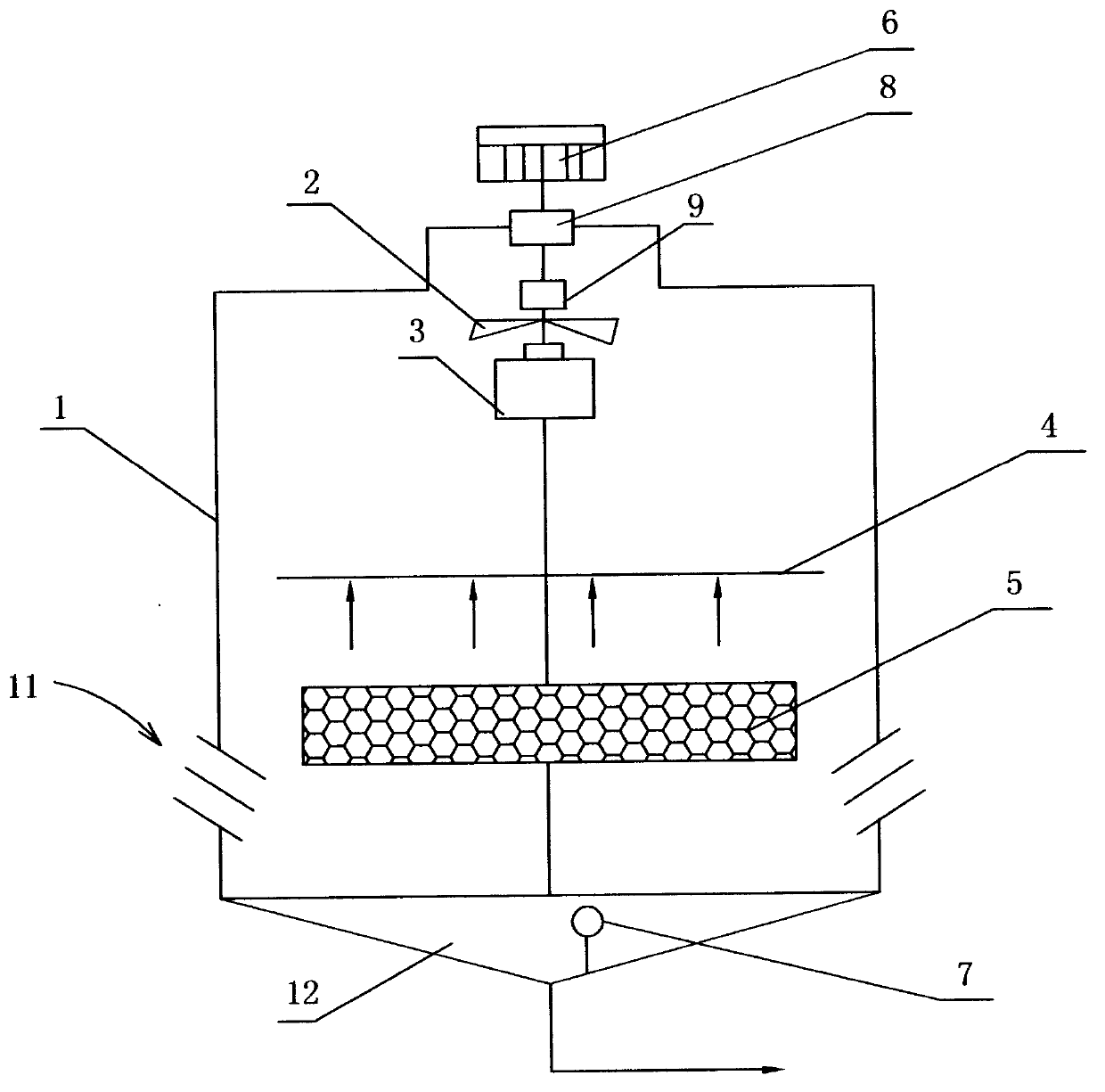

[0027] Example 1: see figure 1 , a hydroelectric hybrid cooling tower, which has: a tower body 1 surrounded by a shell, with a cold water outlet at the bottom; a fan installed on the top of the tower body and used to discharge hot and humid air inside the tower body 2. A water turbine 3 connected to the fan through the power output shaft, which is arranged on the upper part of the inner cavity of the tower body. The impeller in the water turbine is driven by the water flow of the water inlet pipe, and the impeller and the power output shaft of the water turbine are connected to each other in one body; a device The water distributor 4 in the inner cavity of the tower and the heat dissipation material 5 located under the water distributor and used for heat exchange between water and air. Common heat dissipation materials in this field are fillers, such as S-wave fillers, stepped trapezoidal ramp fillers, Point wave packing, two-way wave packing, oblique fold wave packing, obliqu...

Embodiment 2

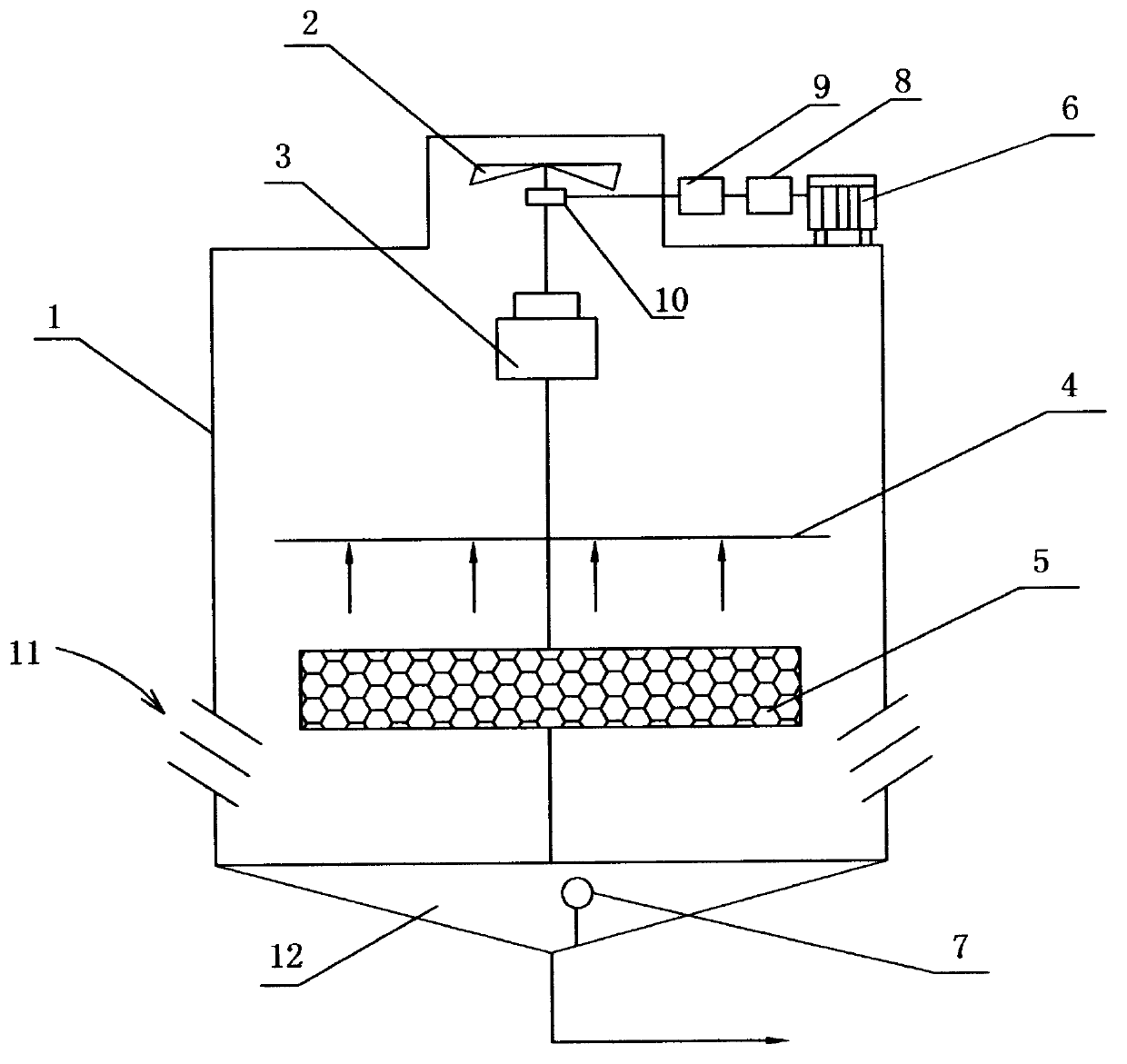

[0030] Example 2: see figure 2 , a transmission mechanism of a hydroelectric hybrid cooling tower includes: a transmission horizontally arranged, an automatic clutch, a hybrid power box, a transmission 8, which is connected between the motor and the automatic clutch; an automatic clutch 9, which is connected between the transmission and the power hybrid Between the boxes 10; a hybrid box 10, which is located between the automatic clutch, the output shaft of the water turbine and the power input shaft of the fan. Other structures of this case are the same as Embodiment 1, and are not described in detail here.

[0031] The hybrid power box rotates through the gears, so that the two powers of water energy and electric energy are superimposed, and the speed is increased to improve the cooling capacity of the cooling tower.

Embodiment 3

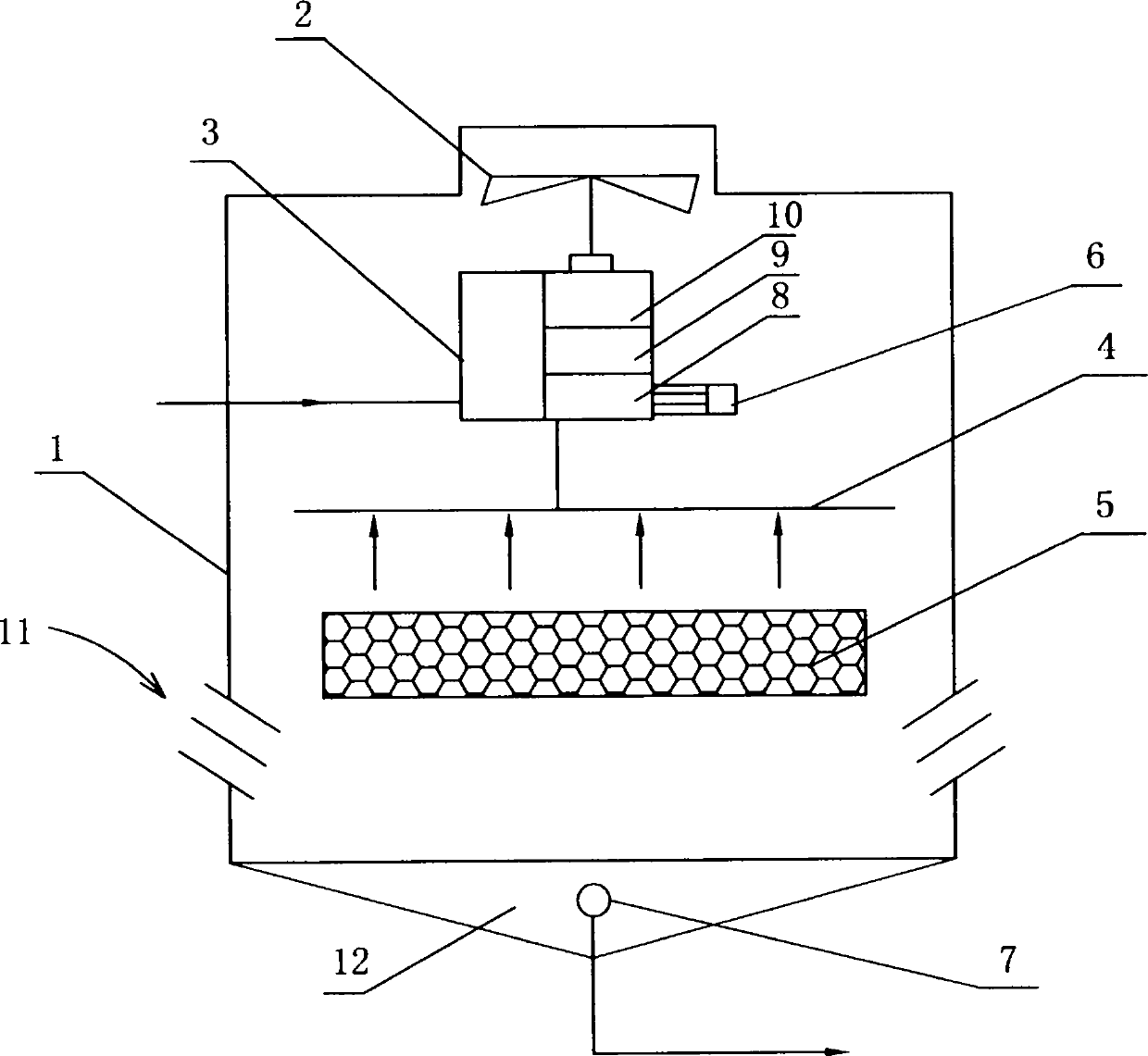

[0032] Example 3, see image 3 A transmission mechanism of a hydroelectric hybrid cooling tower includes: a transmission, an automatic clutch, a hybrid power box, a transmission 8, which is connected between the motor and the automatic clutch; an automatic clutch 9, which is connected between the transmission and the power mixing box 10 ; Hybrid box 10, which is located between the automatic clutch, the power output shaft of the water turbine and the power output shaft of the blower fan, the power unit and the transmission mechanism adopt an integrated structure in this case. The other structures of this case are the same as those in Embodiment 1, and will not be described in detail here.

[0033] The description of known technologies, such as transmission, automatic clutch, hybrid power box structure and its detailed assembly scheme, etc., is omitted herein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com