Intelligently-controlled high-purity ultra-fine aluminum powder atomization classification device specially used for aerospace, and technology thereof

An aerospace and intelligent control technology, applied in the field of aluminum powder atomization, can solve the problems of low fine powder rate, easy explosion, small particle size distribution, etc., to improve the forming rate and fine powder rate, avoid oxidation and explosion, The effect of improving the fine powder rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention aims to solve the technical bottleneck that the existing aluminum powder atomization device is difficult to realize the large-scale, safe and environmentally friendly production of ultrafine spherical atomized aluminum powder, and solves the problem according to the law of high-purity ultrafine spherical aluminum powder in the atomization process .

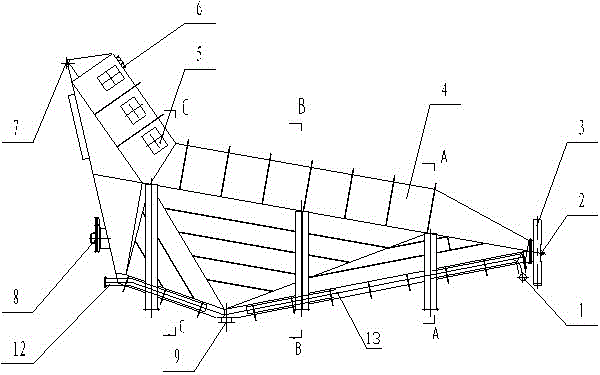

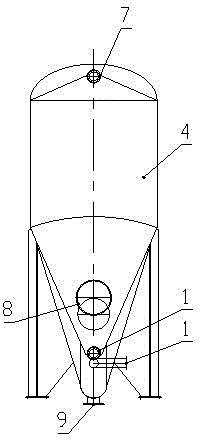

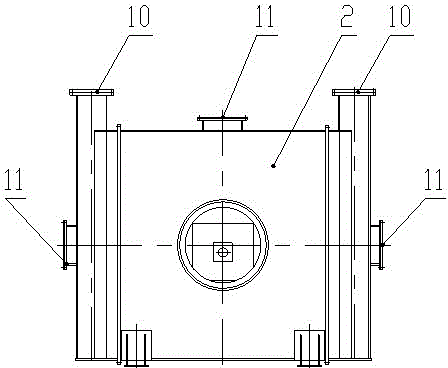

[0030] Such as figure 1 , 2 As shown, the present invention includes an atomization classification chamber 4, which is in a "V" shape. The right end of the atomization classification chamber 4 is connected to a cooling chamber 3, and the left end of the atomization classification chamber 4 is connected to a fine powder outlet 7. A coarse powder outlet 9 is provided at the bottom of the middle position of the classifying chamber 4 . A manhole 8 is also provided on the left side of the atomization classifying chamber 4 . The nitrogen fluidization air inlet 1 is arranged on the right side of the bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com