Flexible supporting mechanism for reflector of spatial optical remote sensor

A space optical remote sensing and flexible support technology, which is applied in the field of space remote sensing, can solve the problems affecting the surface shape of the mirror and the difficulty in ensuring the axial stiffness of the mechanism, etc., and achieve the effects of reducing difficulty, easy processing and assembly, and reducing temperature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

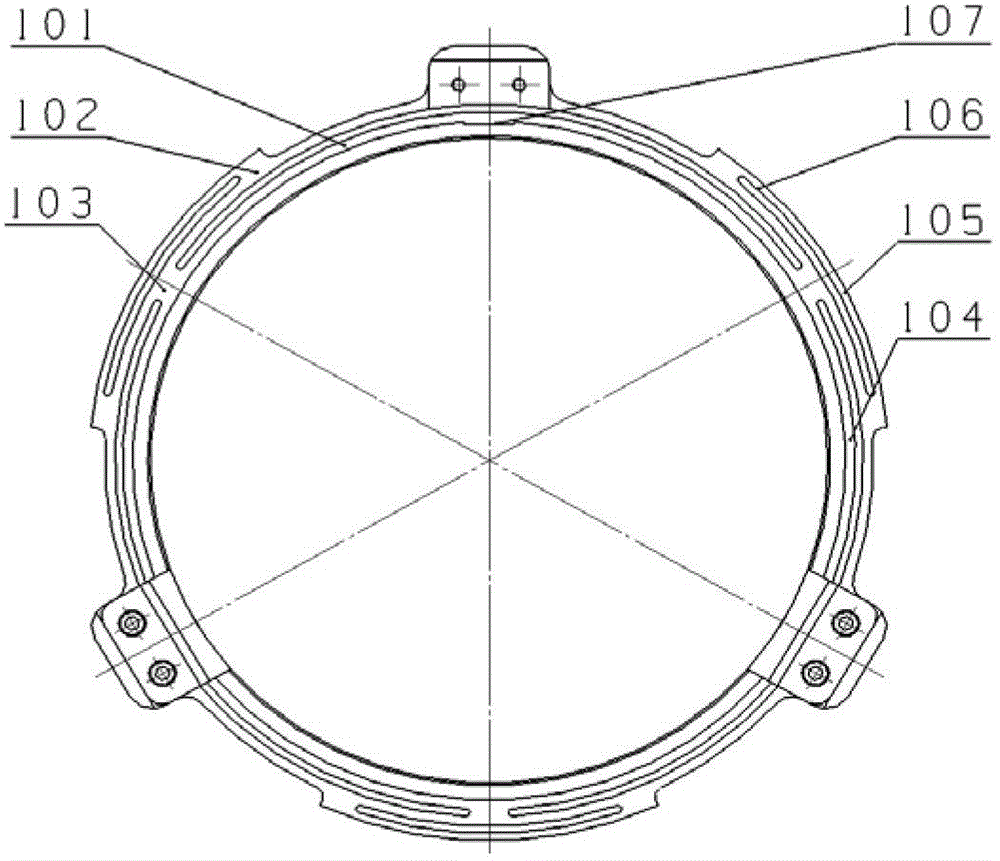

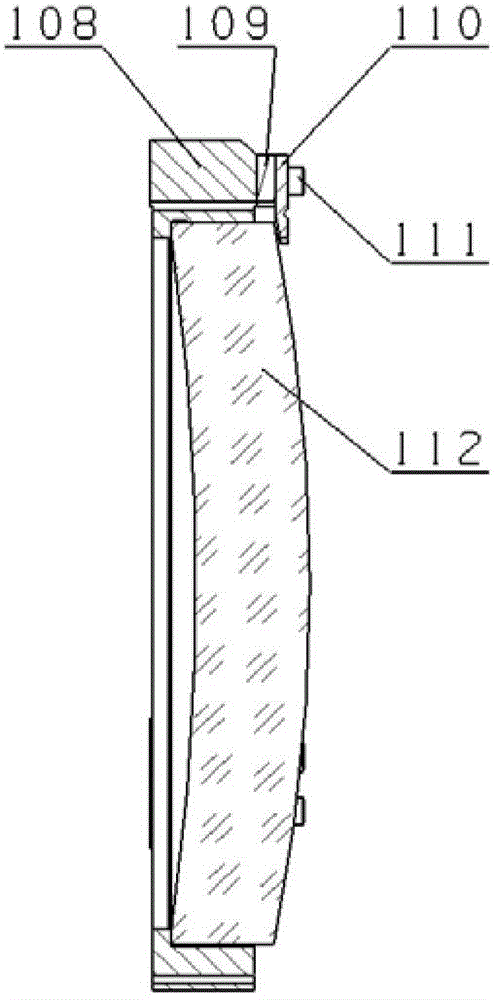

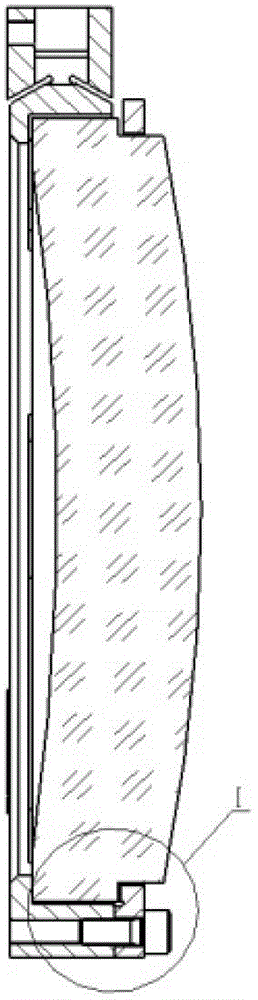

[0029] Such as Figure 3-7 As shown, the space optical remote sensor reflector flexible support mechanism of the present invention comprises: reflector 1, gasket 2, screw 3, annular pressure plate 4, reflector frame 5; Wherein, reflector frame 5 comprises: inner ring boss 6, Glue injection hole 7, bottom ring boss 8, radial flexible groove 9, radial flexible groove 11, radial flexible joint 10, axial flexible groove 12, axial flexible groove 14, axial flexible joint 13, threaded hole 15 , threaded hole 16, square hole 17, outer ring boss A ( Figure 5 The part shown in A) and the outer ring boss B ( Figure 5 part shown in B). On the reflector frame 5, three outer ring bosses A and three outer ring bosses B uniformly distributed at 120° are staggered at 60°; the upper end surface of the outer ring boss A has threaded holes 15, ring The pressing piece 4 is connected with the reflector frame 5 through three threaded holes 15; the outer ring boss B is a cuboid structure connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com