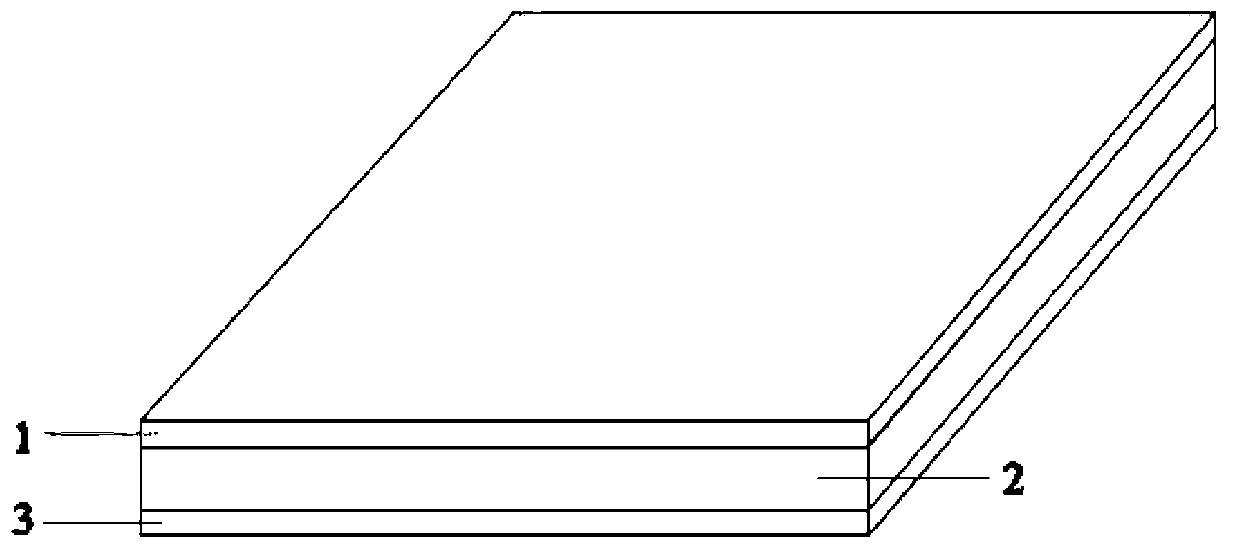

Composite expanded and vitrified microbead heat-insulation mortar slab with ceramsite-reinforced surfaces and production method thereof

A technology of expanded vitrified microbeads and thermal insulation mortar, applied in chemical instruments and methods, thermal insulation, building components, etc., can solve the problems of high surface strength, small overall bulk density, low thermal conductivity, etc. Contradictions with density, the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] Firstly prepare the dry mix according to the ratio of the upper and lower surface layers and the sandwich layer, wherein the composition and parts by weight of the upper and lower surface layers are: 100 parts of 42.5 grade cement, the particle size is 2-4mm, and the bulk density is less than 300Kg / m 3 100 parts of ultra-light ceramsite, with a bulk density of 100Kg / m 3 100 parts of expanded vitrified microbeads, 2 parts of redispersible latex powder (DN-4100), 0.3 parts of hydroxypropyl methylcellulose ether, 0.4 parts of polypropylene fiber, 0.9 part of wood fiber, Beijing Fortern Technology Co., Ltd. 0.01 parts of air-entraining agent for mortar produced by the company. The composition and parts by weight of the sandwich layer are: 100 parts of 42.5 grade cement, and the bulk density is 100Kg / m 3 100 parts of expanded vitrified microbeads, 2 parts of redispersible latex powder (DN-4100), 0.3 parts of hydroxypropyl methylcellulose ether, 0.4 parts of polypropylene fi...

example 2

[0021] Firstly prepare the dry mix according to the ratio of the upper and lower surface layers and the sandwich layer respectively, wherein the composition and parts by weight of the upper and lower surface layers are: 80 parts of 42.5 grade cement, the particle size is 2-4mm, and the bulk density is less than 300Kg / m 3 120 parts of ultra-light ceramsite, with a bulk density of 100Kg / m 3 80 parts of expanded vitrified beads, 1 part of redispersible latex powder (DN-4100), 0.4 part of hydroxypropyl methylcellulose ether, 0.2 part of polypropylene fiber, 0.8 part of wood fiber, and 0 part of air-entraining agent. The composition and parts by weight of the sandwich layer are: 80 parts of 42.5 grade cement, and the bulk density is 100Kg / m 3 80 parts of expanded vitrified microspheres, 1 part of redispersible latex powder (DN-4100), 0.4 parts of hydroxypropyl methylcellulose ether, 0.2 parts of polypropylene fiber, 0.8 part of wood fiber, and 0 parts of air-entraining agent . Po...

example 3

[0023] Firstly prepare the dry mixture according to the ratio of the upper and lower surface layers and the sandwich layer, in which the composition and weight parts of the upper and lower surface layers are: 120 parts of 42.5 grade cement, the particle size is 2-4mm, and the bulk density is less than 300Kg / m 3 80 parts of ultra-light ceramsite, with a bulk density of 100Kg / m 3 120 parts of expanded vitrified beads, 3 parts of redispersible latex powder (DN-4100), 0.2 part of hydroxypropyl methylcellulose ether, 0.6 part of polypropylene fiber, 1 part of wood fiber, and 0.02 part of air-entraining agent. The composition and parts by weight of the sandwich layer are: 120 parts of 42.5 grade cement, and the bulk density is 100Kg / m 3 120 parts of expanded vitrified microbeads, 3 parts of redispersible latex powder (DN-4100), 0.2 parts of hydroxypropyl methylcellulose ether, 0.6 parts of polypropylene fiber, 1 part of wood fiber, Beijing Fortern Technology Co., Ltd. 0.04 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Dry apparent density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com