Small multifunction belt sander

A multi-functional, abrasive belt machine technology, applied in the direction of abrasive belt grinders, grinding machines, metal processing equipment, etc., can solve the problems of low processing precision, inconvenient operation, low work efficiency, etc., and achieve high work efficiency and convenient tension adjustment Accurate, easy-to-operate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0040] The principle of abrasive belt forming grinding is a forming grinding process that grinds and polishes the surface of the workpiece with the corresponding contact mode, appropriate grinding parameters and high-speed moving forming rollers and abrasive belts according to the shape of the workpiece.

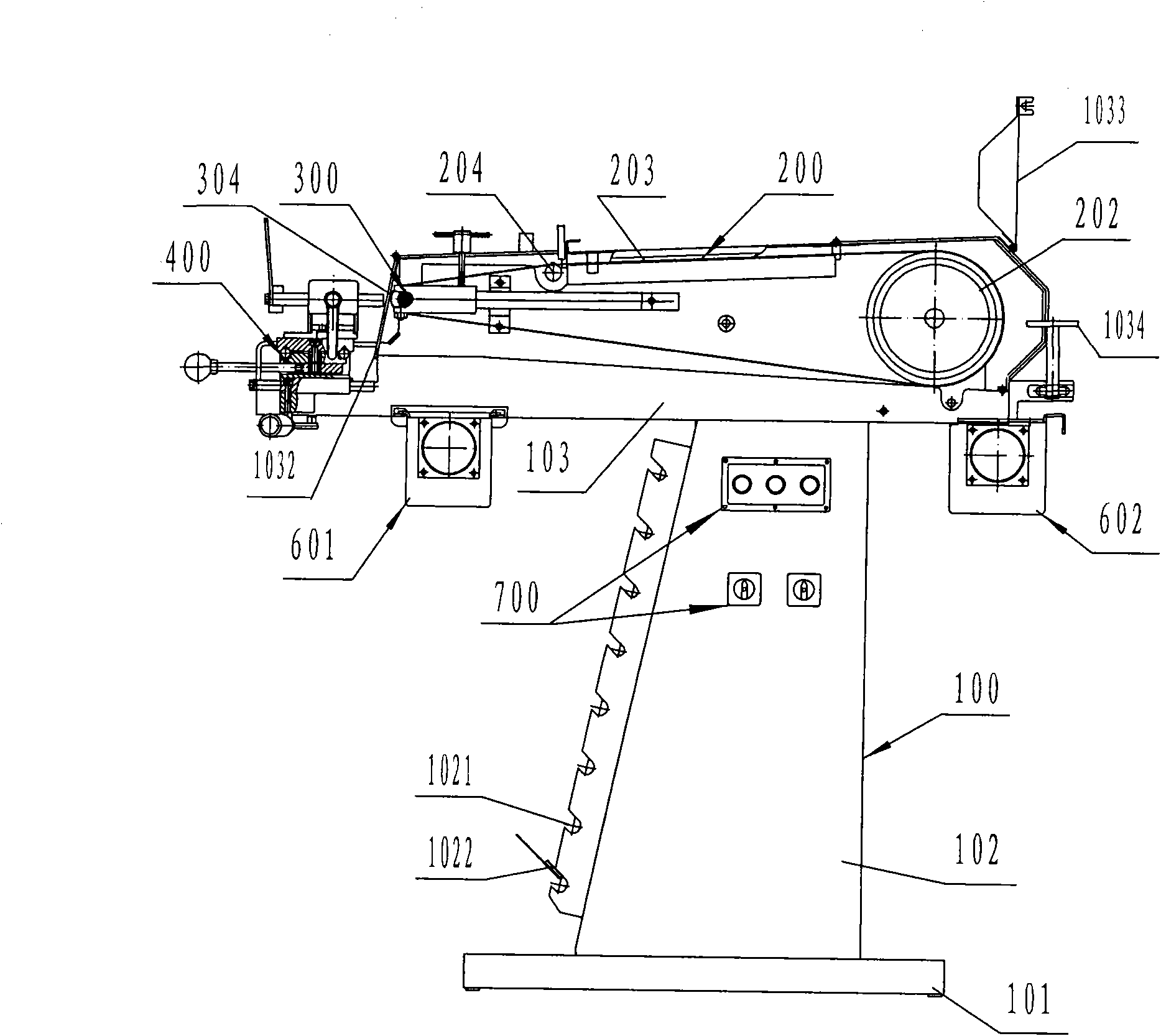

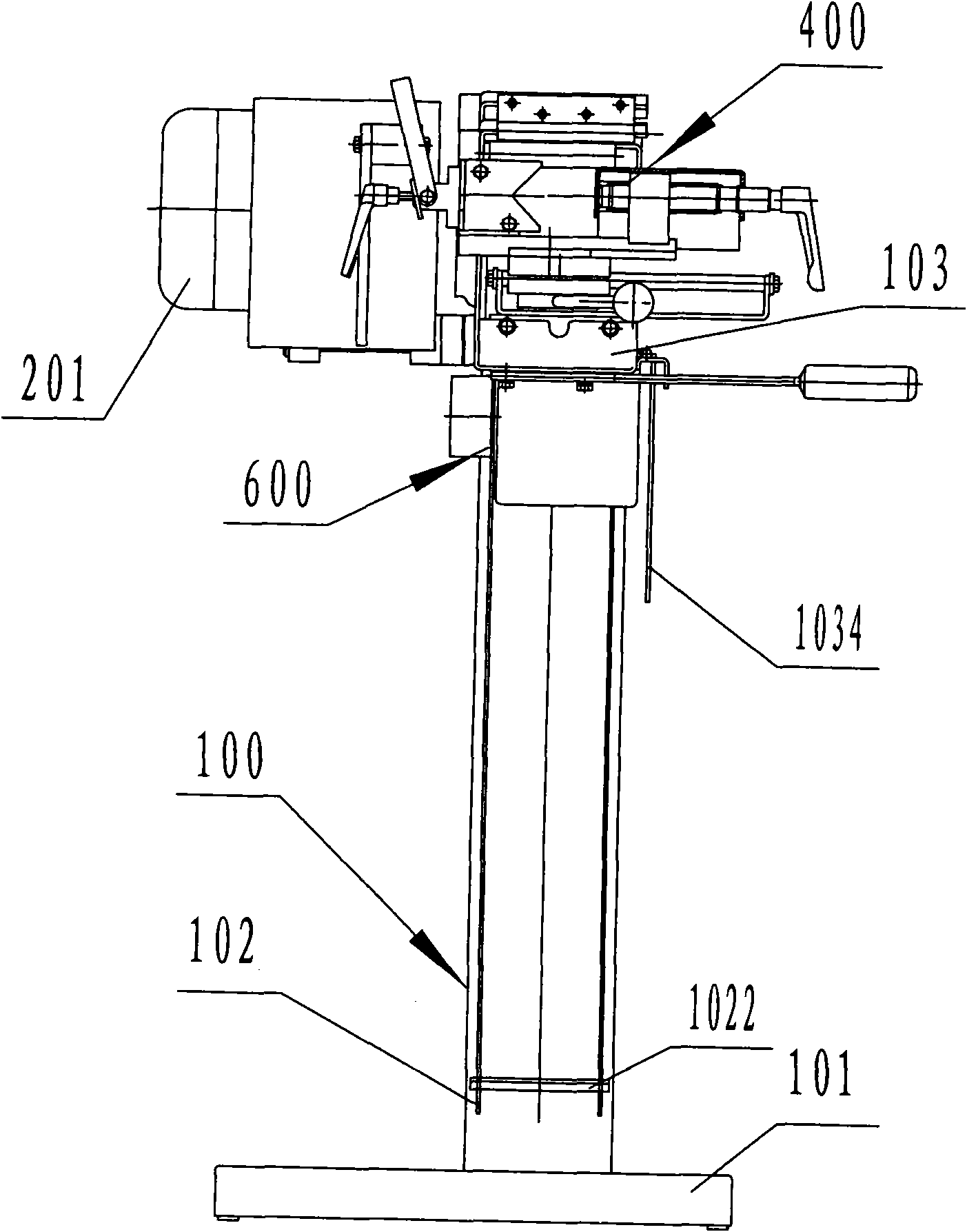

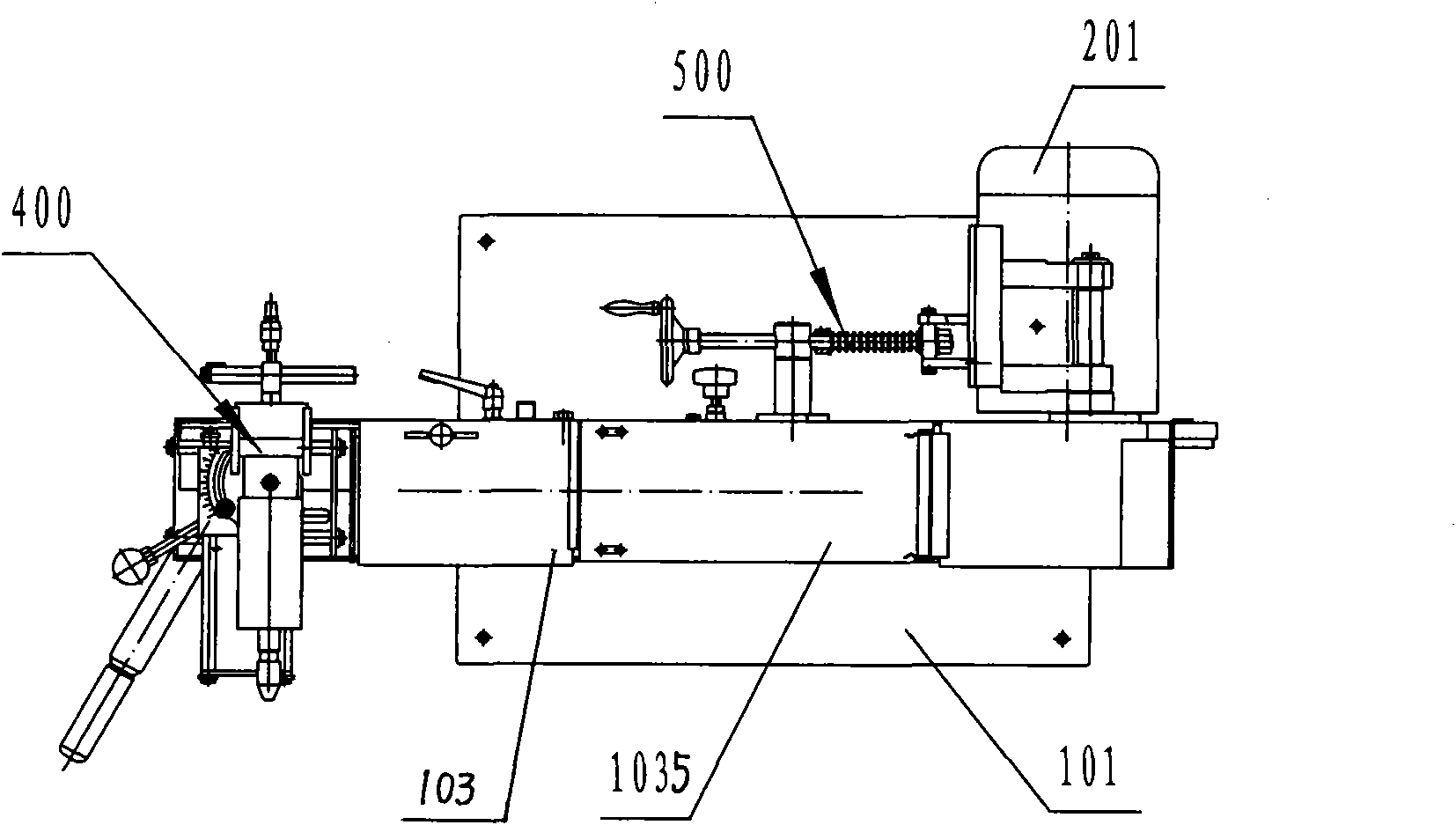

[0041] Depend on Figure 1a-Figure 1c It can be seen that the small multi-functional abrasive belt machine of the present invention is mainly composed of the following seven parts: a body part 100, a power part 200, a roller shaft adjustment mechanism 300, a workpiece clamping mechanism 400, an abrasive belt tensioning mechanism 500, a dust removal device 600, and an electrical appliance. Control system 700 . The structure of each of the following components is described in detail below:

[0042] (1) Body parts: refer to Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com