Universal bridge cast-in-place support

A general-purpose, bridge technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of insufficient local stress distribution, damage to the integrity and integrity of materials, and inconvenient transportation of large components. , to achieve the effect of flexible assembly, convenient transportation and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

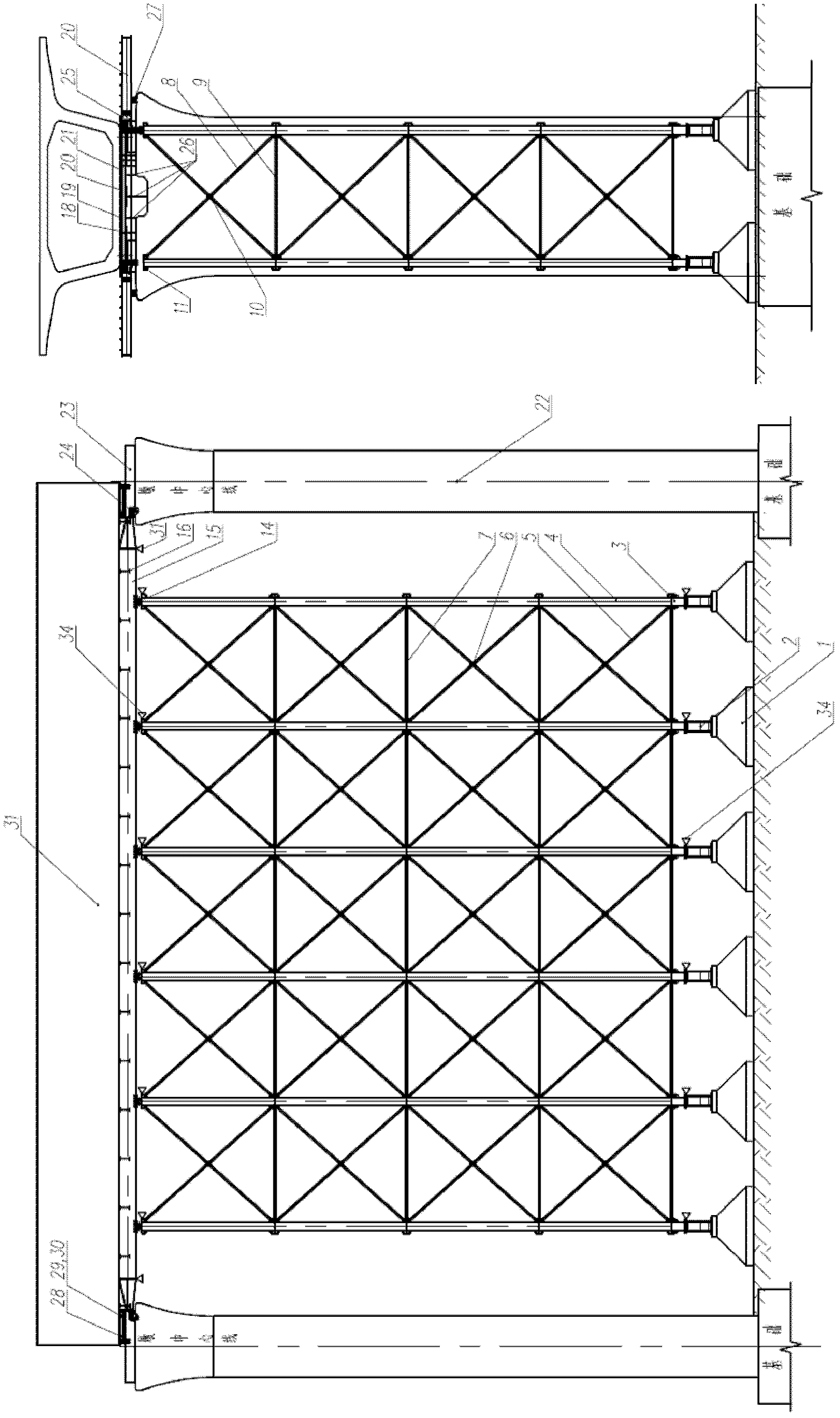

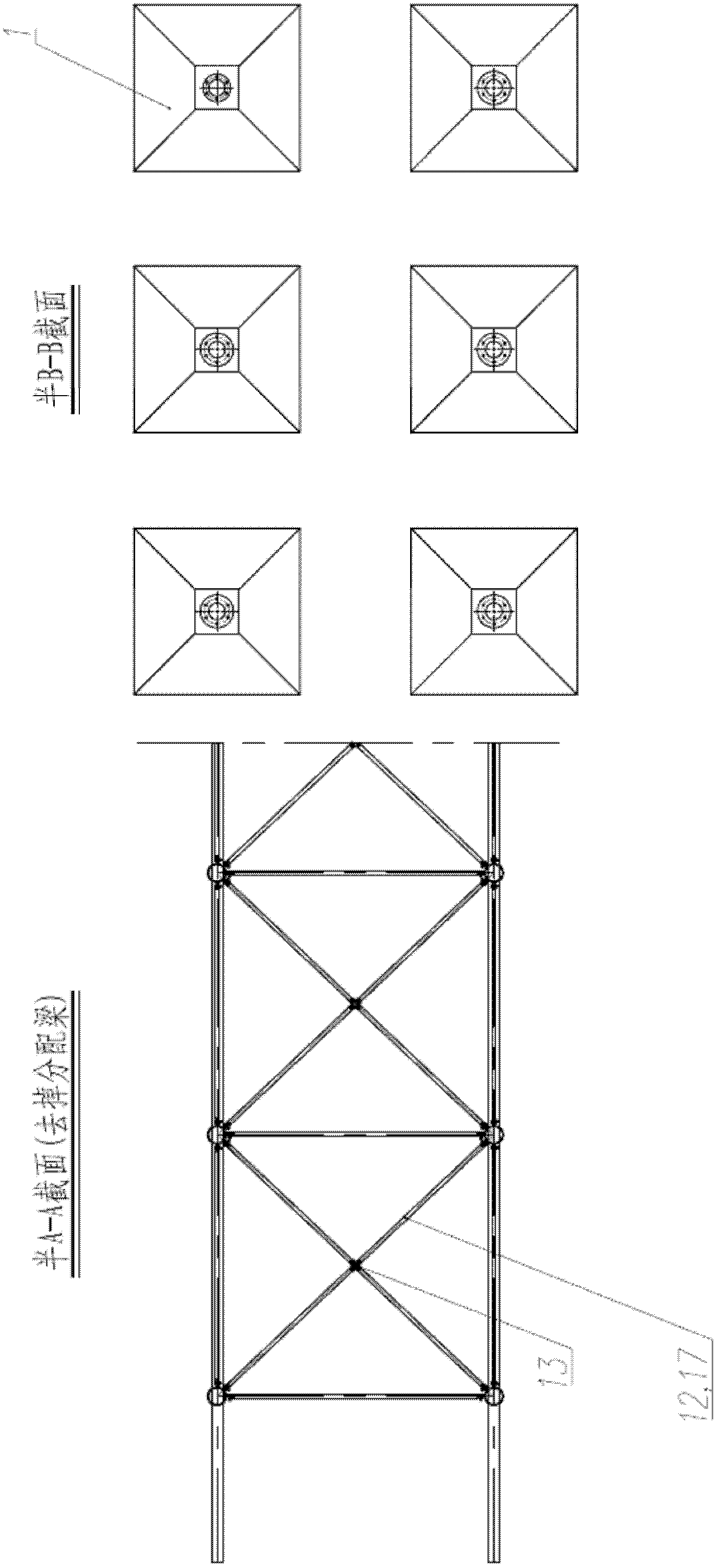

[0034] Implementation mode 1: The explanation is based on the cast-in-place construction of the 32.6m double-track simply supported box girder of the railway passenger dedicated line. Such as figure 1 Shown is a working state diagram of a universal cast-in-situ support for a bridge with a pier height of 20m or more. The specific assembly method is as follows:

[0035] 1. First select the required combination of concrete-filled steel tube column bottom section 3 and concrete-filled steel tube column 4 based on the height of the pier and the bottom curve of the beam;

[0036] 2. The foundation within a certain range at the bottom of the beam should be properly treated according to the specific situation. It is recommended that the foundation treatment plan is mainly digging down, and it is not recommended to fill or replace, because the support system has a good ability to adapt to the height difference of the foundation. Therefore, it is not necessary to require the foundation of th...

Embodiment approach 2

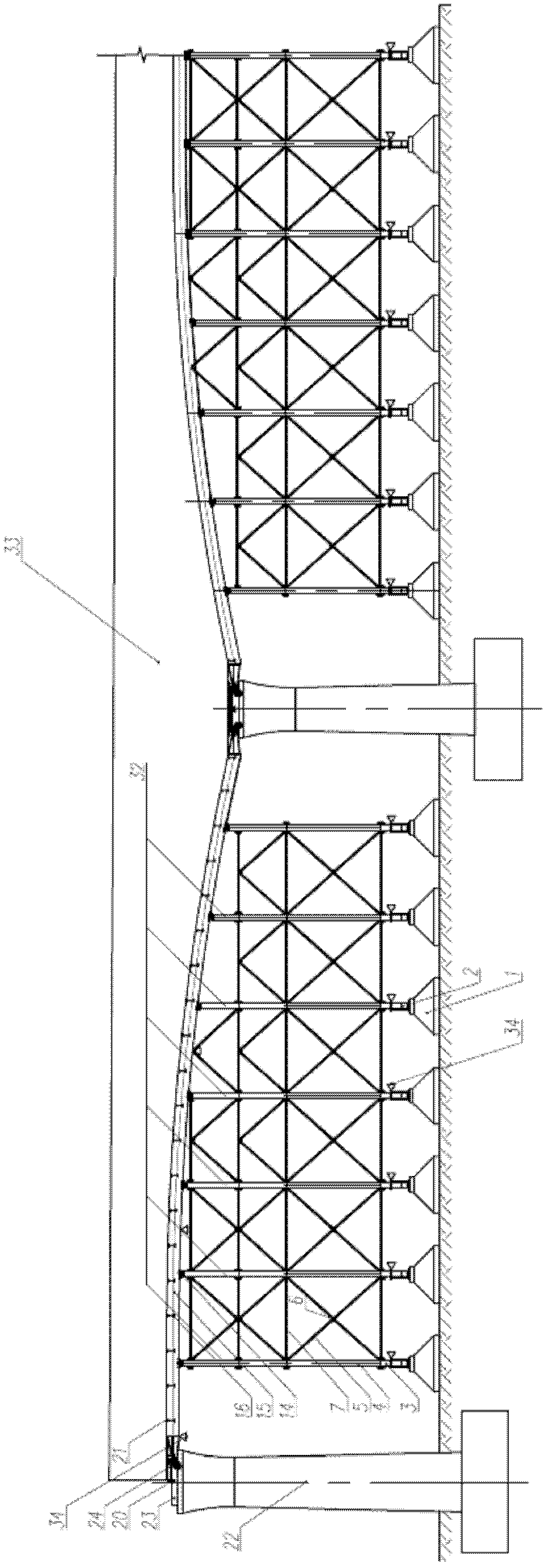

[0060] Embodiment 2: Here, the integral cast-in-place continuous beam with variable cross-section is taken as the object of description, and the specific application of the patent of the present invention is explained. Such as figure 2 The working state diagram of the universal bridge cast-in-place support of the present invention is shown for a continuous beam. The specific assembling method is the same as the method in the first embodiment. The characteristic is that the curve of the bottom of the beam changes so that the elevation of the bottom of the beam is not uniform, which requires more The adjustment section or a special column specially customized to adapt to the elevation of the bottom of the beam; and the dismantling method of the bracket is exactly the same as that described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com