Oil-pressing and flour-milling machine

A pulverizing machine and pulverizing technology, applied in the direction of presses, manufacturing tools, etc., can solve problems such as single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

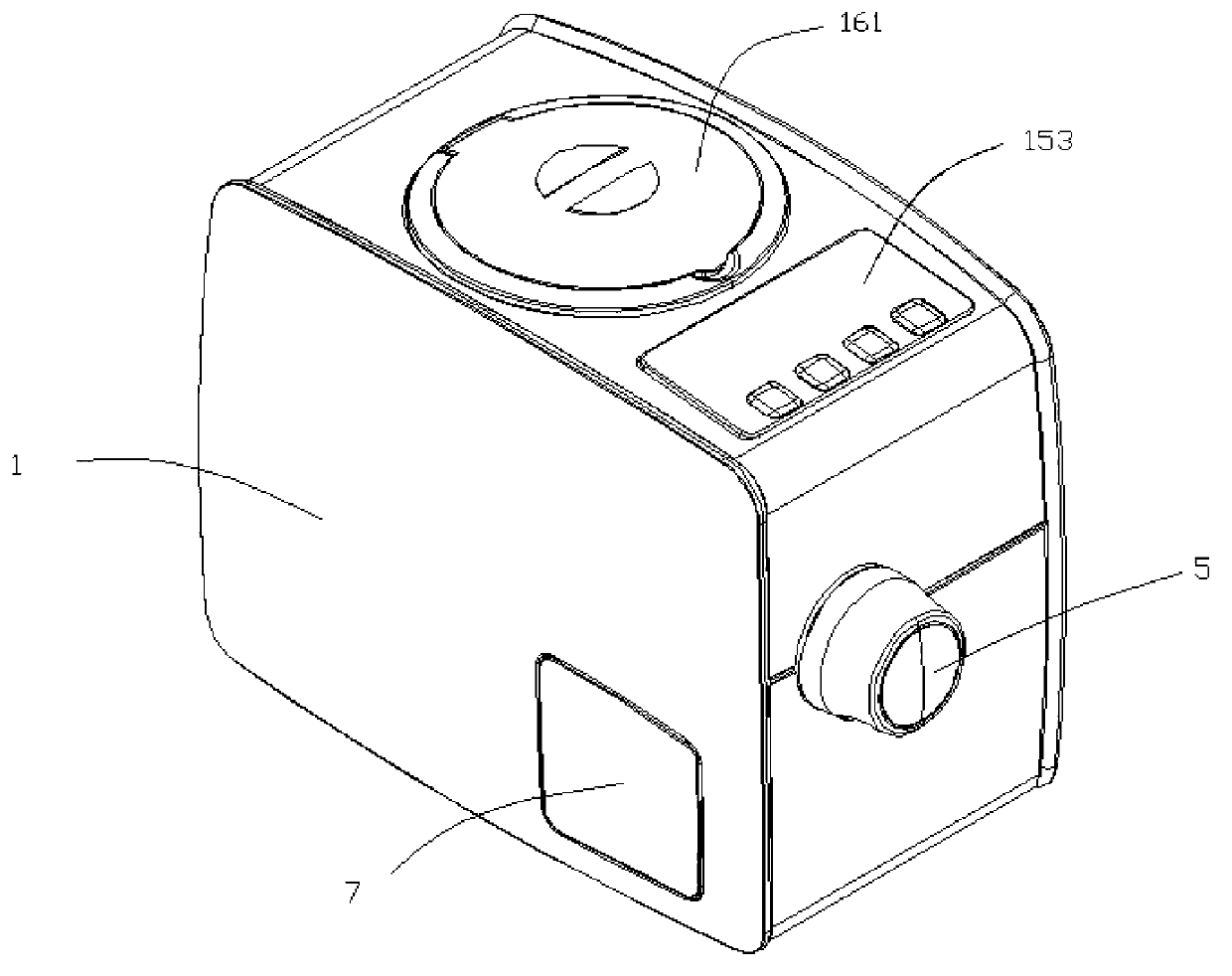

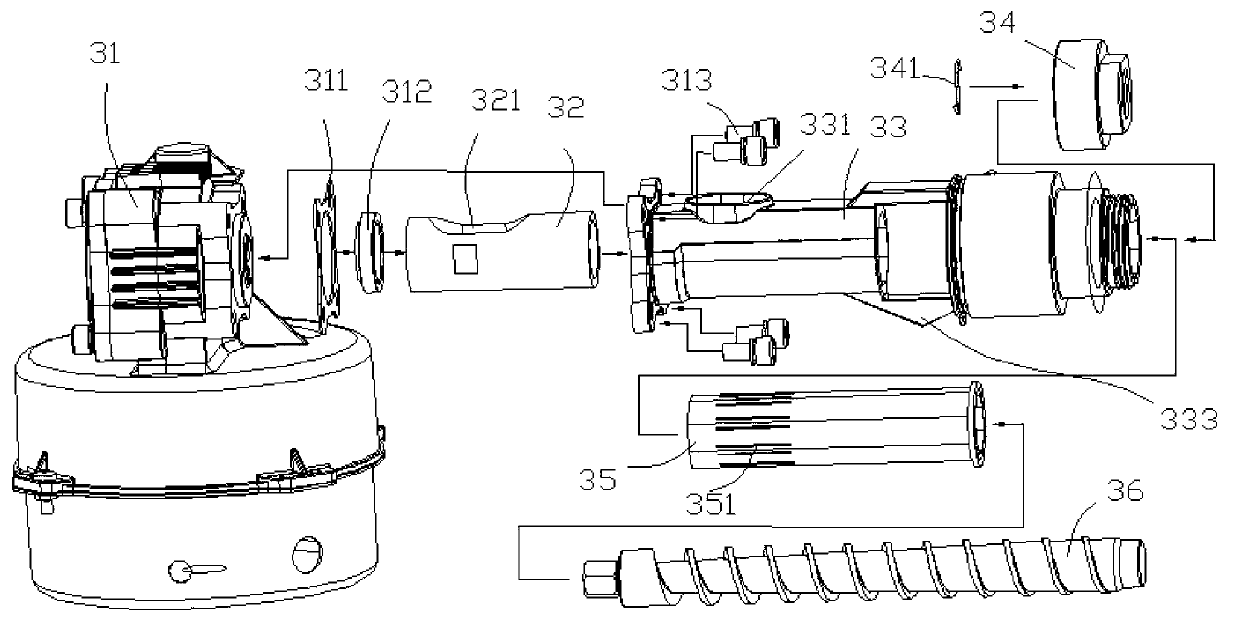

[0026] The oil press mill includes a shell 1, an inner frame 2 arranged inside the shell, an oil press body 3 provided in the accommodation space of the inner frame, and a program control board 4 inside the shell. The front cover 11 , the rear cover 12 , the left side cover 13 , the right side cover 14 and the upper cover 15 constitute the shell 1 , and the shell 1 and the inner frame 2 protect and support the oil press body 3 .

[0027] The loam cake 15 of shell 1 is provided with hopper 16, and hopper 16 top is provided with hopper cover 161, and loam cake 15 below is provided with protection switch 151 near hopper cover 161, and protection switch 151 is connected with program control panel 4. The hopper cover 161 can be closed on the top of the hopper 16, and the cover of the hopper cover 161 touches the protection switch 151, and the protection switch 151...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com