Nano-grade high-precision-control hot filament chemical vapor deposition thin film material growth device

A vapor deposition, hot wire chemistry technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of slow growth at high temperature, large deposition area, hot wire aging, etc., to achieve easy integration, Good stability and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

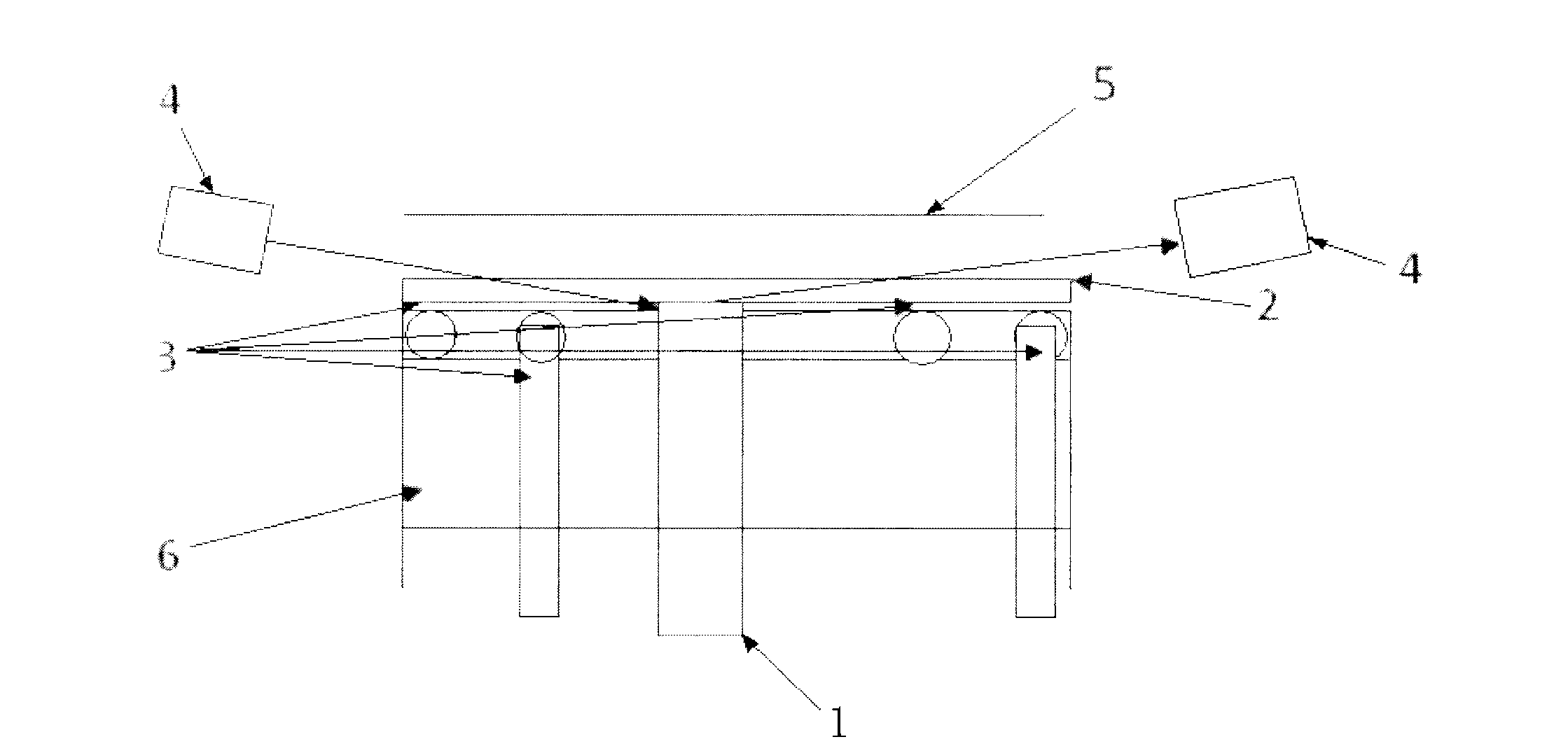

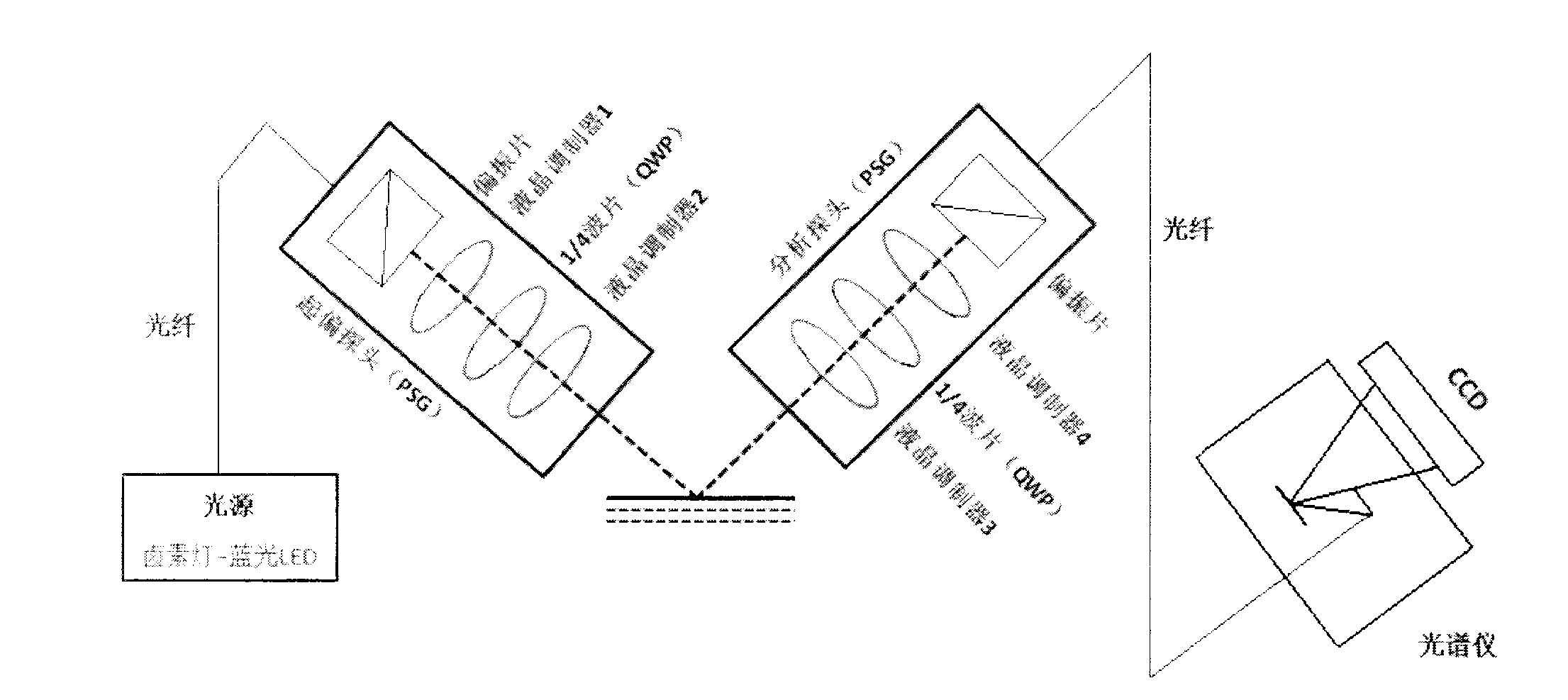

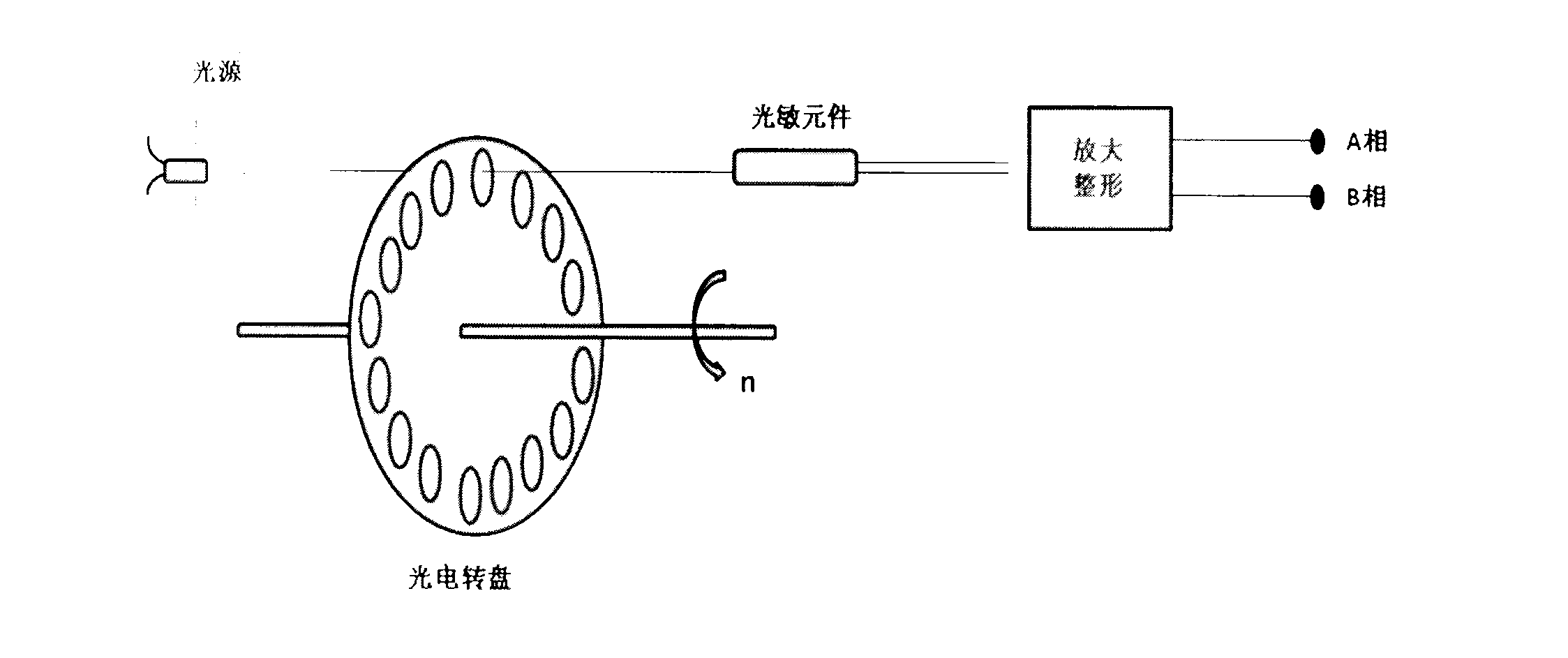

[0014] Such as figure 1 As shown, a nanoscale high-precision control hot wire chemical vapor deposition growth film material equipment mainly includes a vacuum system installed outside the deposition chamber, a gas system and a power control system, and also includes a built-in control device in the deposition chamber. The built-in control equipment includes a deposition table rotating rod 1, a deposition table system 2 installed above the deposition table rotating rod 1, a cooling system 3 installed on both sides of the deposition table rotating rod 1, and the deposition table rotating rod 1 is connected to the ellipse The polarizer 4 is connected, a hot wire plasma source system 5 is provided above the deposition platform system 2, and a servo motor position control system 6 is provided below the cooling system 3, and the servo motor position control system 6 includes a nanoscale high-precision Servo system precision controller, the deposition platform system 2 includes a na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com