Efficient radial flow adsorption tower

An adsorption tower and radial flow technology, applied in the field of providing high-efficiency radial flow adsorption towers, can solve the problems of large equipment volume, high cost, and strict requirements for airflow distribution calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

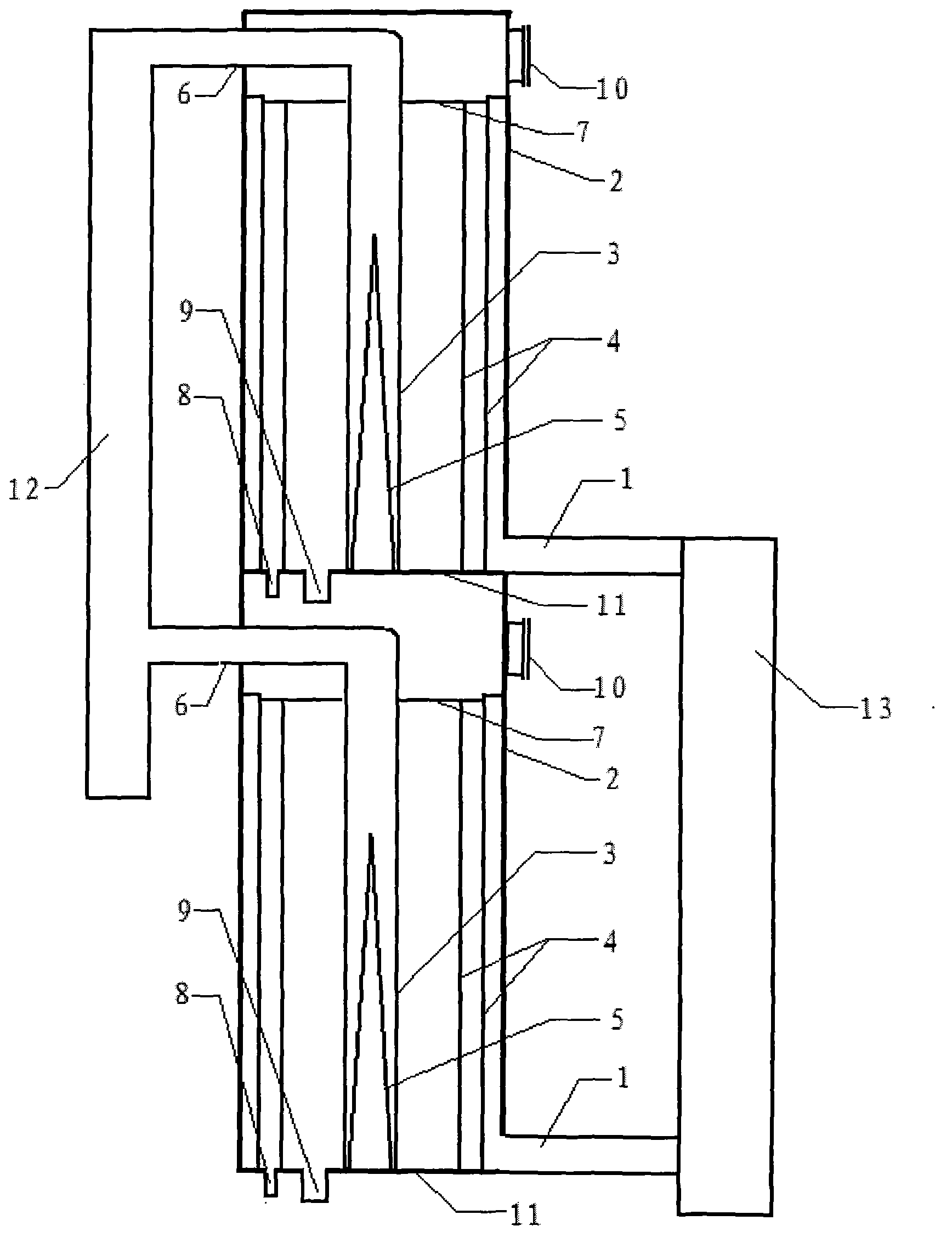

[0019] Embodiment, high-efficiency radial flow adsorption tower, consists of tangential air inlet (1), tower wall (2), central pipe (3), isolation cylinder (4), anti-dead zone guide cone cylinder (5), adsorption tail gas Outlet (6), adsorbent compression plate (7), auxiliary adsorbent discharge port (8), adsorbent discharge port (9), manhole (10), bottom plate (11), main pipe for adsorption tail gas (12 ), the main air intake duct (13) is formed. Each section of the adsorption tower is arranged in concentric circles from the outside to the inside by the tower wall (2), the isolation cylinder (4) and the center pipe (3). The top of the isolation cylinder (4) and the center pipe (3) passes through the adsorbent compression plate (7) Form the upper part of the adsorption section and seal; The central tube (3) forms an adsorption chamber, and the inner bottom of the central tube (3) is provided with an anti-dead zone guide cone (5); the bottom side of the tower wall (2) is connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com