Method for producing high-efficiency biological peptide through enzymolysis and microbe fermentation

A microbial fermentation and bio-peptide technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems that anti-nutritional factors cannot be completely removed, bitterness and odor cannot be completely controlled, and protein utilization is not high. , to achieve the effects of easy large-scale industrial production, low production cost and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

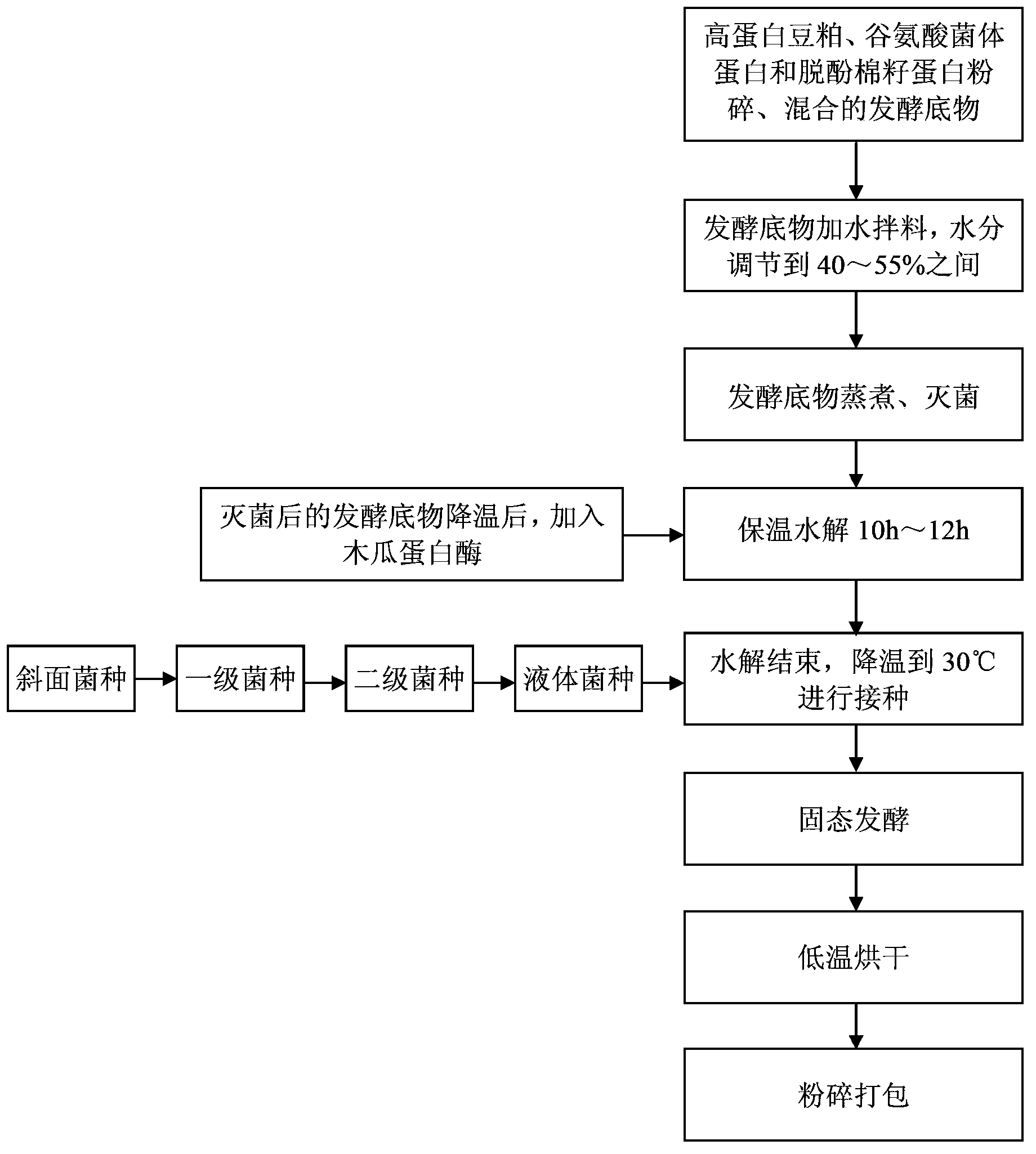

[0048] see figure 1 , prepare the biologically active peptide of this embodiment according to the following method:

[0049] 1. Mix 500kg of high-protein soybean meal, 200kg of glutamic acid bacterial protein, and 350kg of dephenolized cottonseed protein through a 40-mesh sieve to make a fermentation substrate.

[0050] 2. The fermentation substrate is mixed with water according to the material-water ratio of 1:1.2, and the moisture content of the material is adjusted to about 50%. , Cook and sterilize for 30 minutes under the condition of 0.11MPa.

[0051] 3. When the temperature of the sterilized fermentation substrate drops to 50°C, add 1 kg of papain (400,000 U / g) at a ratio of 1‰ of the weight of the fermentation substrate, and keep warm for 12 hours for hydrolysis.

[0052] 4. Aspergillus niger, Candida tropicalis, Aspergillus oryzae and Bacillus subtilis were subjected to enrichment culture and liquid fermentation according to the following methods:

[0053] (1) Aspe...

Embodiment 2

[0078] see figure 1 , prepare the biologically active peptide of this embodiment according to the following method:

[0079] 1. Mix 600kg of high-protein soybean meal, 100kg of glutamic acid bacterial protein, and 300kg of dephenolized cottonseed protein through a 40-mesh sieve to make a fermentation substrate.

[0080] 2. The fermentation substrate is mixed with water according to the material-water ratio of 1:1.2, and the moisture content of the material is adjusted to about 50%. , Cook and sterilize for 30 minutes under the condition of 0.11MPa.

[0081] 3. When the temperature of the sterilized fermentation substrate drops to 50°C, add 1 kg of papain (400,000 U / g) at a ratio of 1.5‰ of the weight of the fermentation substrate, and keep it warm for 12 hours for hydrolysis.

[0082]4. Aspergillus niger, Candida tropicalis, Aspergillus oryzae and Bacillus subtilis were subjected to enrichment culture and liquid fermentation according to the method described in Example 1, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com