Vacuum cleaner including muffler and air diffuser

A vacuum cleaner and muffler technology, which is applied in the direction of vacuum cleaners, exhaust diffusers, cleaning equipment, etc., can solve the problems of not allowing to reduce noise emissions, large size and volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

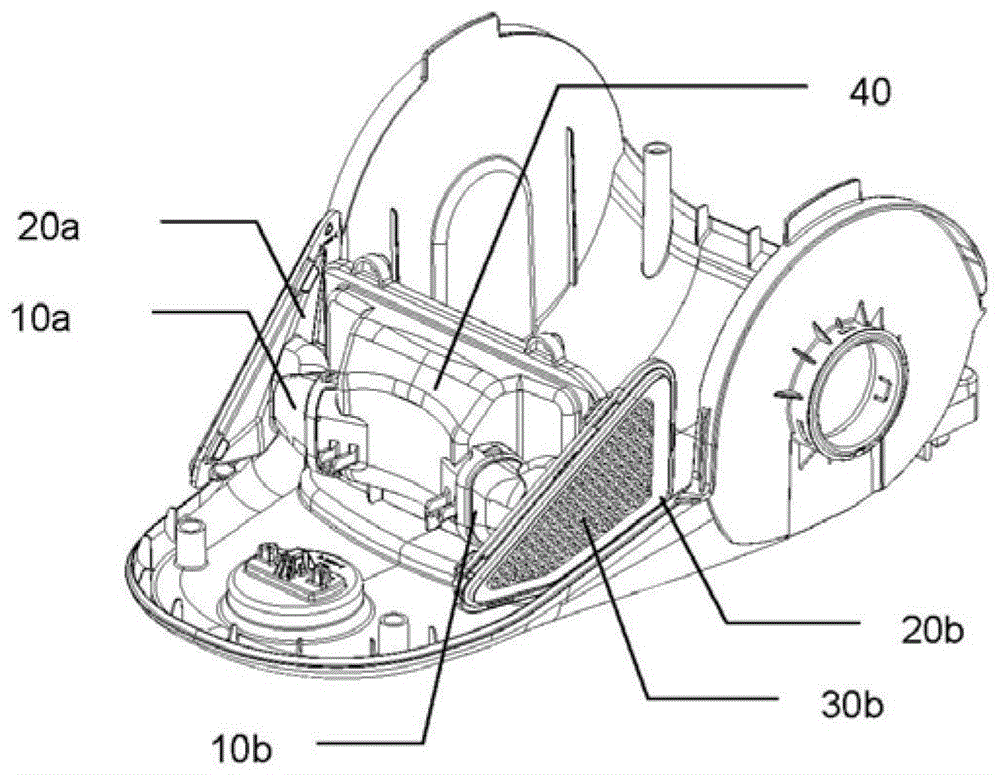

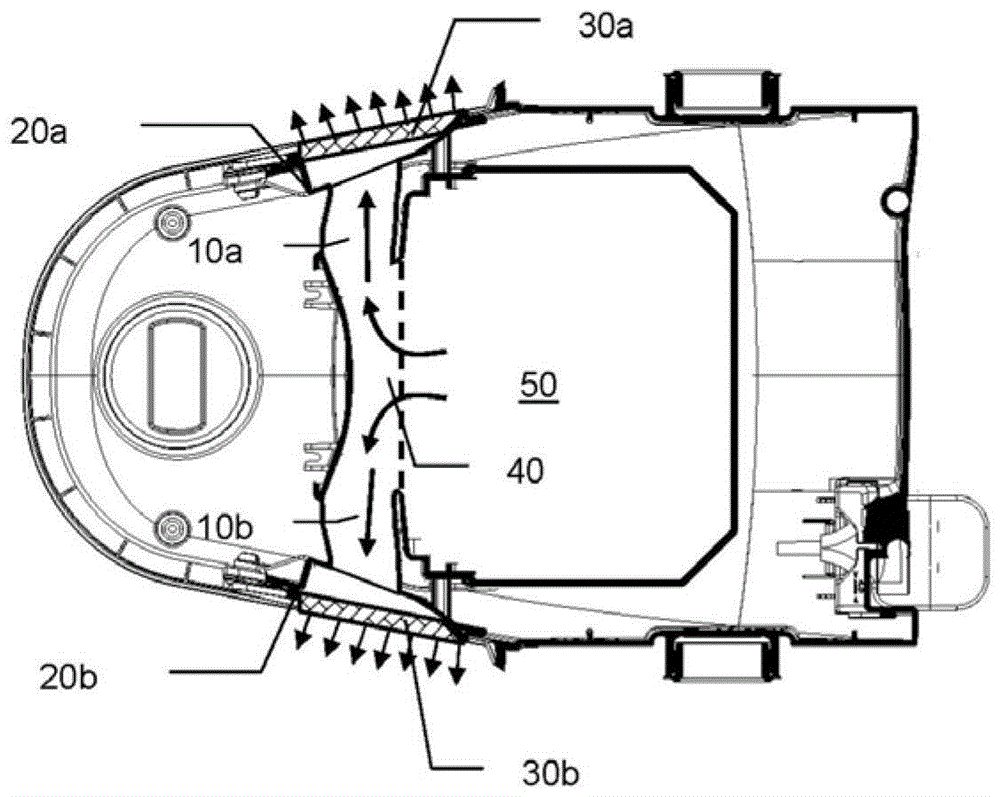

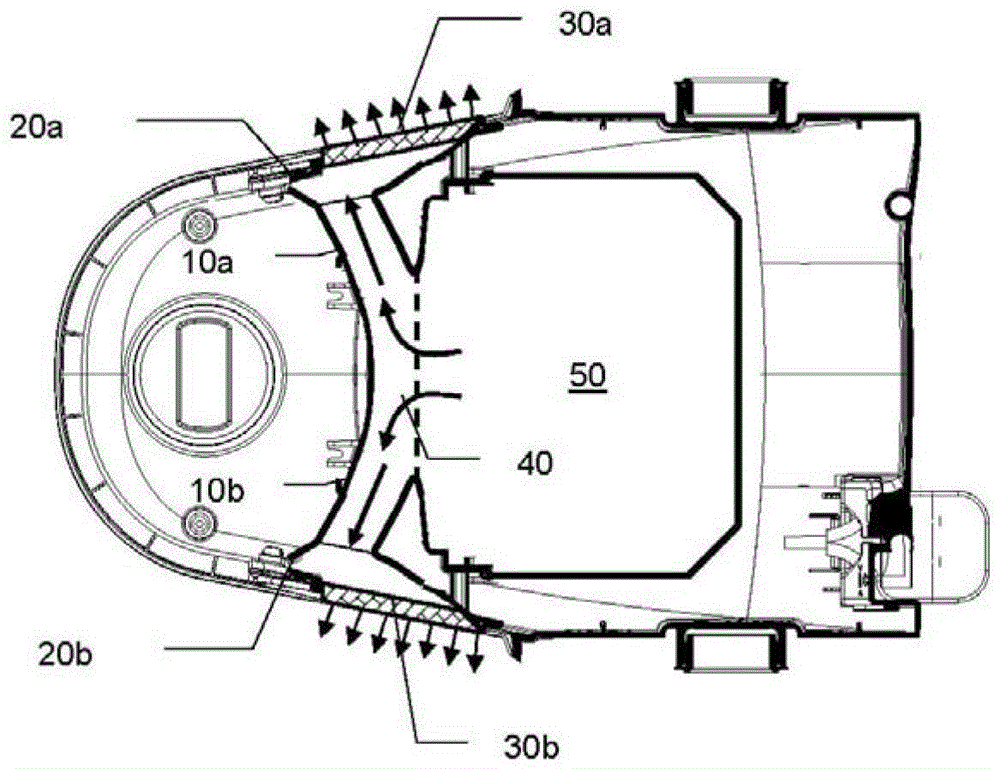

[0021] figure 1 Part of a vacuum cleaner is shown. The air collector 40 collects air exhausted by an unillustrated motor arranged at the rear of the cleaner. The collector 40 then distributes the air towards two exhaust circuits, each comprising a muffler formed by the elongated confinement portions 10a and 10b. The effect of these elongated limits of constant cross-section is to reduce the influence of the noise emitted by the air flow expelled by the motor. The two restricting parts 10a and 10b are then each connected to a porous diffuser 30a and 30b via two diffuse fitting parts 20a and 20b respectively, which are structural parts of the housing of the vacuum cleaner.

[0022] figure 2 show figure 1 Horizontal cutaway view of a vacuum cleaner. Thus, the motor 50 expels the air towards the collector 40, which then divides the air flow and directs it towards the two restricted portions 10a and 10b. Restriction portions 10a and 10b are connected to porous diffusers 30a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com