Fusion splicer for broken ends of hot melt wires

A fusion splicer and wire rod technology, applied in the field of additive manufacturing, can solve problems such as complex technology and equipment structure design, scrapped 3D printed parts, interruption of printing operations, etc., achieve broad market application prospects, good welding effect, and avoid waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

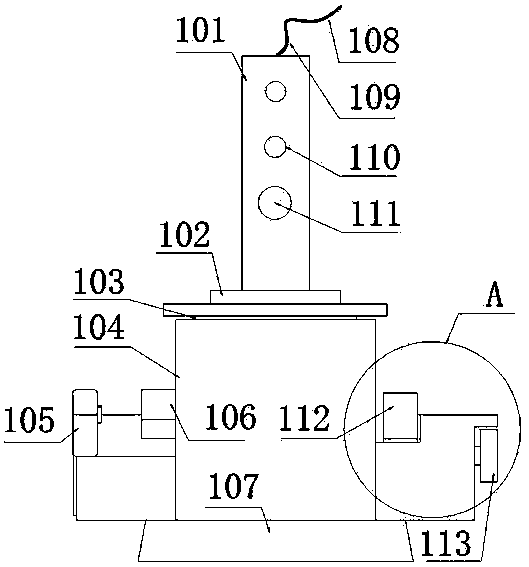

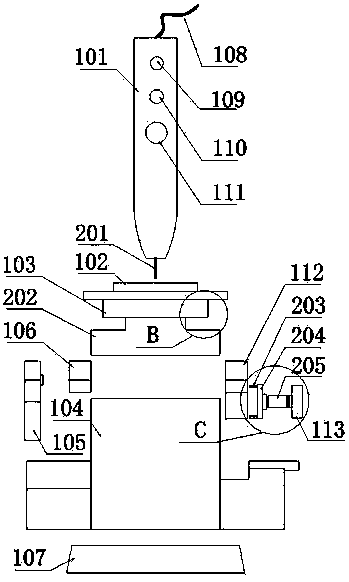

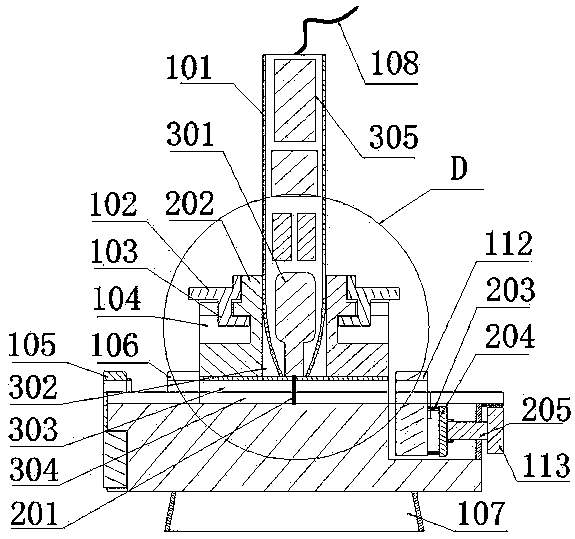

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 As shown, a fusion splicer for thermally fusible wires according to the present invention includes a slot base, an upper slot member, and a heating device. 106. Movable latch 112, push hand wheel 113; the lower latch 304 is set at the setting position of the base 104, and merges with the upper latch 303 provided by the upper latch member to form a tubular shape; the fixed latch 106 is fixed At the setting position of the base 104, the flip cover is opened and closed by the spring piece a401 and the movable hasp a403. The upper and lower grooves are arranged in the flip cover to form a tubular shape, and the diameter is equal to the diameter of the lumen formed by the upper slot 303 and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com