Field simple assembly ultralong static load reference beam

An assembled and reference beam technology, which is applied in basic structure engineering, basic structure test, construction, etc., can solve the problems of leveling rod installation and observation difficulties, secondary observation data errors, uncertainty increase, etc., and achieve simple structure , Improve accuracy and reduce deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

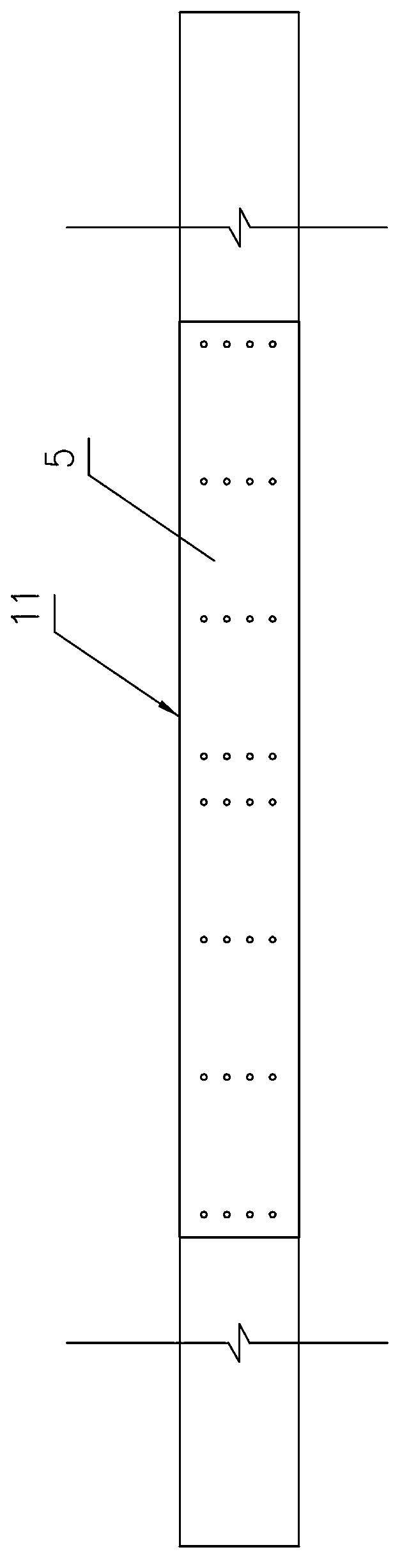

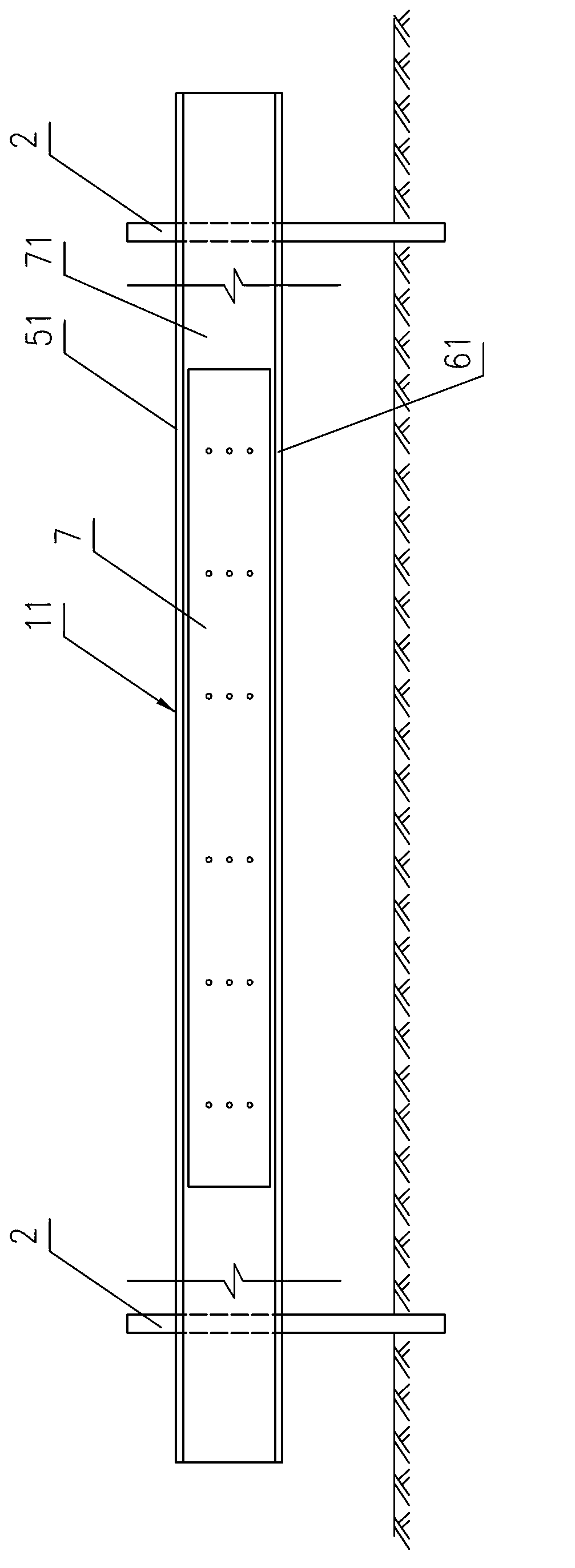

[0027] Such as Figure 1~4 Shown is a simple on-site assembly type super-long static load reference beam of the present invention, which includes two beam bodies 1 arranged side by side, see Figure 4 In this embodiment, the length of the beam body 1 is 24 meters, so that the setting position of the reference pile 2 of the load-bearing beam body 1 meets the design requirements; each beam body 1 is assembled by connecting several spliced beams. In the embodiment, the beam body 1 is assembled by butting two 12-meter-long splicing beams 11, that is, the splicing beams 11 are connected by a detachable connection structure. Avoid using secondary observations, keep the reference pile away from the buttress and keep a long enough distance from the inspected pile to ensure the accuracy of the pile foundation test data.

[0028] The splicing beam 11 is made of H-shaped steel. The upper flange 51, the lower flange 61 and the web 71 of the I-steel are respectively connected by a bolt conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com