Method for reducing mask board splicing errors

A mask plate and error technology, which is applied to the photographic process of the pattern surface, the original for photomechanical processing, optics, etc., to achieve the effects of eliminating distortion processing, ensuring consistency, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

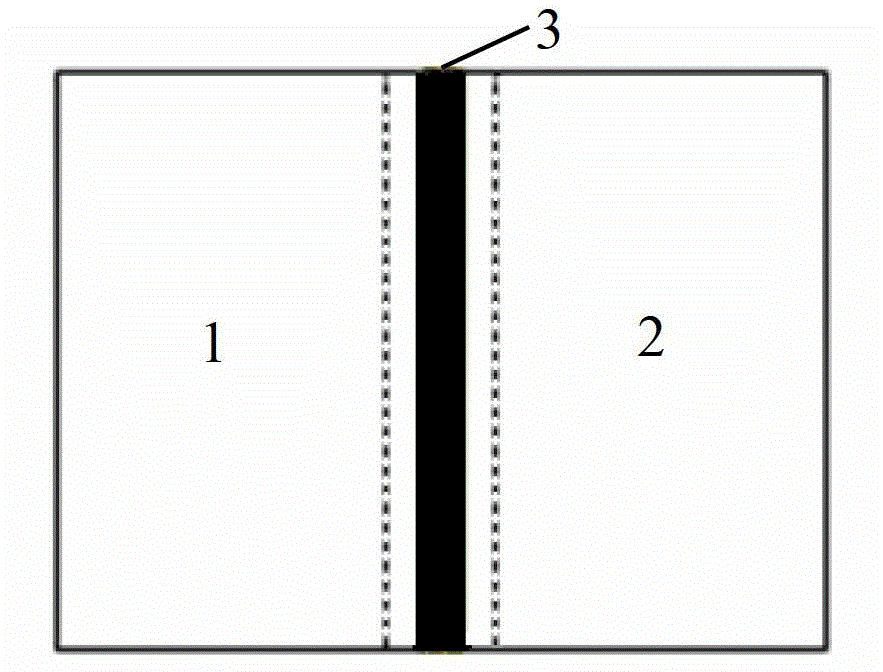

[0023] The method for reducing the splicing error of the mask plate provided in this embodiment is to reversely check all the patterns on the mask plate according to the result of the pattern formed by etching the exposure pattern on the splicing area of two adjacent masks after repeated exposure. Structural compensation is performed on the exposure pattern of the spliced region. The so-called reverse compensation is to perform structural compensation opposite to the result of the graph.

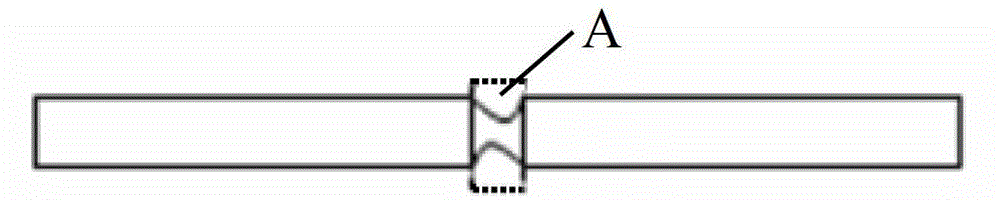

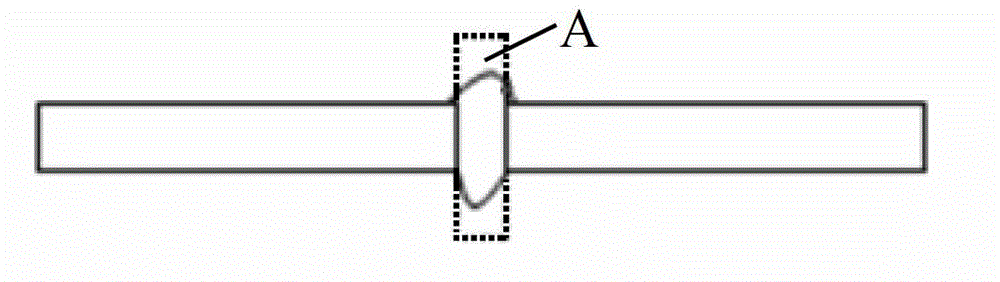

[0024] Specifically, for figure 2 The phenomenon that the etched pattern A of the exposure pattern on the splicing area 3 formed after repeated exposure is narrower than the patte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com