Housing structure of centrifugal compressor

A centrifugal compressor and shell structure technology, applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as increased maintenance costs, scrapped compressor shells, and surface damage, and facilitates processing and maintenance , the effect of reducing replacement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

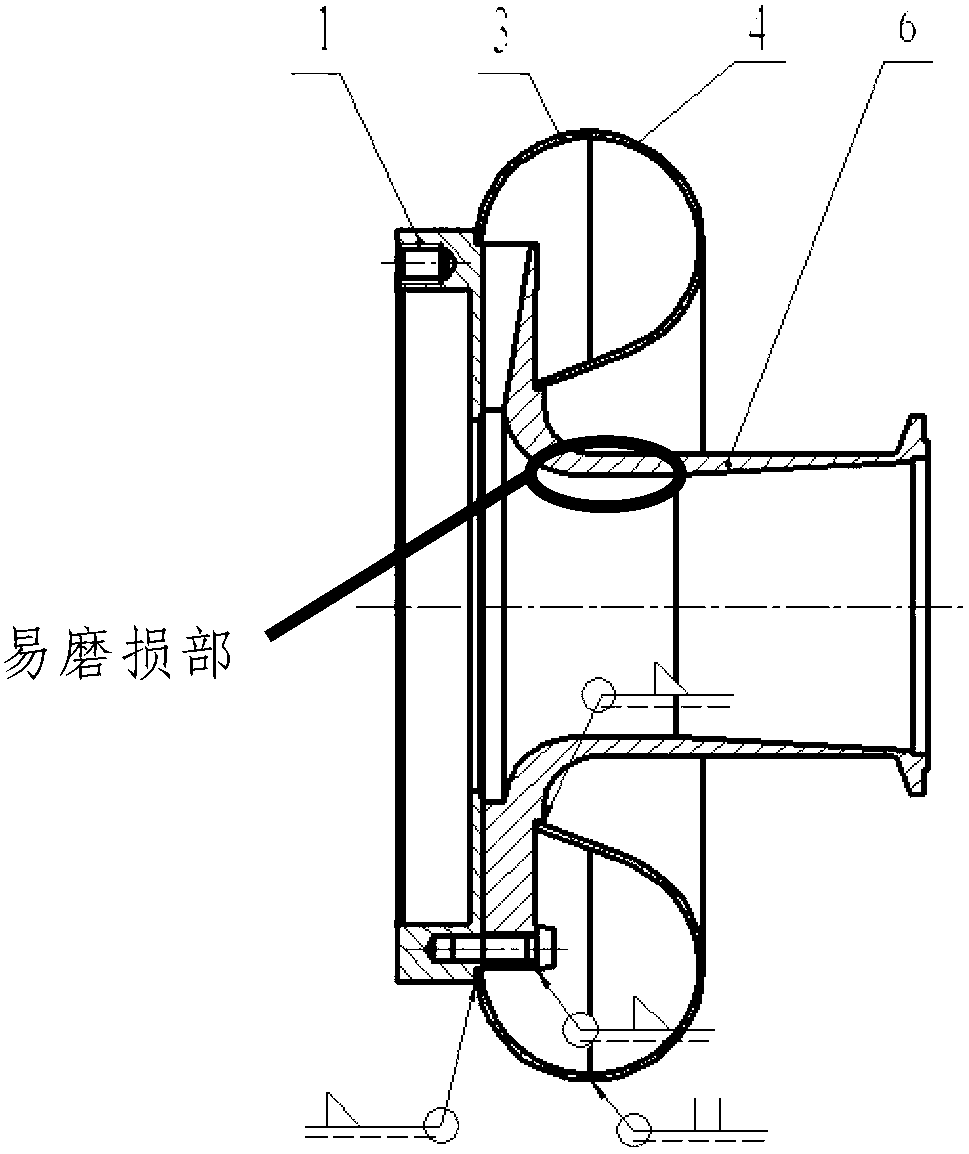

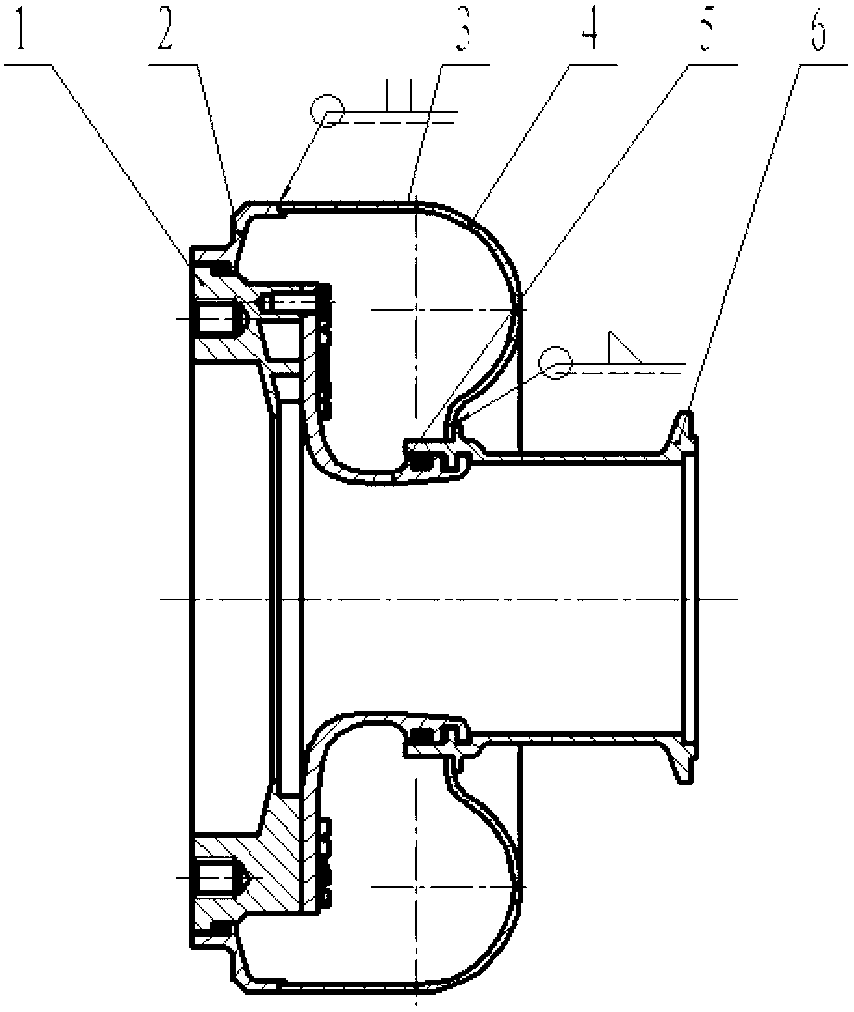

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings of the description, please refer to the attached description of the description figure 2 , 3 .

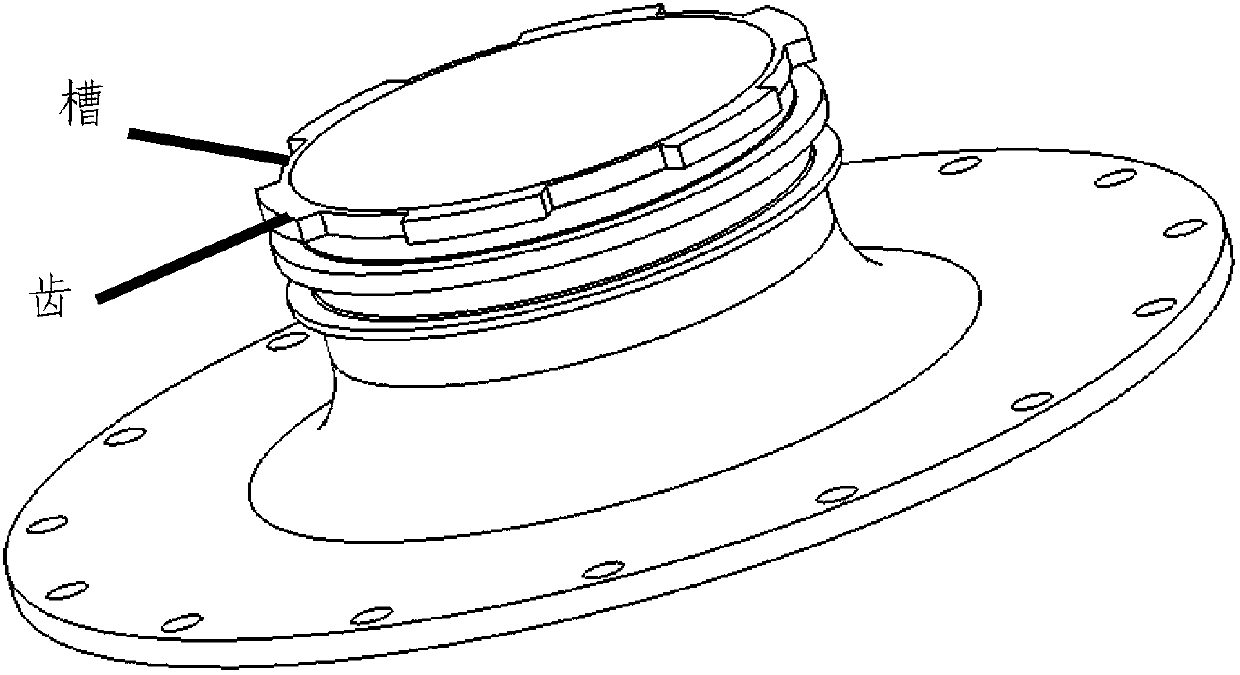

[0016] A casing structure of a centrifugal compressor, including a diffuser 1, a flange 2, a rear half volute 3, a front half volute 4, a cover plate 5 and an air intake nozzle 6. The flange 2, the rear half volute 3, the front half volute 4 and the air intake nozzle 6 are welded to form the compressor volute, and the cover plate 5 is arranged around the compressor impeller, and the front end of the cover plate 5 is clamped on the intake air through the tooth groove. A complete air duct is formed on the nozzle 6; the diffuser 1 is inserted into the flange 2, and screwed forward to the rear end surface of the cover plate 5.

[0017] Further, a positioning hole is provided on the rear end surface of the cover plate 5 , and a positioning pin is provided at a correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com