Support method for bolt-grouting composite crushing dynamic-pressure roadway soft rock roof by high-pre-stressed anchor cable

A high-prestressed, roof-supported technology, used in earth-moving drilling, bolt installation, mining equipment, etc., can solve problems such as high support strength, large section shrinkage, and inaccurate positioning of the crushed area, and achieve alleviation Stress problem, effect of reinforcement and stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

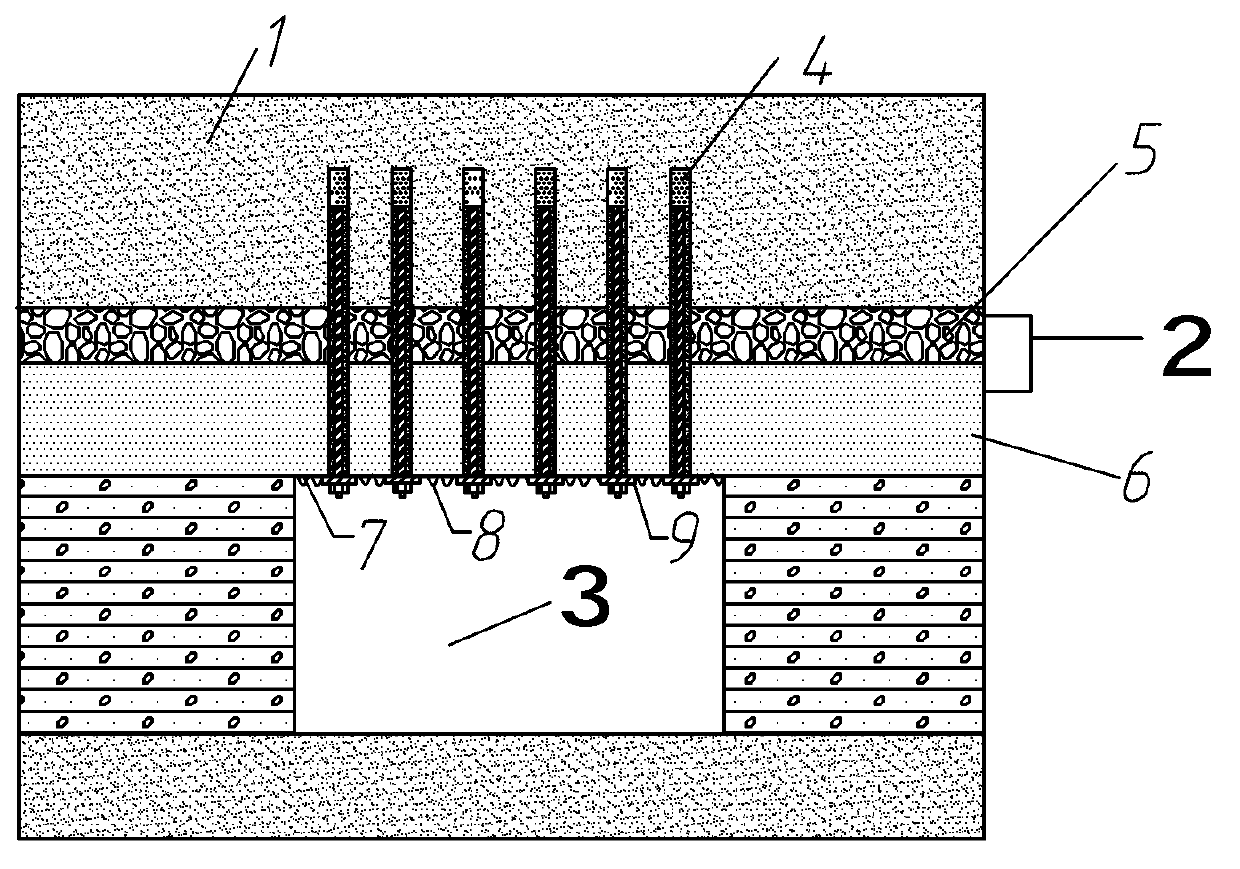

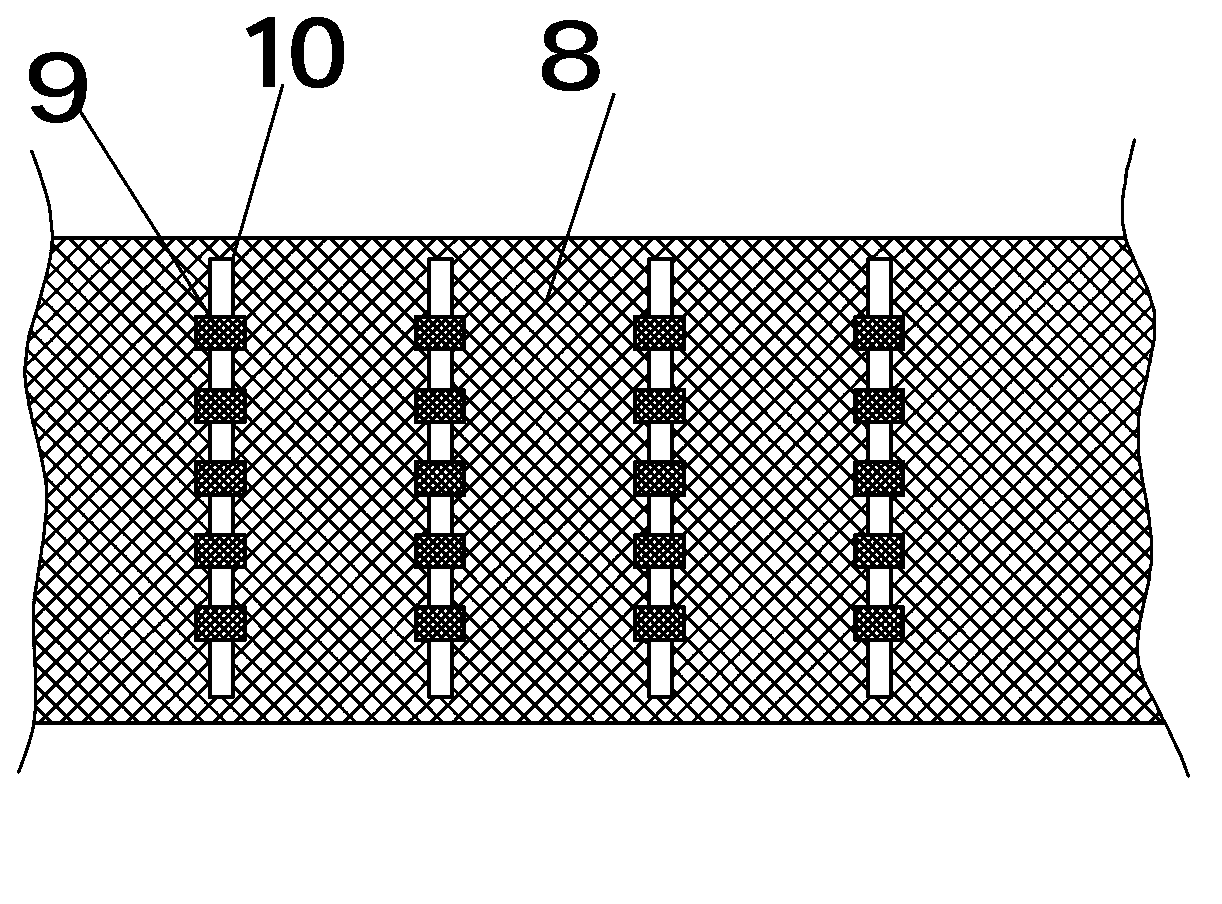

[0030] The present invention proposes a method for supporting the soft rock roof of a high-prestressed anchor cable, anchoring and grouting compound broken dynamic pressure roadway, which is based on the "key layer theory of rock formation control", the pressure support theory of "reserving a soft layer" and "The Theory of Coordinated Maintenance of Primary and Secondary Bearing Areas". According to a large number of on-site measured data and analysis in the past ten years, it is a common law that the distribution of tension and compression domains appears in the process of mechanical shape change of soft rock roadway surrounding rock, which is an important feature of deep surrounding rock deformation. First, use the deep hole camera detection instrument to collect data on the discontinuous surface of the surrounding rock of the deep roadway roof and the range and lithology of the broken area; Grouting holes are drilled on the surface of the rock. After installing the grouting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com