RCS (reinforced concrete structure) combined node with continuous webs and partially-cut flanges

A technology of partial cutting and continuous web, applied in the direction of construction, building structure, etc., can solve the problems of difficult concrete pouring, affecting the construction progress, construction difficulties, etc., to save the formwork and its support, improve the construction efficiency, and reduce the self-weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

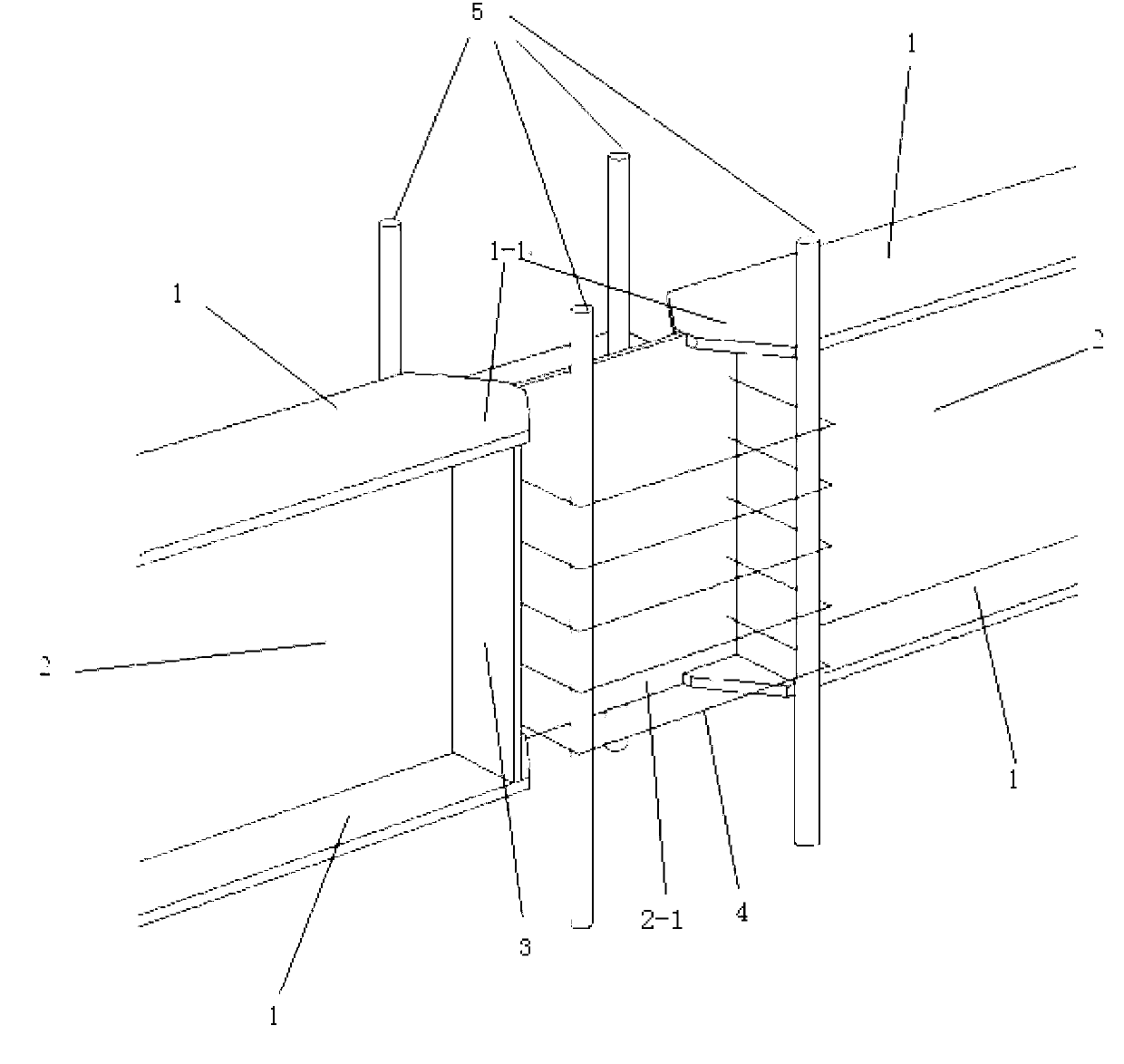

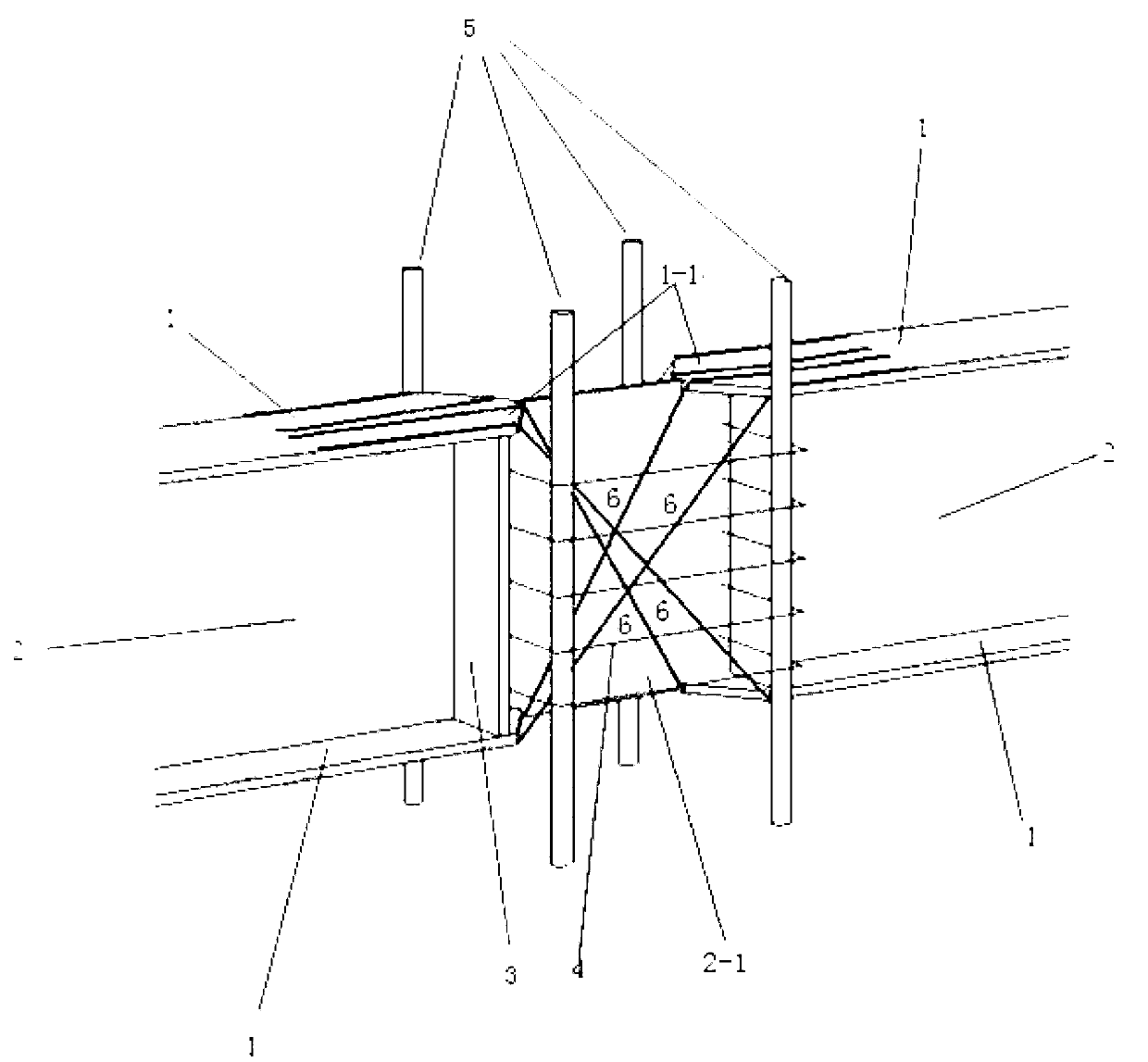

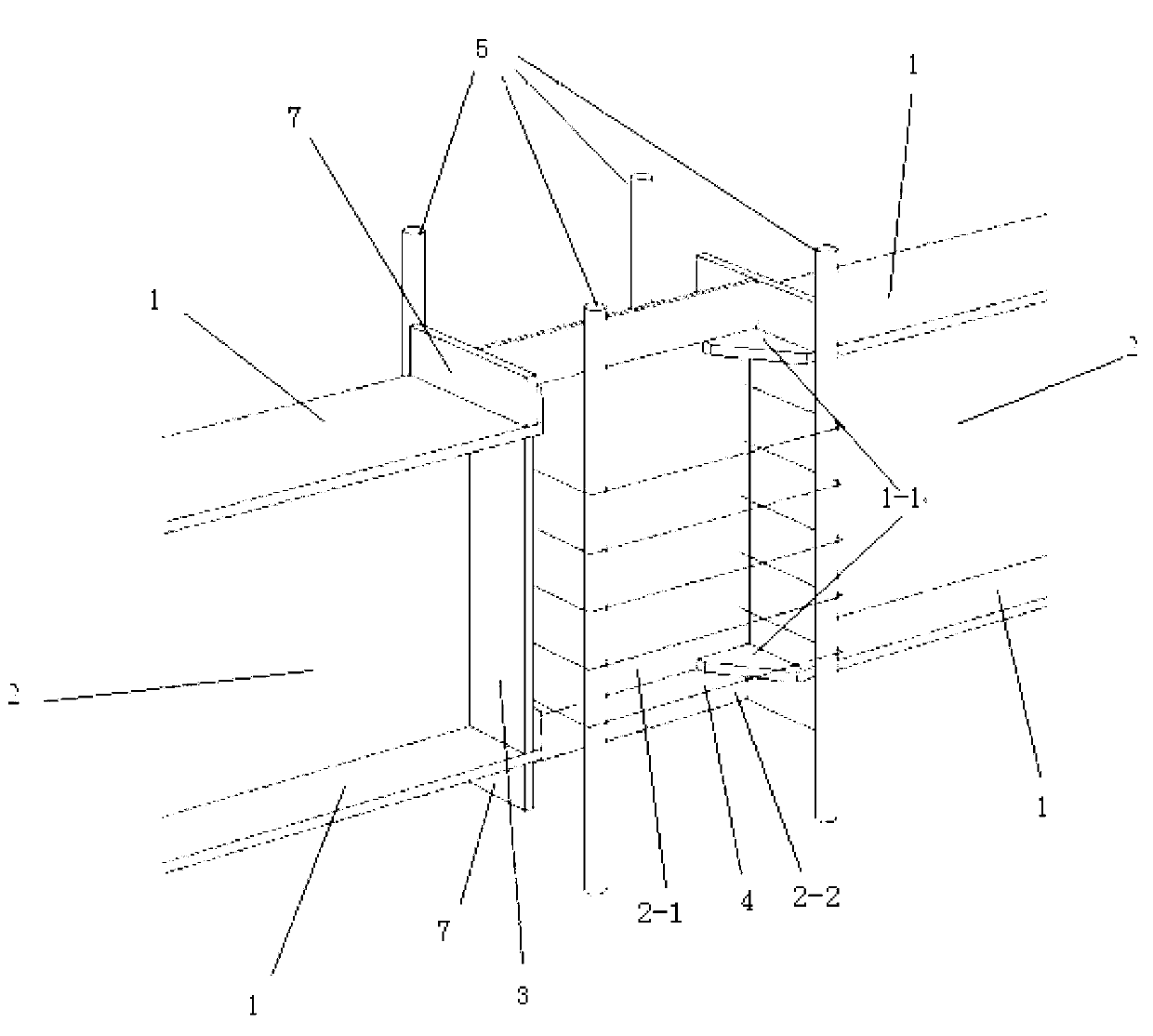

[0029] Such as figure 1 As shown, the RCS composite joint with continuous web and partially cut flange includes a reinforced concrete column and a steel beam vertically passing through the reinforced concrete column. or use section steel), the reinforced concrete column is composed of longitudinal steel bar 5, several layers of horizontally distributed stirrups 4 that are close to and around the longitudinal steel bar 5, and the steel beam flange that vertically passes through the reinforced concrete column is cut off, and the surrounding frame of the stirrup bar 4 passes through Through the joint web 2-1 connected with the steel beam web 2; the two ends of the joint web 2-1 are vertically distributed with surface bearing plates 3, and the surface bearing plates 3 are placed between the upper and lower flanges 1 of the steel beam; The core node is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com