Full-automatic packaging machine

A fully automatic packaging machine and packaging bag technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of inaccurate dosage, poor quality, large pollution, etc., and achieve accuracy, convenient operation, simple and ingenious Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

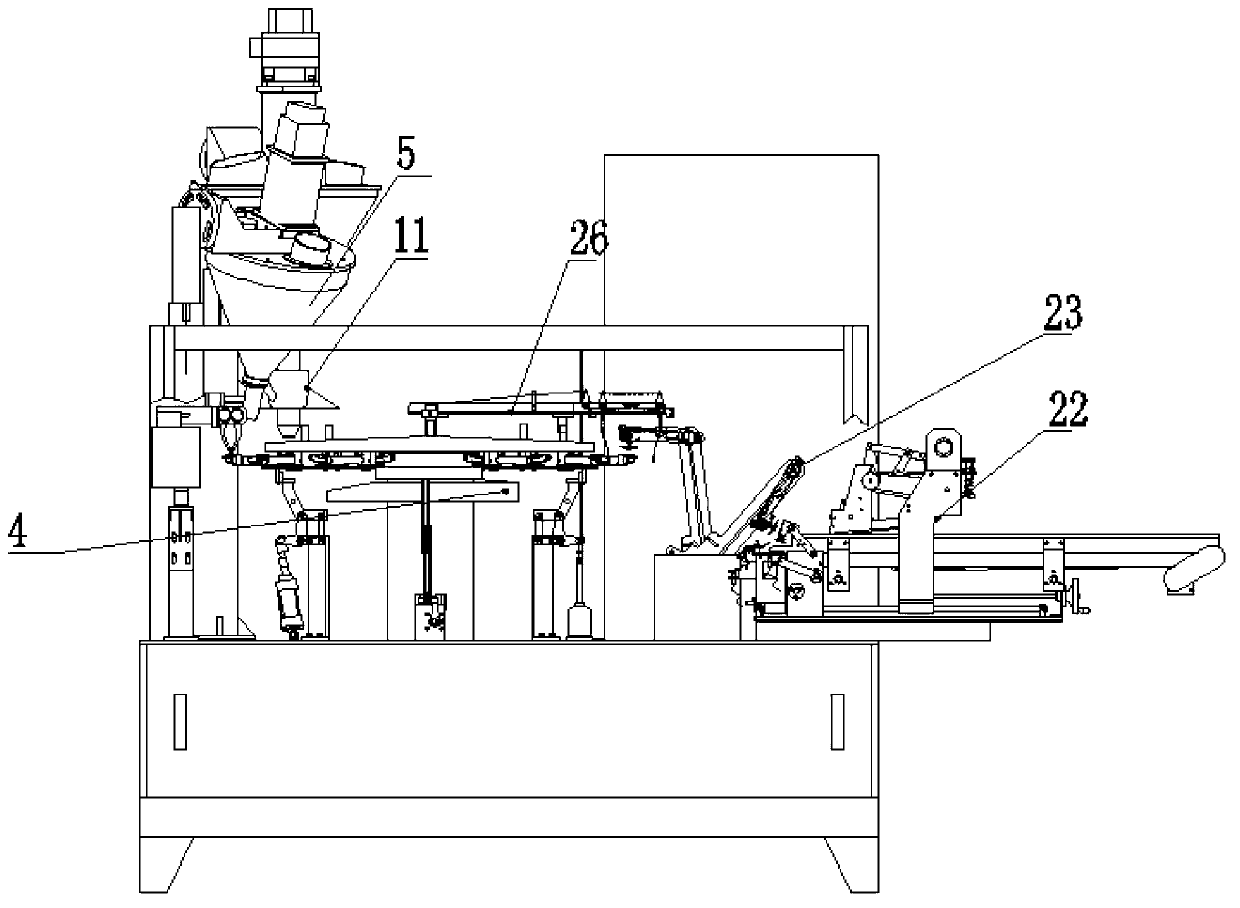

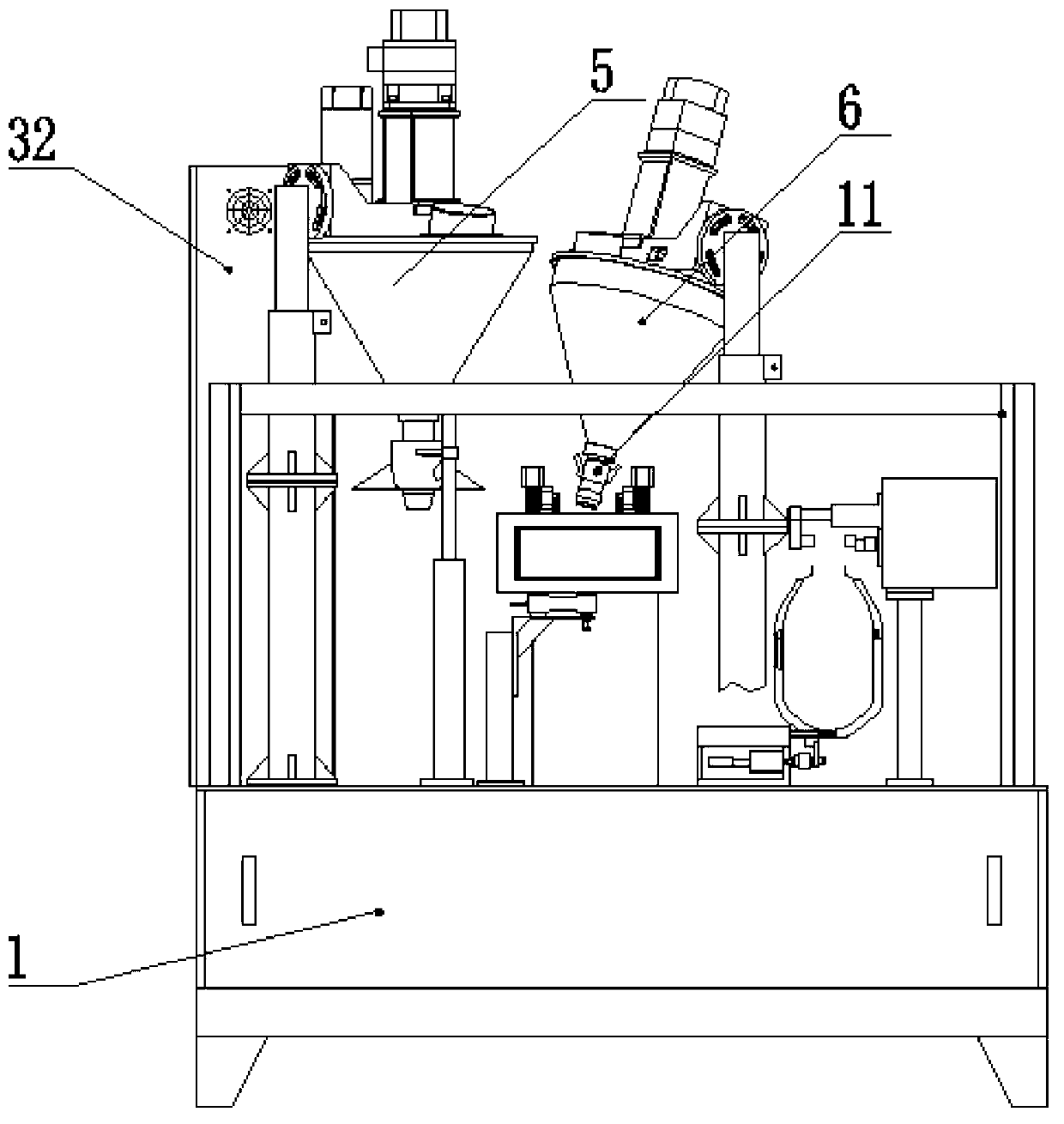

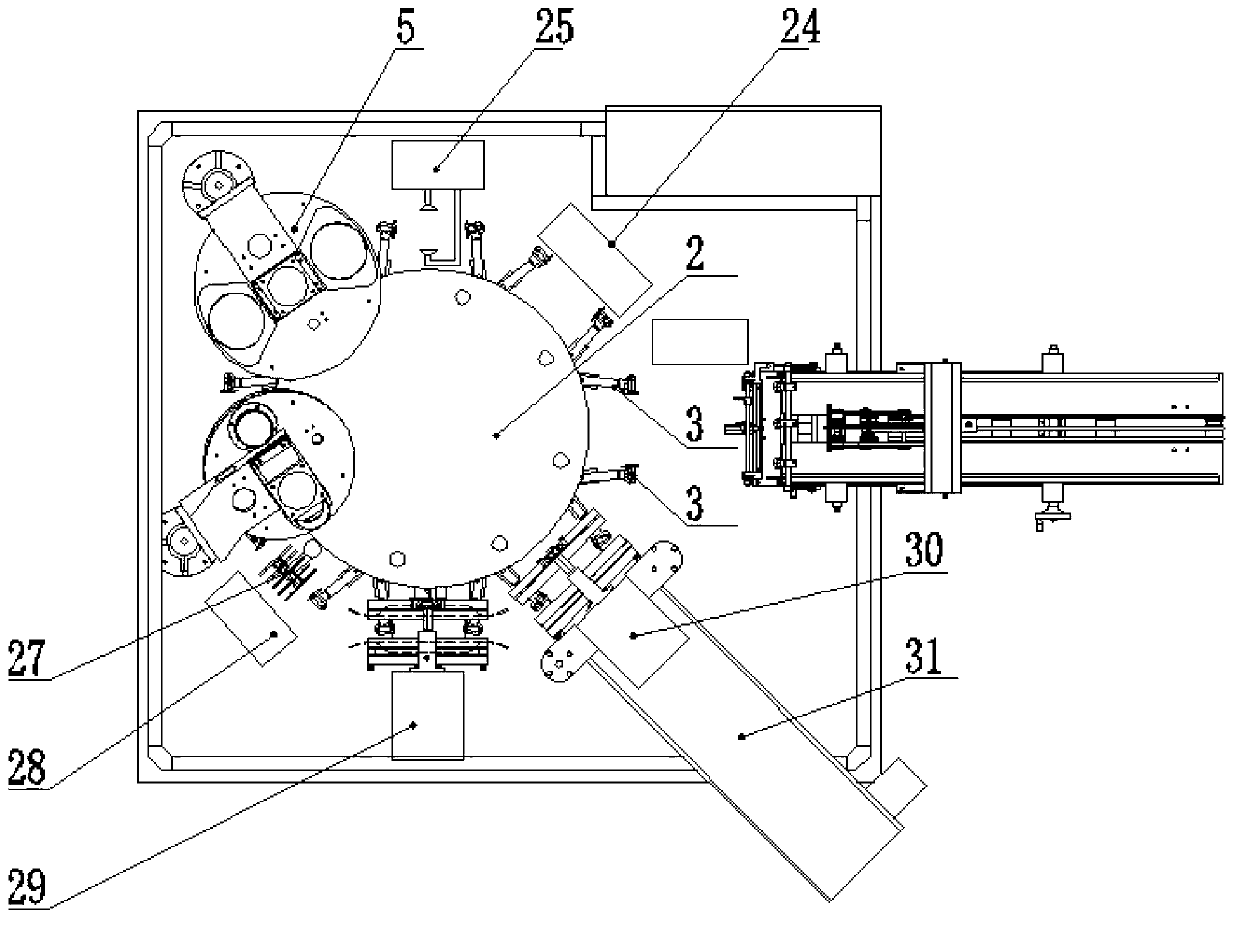

[0030] See Figure 1 to Figure 3, the fully automatic packaging machine of this embodiment includes a frame 1, a driving device arranged at the bottom of the frame 1, and a packaging execution device arranged at the top of the frame; the packaging execution device includes a driving disk 2, a claw arm 3, and a claw arm guide rail 4 , station and drive shaft; claw arm 3 comprises eight pairs, is arranged in pairs on the eighth equal position of driving disk; claw arm 3 and claw arm guide rail 4 are slidingly connected; driving device drives driving disk 2 to rotate through transmission shaft, Drive the claw arm 3 set on the drive plate 2 to slide on the claw arm guide rail 4; there are eight corresponding stations, each station corresponds to a pair of claw arms 3, and the counterclockwise order is: bag loading station , Coding station, bag opening station, rough filling station, fine feeding station, dust removal station, exhaust heat sealing station and cold pressing shaping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com